Smoke Density Chamber Testing for Industrial Applications and Safety Assessments

Smoke Density Chamber Test An Essential Tool for Fire Safety Compliance

Smoke density chamber tests play a critical role in ensuring the safety of materials used in construction, transportation, and various other industries. These tests evaluate the smoke-producing characteristics of materials when exposed to fire, providing valuable data that informs safety standards and product regulations.

Smoke Density Chamber Test An Essential Tool for Fire Safety Compliance

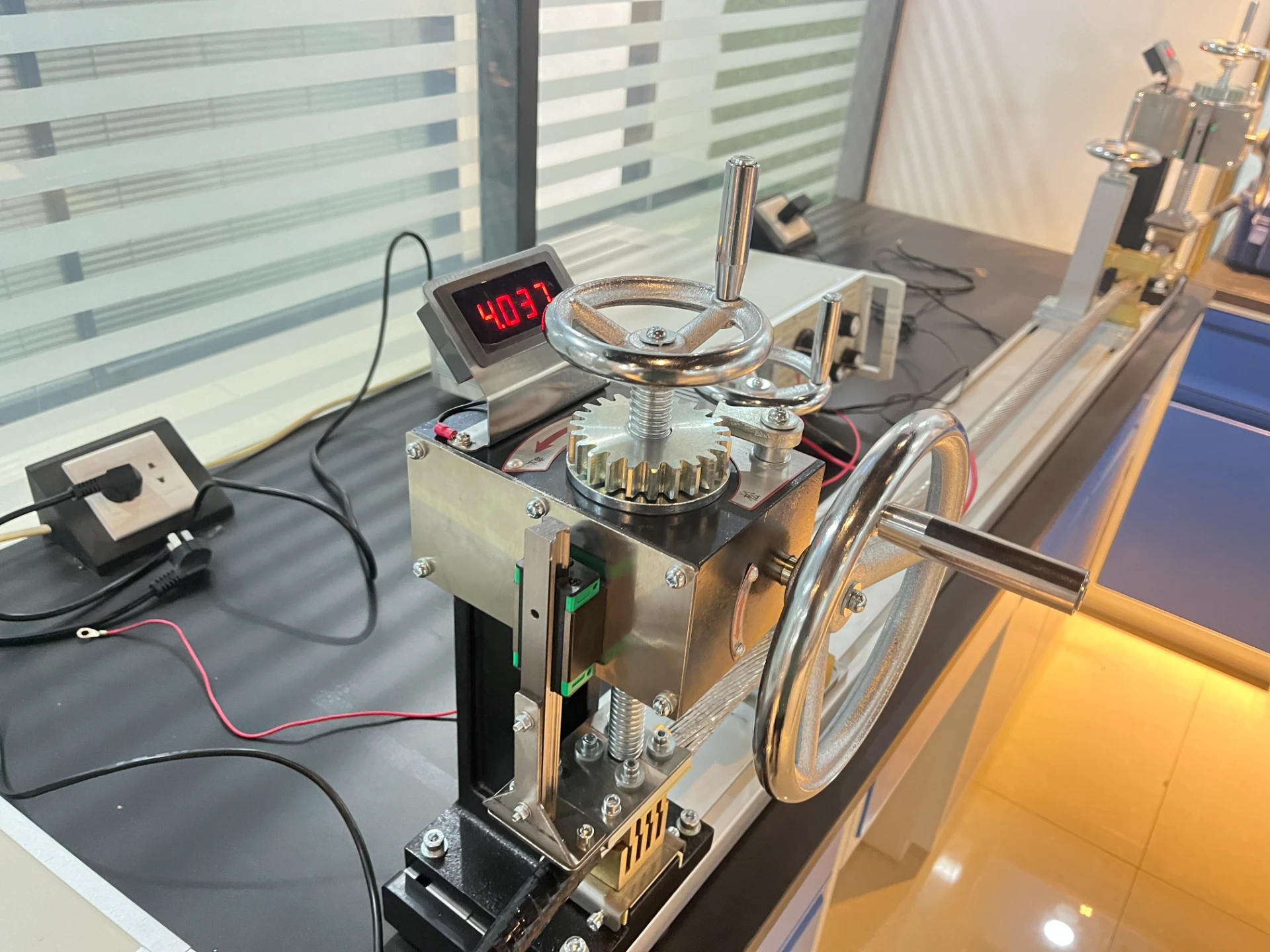

The smoke density chamber is a specialized testing facility designed to measure the amount of smoke produced by a material when it burns. In this controlled environment, samples are subjected to heat until they ignite, and the resulting smoke is collected and analyzed. The data gathered is quantified in terms of optical density, indicating the degree of opacity produced by the smoke. This measurement helps in assessing the risks associated with smoke inhalation and visibility during a fire.

smoke density chamber test factories

Factories that produce building materials, textiles, plastics, and other combustible products are particularly focused on obtaining positive results from smoke density tests. Regulatory bodies often have stringent requirements, and failure to meet these can not only result in fines but also damage a company’s reputation. As such, organizations are prioritizing compliance by investing in advanced testing facilities and adhering to international standards, such as those set by ASTM and ISO.

Moreover, with the increasing emphasis on sustainability, manufacturers are also exploring eco-friendly materials that generate less smoke or toxic byproducts. Innovations in formulation technologies are allowing for the development of products that maintain performance while improving their smoke density profiles.

In conclusion, smoke density chamber tests are a vital component in the broader spectrum of fire safety and compliance. By providing essential data on the smoke characteristics of materials, these tests not only protect public safety but also enhance product quality. As industries continue to evolve and adapt to stricter regulations and sustainability goals, the importance of such testing will only grow, ensuring that safety remains a foremost priority in all manufacturing processes.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy