single cable burning tester factory

Single Cable Burning Tester Factory Ensuring Safety and Reliability in Electrical Components

In today’s fast-paced technological landscape, the demand for high-quality electrical components is greater than ever. Whether used in building infrastructure or in intricate electronic devices, the safety and reliability of cables are paramount. This necessity has led to the emergence of specialized testing facilities, such as single cable burning tester factories. These facilities are dedicated to ensuring that electrical cables meet stringent safety standards and perform efficiently in real-world applications.

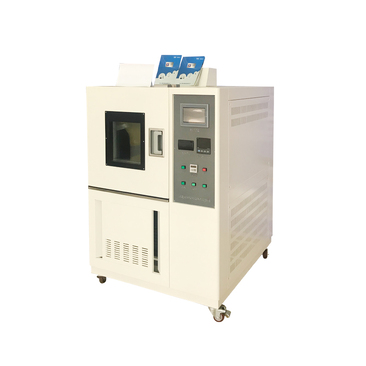

A single cable burning tester is a crucial device used to assess the fire resistance and performance of electrical cables. It simulates real-life fire conditions to determine how cables react when exposed to flames. This testing is essential for complying with international safety standards, protecting both consumers and industries from potential hazards. In a single cable burning tester, the cable is subjected to high temperatures while measuring the extent of damage, smoke emissions, and the release of toxic gases.

The testing procedure in a factory setting is meticulously designed to replicate a variety of fire scenarios. The factory personnel are skilled technicians who follow standardized testing protocols to ensure accuracy and consistency. A single cable burning tester typically incorporates features that allow for precise control over temperature, flame size, and exposure duration. Thus, the results obtained provide valuable data on the fire performance characteristics of the cables being tested.

One of the most critical aspects of a single cable burning tester factory is adherence to safety regulations

. The facility must maintain a controlled environment with adequate safety measures in place. This includes fire suppression systems, personal protective equipment for workers, and proper ventilation to manage smoke and gases released during testing. Additionally, the factory implements rigorous quality control processes to monitor equipment functionality and ensure that all tests are carried out according to established guidelines.single cable burning tester factory

The significance of the findings from a single cable burning tester cannot be overstated. An electrical cable that passes testing demonstrates a higher level of fire resistance, minimizing the risk of fire hazards in buildings, automobiles, and various applications where cables are used. Consequently, manufacturers can market their products with increased confidence, knowing that they meet or exceed safety standards. This not only protects consumers but also enhances the manufacturer's reputation and competitiveness in the market.

Moreover, the insights gained from testing can inform improvements in cable design and materials. By understanding how different cables perform under fire conditions, manufacturers can innovate and create better products that are not only safer but also more efficient. For example, using advanced materials with improved fire-retardant properties can significantly enhance the safety profile of electrical cables.

The factory process is also dynamic and continuously evolving. With advancements in technology, single cable burning tester factories are assured to integrate more sophisticated testing techniques and equipment. This evolution allows for more thorough assessments, addressing the ever-changing standards and regulations in the electrical industry.

In conclusion, single cable burning tester factories play a critical role in the electrical component industry by ensuring that cables are tested for fire safety and reliability. By simulating fire conditions and analyzing the results, these facilities help manufacturers produce high-quality, safe products for consumers. Ultimately, their work not only protects lives and property but also fosters innovation within the industry, paving the way for more dependable electrical solutions in the future. As technology progresses, the significance of such testing facilities will only continue to grow, emphasizing the commitment to safety and excellence in manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy