semi-conductive test fixture supplier

Understanding the Importance of Semi-Conductive Test Fixtures in the Electronics Industry

In today’s fast-paced electronics industry, the reliability and performance of semiconductor devices have become increasingly critical. The rise of sophisticated electronic products demands thorough testing regimes to ensure quality and functionality. This is where semi-conductive test fixtures come into play. These specialized testing tools are essential for validating the performance of semiconductor devices before they reach consumers. In this article, we will explore the significance of semi-conductive test fixtures, their applications, and the suppliers that provide these crucial components.

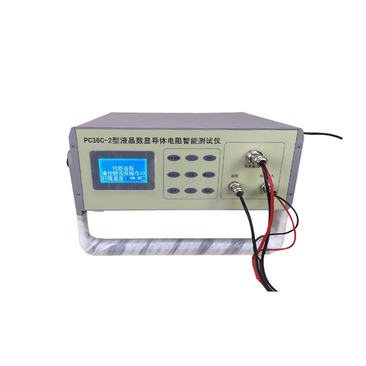

A semi-conductive test fixture is essentially a specialized apparatus designed to hold semiconductor devices in place while testing their electrical properties. These fixtures allow engineers and technicians to connect the semiconductor to testing equipment without causing damage, ensuring that accurate measurements can be taken. The geometry and materials of the test fixture greatly influence the test results, making the selection of the right fixture vital for achieving reliable and reproducible data.

One of the primary functions of a semi-conductive test fixture is to facilitate the electrical connections required for testing various semiconductor parameters, such as voltage, current, and frequency. Whether testing integrated circuits, transistors, or diodes, a well-designed test fixture ensures that the device under test (DUT) can be easily connected to the relevant testing equipment. This process typically involves a series of probes and connectors that interface with the semiconductor device while shielding it from external interference.

Applications for semi-conductive test fixtures are vast and varied. In the research and development phase of semiconductor design, these fixtures are crucial for characterizing new devices and their operational behaviors. Testing laboratories and production lines employ semi-conductive test fixtures to ensure that their products meet industry standards and customer expectations. Furthermore, these fixtures are used in failure analysis, where engineers investigate why a particular semiconductor component malfunctioned.

semi-conductive test fixture supplier

The choice of a semi-conductive test fixture supplier is critically important for businesses aiming to optimize their testing processes

. The supplier should not only provide high-quality fixtures but also offer customization options to accommodate the unique requirements of different testing scenarios. Factors to consider when selecting a supplier include their reputation, experience in the industry, and technical support capabilities. A reliable supplier can provide guidance on fixture design, ensuring that the final product aligns with specific testing protocols and equipment specifications.Suppliers of semi-conductive test fixtures typically offer a range of products, from standard models to highly customized solutions. The standard fixtures are designed for general testing applications, while custom solutions can be developed to meet specific performance criteria or to fit particular device shapes and sizes. Many suppliers engage in continuous innovation, incorporating advances in materials and technology to improve their fixtures’ performance, durability, and usability.

Moreover, as the electronics industry moves towards miniaturization and increased complexity, the demand for high-precision semi-conductive test fixtures has surged. Suppliers are now investing in advanced manufacturing techniques, such as 3D printing and computer-aided design (CAD), to meet these evolving needs. This allows for the rapid prototyping of fixtures, enabling companies to test new designs quickly and efficiently.

In conclusion, semi-conductive test fixtures play a critical role in ensuring the quality and performance of semiconductor devices across various applications in the electronics industry. Selecting the right supplier for these fixtures is essential for any organization focused on delivering high-quality products. By partnering with experienced and reliable fixture suppliers, companies can enhance their testing processes, leading to improved product reliability, lower failure rates, and ultimately, greater customer satisfaction. As the industry continues to evolve, the importance of semi-conductive test fixtures will only grow, making them an integral part of the semiconductor testing landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy