Smoke Density Chamber Testing for Export Quality Assessment in Fire Safety Standards

Smoke Density Chamber Test An Essential Tool for Material Safety

The safety and performance of materials in various applications, particularly in construction and automotive industries, are paramount in today's world. One crucial aspect of assessing these materials is their smoke density, which can significantly impact fire safety. The smoke density chamber test has emerged as a vital method for quantifying the smoke production of materials when exposed to fire, and understanding this test is vital for manufacturers, engineers, and safety professionals.

Understanding Smoke Density

Smoke density refers to the amount of smoke produced per unit volume during combustion. In the event of a fire, smoke can pose serious hazards to occupants of a building or passengers in a vehicle. High smoke density materials can lead to reduced visibility and increased toxicity, complicating evacuation efforts and rescue operations. Therefore, measuring smoke density is essential for determining the fire safety performance of materials.

The Smoke Density Chamber Test

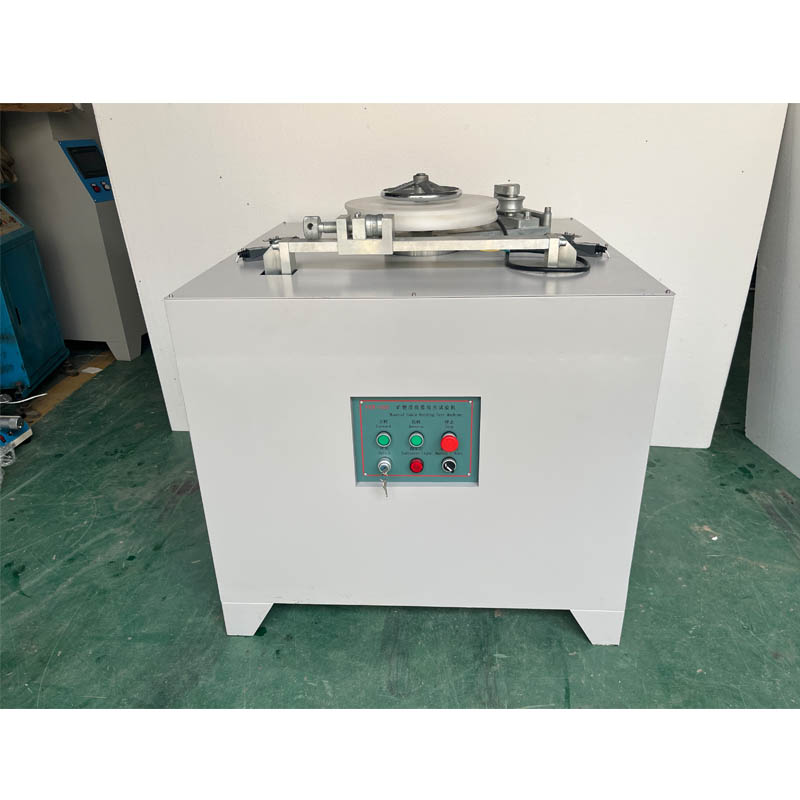

The smoke density chamber test evaluates the amount of smoke produced by a material when it is subjected to a controlled flame. This test is typically conducted in a smoke density chamber, a specialized enclosure designed to contain smoke and facilitate accurate measurements of its density over time. During the test, a sample of the material is ignited in a controlled environment, and the smoke produced is collected and analyzed.

The results of the test are usually expressed in terms of specific optical density (D) over time, allowing for a standardized comparison between different materials

. The higher the smoke density value, the greater the potential risk associated with that material in the event of a fire.Importance for Compliance and Safety

smoke density chamber test exporter

For manufacturers and suppliers, compliance with fire safety regulations is crucial. Various international standards, such as ASTM E662 (Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials), dictate the requirements for smoke density testing. By adhering to these standards, companies can ensure that their products meet the necessary safety criteria, ultimately protecting end-users and minimizing liability risks.

Furthermore, the smoke density chamber test provides valuable data that can inform design decisions. Engineers can select materials that not only fulfill structural requirements but also exhibit lower smoke density, contributing to overall safety in building and vehicle design. This proactive approach to fire safety can vastly improve occupant safety and reduce potential property damages in the case of an emergency.

Exporting Smoke Density Testing Expertise

As the global demand for safer materials grows, so does the need for expertise in smoke density testing. Manufacturers looking to export their products to international markets must ensure compliance with various national regulations regarding fire safety and smoke production. This requirement has spurred the growth of companies specializing in smoke density testing services, offering consultation, testing, and certification to help manufacturers navigate international compliance standards.

These exporters provide essential insights into the testing process, helping manufacturers understand the specific requirements needed to pass various smoke density tests. By leveraging their expertise, companies can enhance their marketability and acceptability in regions with strict fire safety laws.

Conclusion

The smoke density chamber test is an indispensable component of fire safety assessments for a wide range of materials. By providing a reliable method to measure smoke production, this test helps manufacturers comply with regulations and ensures that end users are safeguarded against fire hazards. As industries continue to prioritize safety, the importance of smoke density testing will only continue to rise. Exporters of smoke density testing services play a crucial role in this ecosystem, bridging the gap between product innovation and safety compliance on a global scale. By investing in smoke density testing, manufacturers can enhance their reputation, ensure safety, and contribute to a safer built environment for everyone.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy