Innovative Solutions for Semi-Conductive Test Fixture Manufacturing and Design

The Importance of Semi-Conductive Test Fixture Manufacturers in the Electronics Industry

In the rapidly evolving world of electronics, the significance of reliable testing equipment cannot be overstated. One of the critical components in ensuring the quality and performance of electronic devices is the semi-conductive test fixture. As the backbone of the testing process, these fixtures play a vital role in various applications, from research and development to mass production. This article delves into the importance of semi-conductive test fixture manufacturers and the impact they have on the electronics industry.

Understanding Semi-Conductive Test Fixtures

Semi-conductive test fixtures are specialized setups designed to facilitate the testing of electronic components and assemblies. They provide the necessary interface between testing equipment and the devices under test (DUT). By ensuring accurate electrical connections, these fixtures enable engineers to obtain precise measurements, which are crucial for evaluating performance, reliability, and safety.

The design and manufacturing of these test fixtures require a deep understanding of both electrical engineering principles and the specific requirements of the components being tested. This intricate balance is why dedicated semi-conductive test fixture manufacturers are essential. They combine advanced technology with industry expertise to create fixtures that meet rigorous standards.

The Role of Manufacturers in the Testing Ecosystem

The role of semi-conductive test fixture manufacturers extends beyond mere production. They are critical partners in the testing ecosystem, contributing to the following areas

1. Customization Different electronic components have unique characteristics and requirements. Manufacturers work closely with clients to develop customized solutions that cater to specific testing needs. Whether it’s designing a fixture for a new semiconductor package or adapting existing designs for different test conditions, customization is a key offering.

2. Quality Assurance Quality control is paramount in the electronics industry. Manufacturers ensure that their test fixtures are built to high standards, enabling accurate and reliable testing. This assurance not only boosts product quality but also enhances the overall credibility of the testing process.

3. Innovation The electronics field is characterized by rapid advancements. Test fixture manufacturers are at the forefront of embracing new technologies, such as automation and integrated diagnostic functionalities. By integrating cutting-edge materials and design principles, manufacturers help improve testing efficiency and accuracy.

4. Cost Efficiency While investing in quality test fixtures may seem costly initially, the long-term benefits often outweigh the expenditure. Properly designed fixtures can minimize test times, reduce error rates, and ultimately lead to significant cost savings in the production process. Manufacturers understand these dynamics and aim to provide solutions that balance cost and quality.

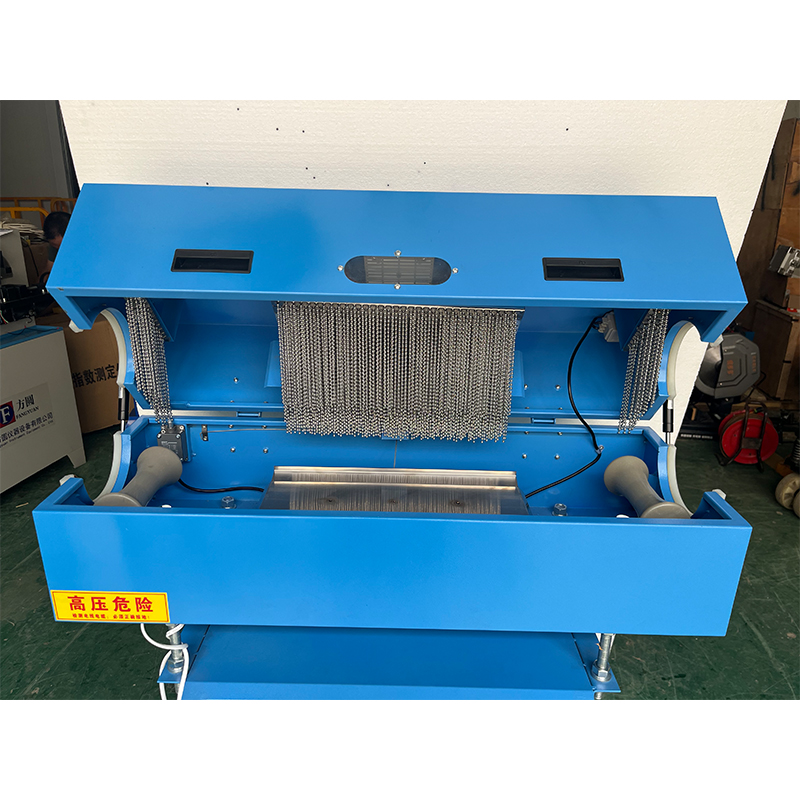

semi-conductive test fixture manufacturer

Challenges Faced by Manufacturers

Despite their importance, semi-conductive test fixture manufacturers face numerous challenges. One significant hurdle is keeping pace with the rapid technological advancements in the electronics industry. As devices become more complex, manufacturers must continuously innovate and adapt their designs to accommodate new testing requirements.

Another challenge is the increasing demand for sustainability and environmental responsibility. Manufacturers are now called upon to consider eco-friendly materials and processes in fixture production. Meeting these demands while ensuring product performance creates a delicate balancing act.

Selecting the Right Manufacturer

Choosing the right semi-conductive test fixture manufacturer is crucial for businesses aiming to enhance their testing capabilities. Key factors to consider include

- Expertise and Experience Look for manufacturers with a proven track record in designing and producing semi-conductive test fixtures. Their experience in a range of applications will be beneficial.

- Customization Capabilities Select manufacturers that offer tailored solutions to meet specific testing needs.

- Quality Standards Ensure that the manufacturer adheres to recognized quality standards in production processes.

- Customer Support Reliable customer support can help resolve challenges during implementation and operation.

Conclusion

In summary, the role of semi-conductive test fixture manufacturers is critical in the electronics sector. They provide the necessary tools for quality assurance, innovation, and cost efficiency in testing processes. By understanding their significance, businesses can make informed decisions that enhance their testing capabilities and, ultimately, contribute to the success of their electronic products in the marketplace. As technology continues to evolve, the partnership between manufacturers and electronic companies will remain a cornerstone of the industry's advancement.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy