single cable combustion tester

Single Cable Combustion Tester Ensuring Safety and Compliance in Cable Manufacturing

In today's technologically advanced world, the demand for reliable and safe electrical cabling systems is more significant than ever. As we increasingly depend on electrical equipment in both industrial and domestic settings, the safety of cable materials comes to the forefront. One critical piece of equipment that facilitates this safety is the single cable combustion tester. This device is designed to evaluate the flammability and combustion characteristics of single insulated cables, ensuring that they comply with international safety standards.

The single cable combustion tester operates on the principles of combustion science, which assesses how materials ignite, burn, and emit smoke and toxic gases when subjected to an open flame. The results derived from these tests are vital for manufacturers in the cable industry as they provide essential data that influences product design, material selection, and regulatory compliance.

Functionality of the Tester

The single cable combustion tester is equipped to measure various parameters during the combustion process. When a cable sample is exposed to a controlled flame, the tester records important metrics such as burn time, flame spread rate, and smoke generation. These parameters are critical in determining how safe a cable is when exposed to fire. The tester mimics real-world scenarios where cables might be exposed to flames, providing manufacturers with realistic data that can help enhance the safety of their products.

Importance of Compliance

Compliance with standards such as the National Fire Protection Association (NFPA) and International Electrotechnical Commission (IEC) is essential for cable manufacturers. These standards set forth requirements regarding the reaction of cables when exposed to fire, including the amount of smoke generated and the toxicity of any fumes produced. By utilizing a single cable combustion tester, manufacturers can ensure that their products meet these stringent standards, thereby minimizing risks associated with electrical fires.

single cable combustion tester

Furthermore, regulatory compliance is not just about meeting legal obligations; it has direct implications for consumer safety. Cables that do not pass ignition tests may pose significant risks in residential, commercial, and industrial applications. By rigorously testing cables with combustion testers, manufacturers actively contribute to increases in public safety and prevention of fire hazards.

Applications Beyond Compliance

While compliance with safety standards is a primary reason for using single cable combustion testers, their applications extend beyond mere regulation. The data obtained from these tests can guide innovation in cable design. For instance, manufacturers can explore the use of flame-retardant materials or coatings that inhibit flame spread, thus enhancing the overall safety profile of their products.

Moreover, in the automotive and aerospace industries, where the consequences of fire can be catastrophic, cable safety testing becomes even more crucial. The functionality of vehicles and aircraft relies on the integrity of wiring systems. A malfunction due to thermal effects or combustion can lead to failures that endanger lives. Thus, thorough testing ensures that cables in these high-stakes environments can withstand extreme conditions without compromising safety.

Conclusion

In conclusion, the single cable combustion tester plays an indispensable role in the cable manufacturing industry. As we continue to rely on electrical cables in our everyday lives, the importance of ensuring their safety through rigorous testing cannot be overstated. By adhering to safety standards and leveraging the insights gained from combustion testing, manufacturers can produce cables that not only comply with regulations but also contribute to a safer environment for all.

Investing in quality testing equipment like the single cable combustion tester is a proactive approach that can foster innovation while protecting consumers from potential hazards associated with electrical fires. As technology evolves, so too must the methods employed to ensure that safety remains at the forefront of cable production processes. In this way, the single cable combustion tester is not just a tool for compliance but a foundational element in the ongoing commitment to safety and excellence in the cable manufacturing industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

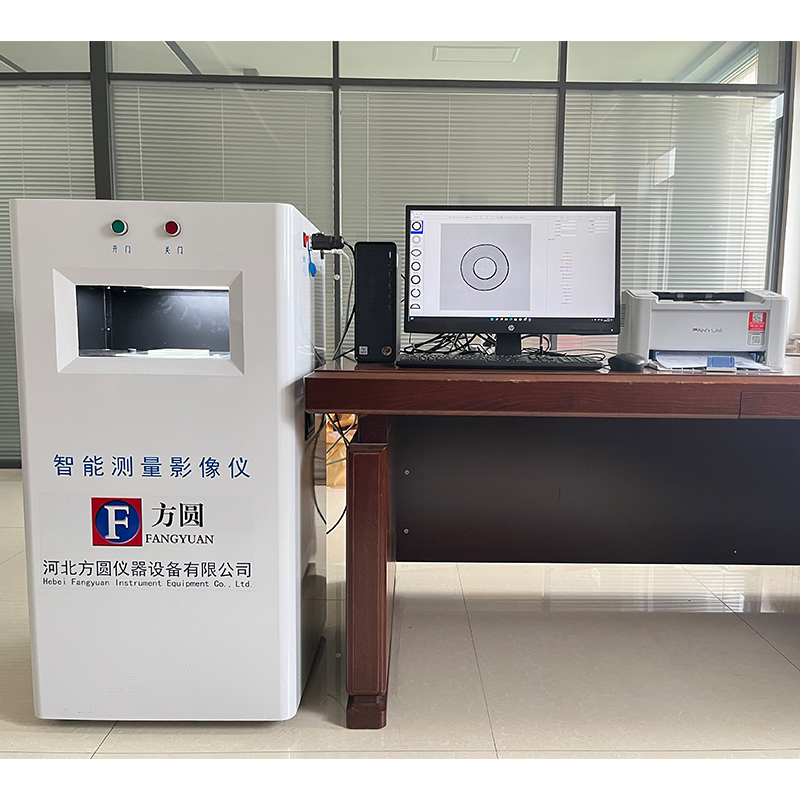

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy