single cable burning tester supplier

The Importance of Single Cable Burning Testers and Their Suppliers

In today's technology-driven world, the demand for reliable and safe electrical products has never been higher. As we become increasingly dependent on electrical devices, ensuring their safety during operation becomes paramount. One critical aspect of this safety assurance process is the testing of electrical cables under extreme conditions. This is where single cable burning testers play an essential role.

What is a Single Cable Burning Tester?

A single cable burning tester is a specialized device used to evaluate the fire resistance and thermal characteristics of cables when subjected to high temperatures. This type of tester typically simulates conditions that cables may encounter in real-world scenarios, where overheating or electrical faults could lead to fire hazards. By assessing how a cable reacts to extreme heat—whether it degrades, ignites, or emits toxic fumes—manufacturers can ensure compliance with safety standards and regulations.

Why Testing Matters

The importance of testing cables cannot be overstated. Cables are often the backbone of electrical installations, powering everything from residential lighting to industrial machinery. The consequences of a cable failure can be catastrophic, leading not only to property damage but also to potential loss of life. By employing single cable burning testers, manufacturers can proactively identify weaknesses in their products, enhancing safety and reliability.

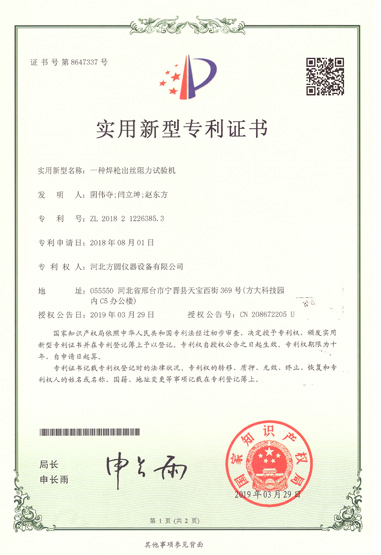

Moreover, regulatory bodies around the world impose stringent testing requirements for electrical products. Compliance with these regulations is not just a legal obligation; it's a fundamental aspect of responsible manufacturing. A reputable supplier of single cable burning testers will help manufacturers ensure that their cables meet necessary standards, avoiding costly recalls and liability issues down the line.

Choosing a Supplier

When selecting a supplier for single cable burning testers, several factors need to be taken into account

single cable burning tester supplier

1. Quality and Reliability The supplier's equipment should adhere to international testing standards and be capable of providing accurate, repeatable results. A reliable tester will help manufacturers build confidence in their product’s safety.

2. Expertise and Support A good supplier will not only offer testing equipment but also expertise and support. They should provide guidance on how to conduct tests properly and interpret results, ensuring that manufacturers can fully utilize the equipment.

3. After-Sales Service Consider suppliers that offer comprehensive after-sales support, including maintenance and calibration services. This is crucial for ensuring that the testing equipment remains in optimal working condition over time.

4. Customization Options Different manufacturing processes may require specific testing configurations. A competent supplier will offer customizable solutions tailored to meet the unique needs of their clients.

5. Reputation in the Industry Research the supplier's track record in the industry. Reviews and testimonials from other manufacturers can provide insights into the supplier's reliability and performance.

Conclusion

As industries evolve and the standards for safety continue to tighten, the role of single cable burning testers becomes increasingly crucial. Suppliers of these testers are responsible for providing manufacturers with the tools necessary for ensuring cable safety. By understanding the importance of testing and choosing the right supplier, manufacturers can not only enhance the safety of their products but also boost their market reputation.

Investing in quality testing equipment and expertise will ultimately benefit manufacturers in the long run. By ensuring that their products can withstand the rigors of everyday use, they not only protect themselves from liability but also safeguard the lives of consumers who rely on their products. In a world where safety is paramount, the role of single cable burning tester suppliers is indispensable.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy