Single Cable Fire Test Equipment Provider for Safety Assessments and Compliance Solutions

The Importance of Single Cable Combustion Testers A Comprehensive Overview

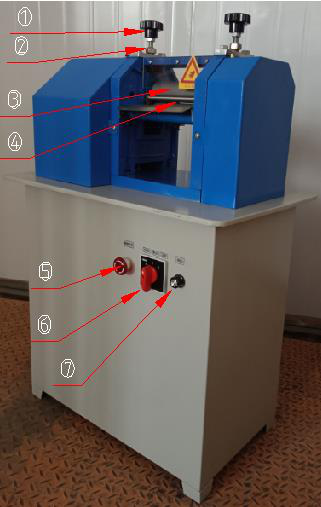

In the ever-evolving landscape of electrical engineering and safety protocols, the significance of cable testing cannot be overstated. One of the crucial tools in this realm is the single cable combustion tester, a device designed to assess the flammability and fire hazard potential of electrical cables. This article delves into the importance of such testers, their functionality, and the role of suppliers in ensuring safety standards are met across various industries.

Understanding Single Cable Combustion Testers

Single cable combustion testers are specialized instruments used to evaluate the reaction of electrical cables when exposed to fire. The testers measure how cables burn and the characteristics of the combustion, such as smoke production and the release of harmful gases. These evaluations are critical as they inform manufacturers, engineers, and safety regulators about the combustibility of the materials used in cables, ultimately leading to safer electrical installations.

The standard method of testing involves subjecting a single cable sample to a controlled flame and observing its combustion behavior. Parameters such as burn rate, flame spread, and the toxicity of emitted smoke are meticulously recorded. These factors are essential in determining whether a cable meets national and international fire safety standards.

Significance of Testing

The implications of using substandard cables can be catastrophic, leading to property damage, loss of life, and legal repercussions for manufacturers and installers. Therefore, investing in high-quality single cable combustion testers and adhering to rigorous testing protocols is non-negotiable for any organization involved in the production or use of electrical cables.

Compliance with safety standards, such as the National Fire Protection Association (NFPA) and Underwriters Laboratories (UL), is not only a legal requirement but also a moral obligation to protect consumers and workers. Regular testing ensures that cables can withstand various environmental conditions and do not pose a significant fire risk, thereby promoting overall safety in homes, industries, and public spaces.

Choosing the Right Supplier

single cable combustion tester supplier

Selecting a reliable supplier for single cable combustion testers is a critical decision that can impact the efficacy of testing processes. A reputable supplier should offer high-quality equipment that is compliant with relevant safety standards. It is advisable to consider suppliers with a proven track record in the industry and those who offer excellent customer support.

When evaluating potential suppliers, it is essential to examine the following criteria

1. Product Quality The tester's construction and capabilities should align with international standards. Look for certifications and endorsements from governing bodies. 2. Technical Expertise Suppliers should not only provide equipment but also possess the technical know-how to assist clients in proper testing methodologies.

3. After-Sales Support Quality after-sales support is crucial for maintenance, calibration, and troubleshooting, ensuring that the testing equipment remains in optimal condition.

4. Education and Training Some suppliers offer training services to help personnel understand how to use testers effectively, making it a valuable addition to any procurement.

5. Reputation and Reviews Researching customer reviews and testimonials can provide insights into a supplier’s reliability and the effectiveness of their products.

Conclusion

In summary, single cable combustion testers are vital tools in the electrical industry, ensuring that cables are safe for use and compliant with fire safety standards. As fires caused by electrical faults can have devastating consequences, manufacturers and engineers must prioritize the testing of cables to mitigate risks. Choosing the right supplier for these testing devices is equally important, as it ensures that organizations have access to high-quality equipment and technical support. By prioritizing safety and investing in robust testing procedures, industries can protect lives, property, and their reputations—creating a safer world for everyone.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy