Exporters of Smoke Density Test Equipment for Quality Assurance

The Importance of Smoke Density Testers A Focus on Exporters

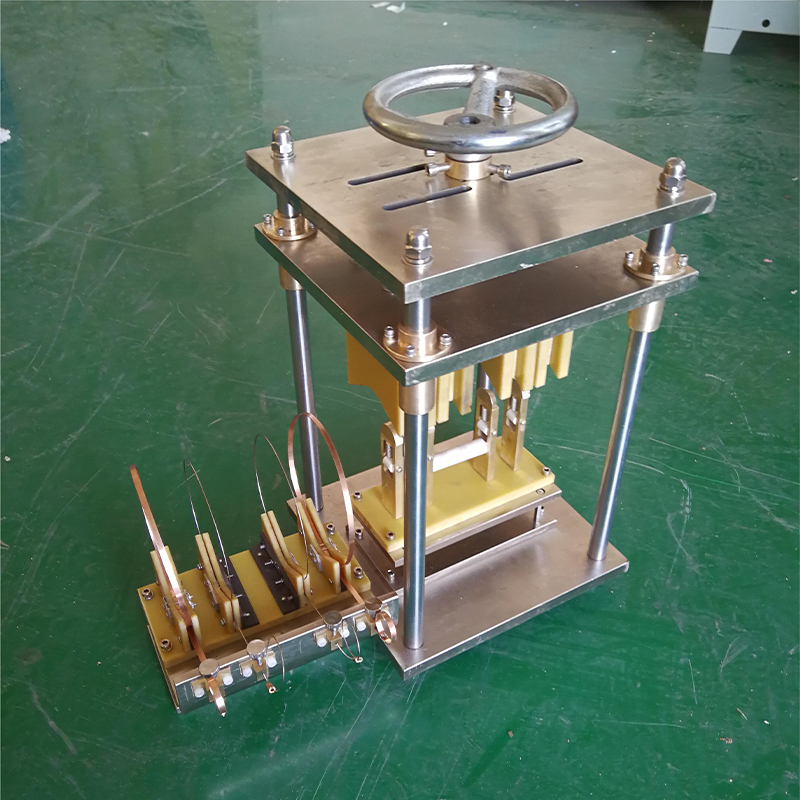

In recent years, the demand for smoke density testers has surged significantly, driven by the growing awareness of fire safety and the need for stringent quality control in various industries. Smoke density testers are essential instruments used to evaluate the smoke-producing characteristics of materials when they are exposed to fire. This article delves into the significance of smoke density testers, the role of exporters in the global market, and the key considerations surrounding their use.

Understanding Smoke Density Testing

Smoke density testing is critical in assessing the potential hazards posed by materials during combustion, particularly in construction, automotive, and aerospace industries. The primary goal is to measure the amount of smoke produced when a material is burned, as excessive smoke can obscure visibility and pose risks to safety during evacuations. The results of these tests help manufacturers comply with safety regulations and develop products that minimize smoke emissions, improving overall fire safety.

The smoke density tester operates by exposing a sample to a controlled flame and measuring the amount of smoke emitted. The results are quantified using various methods, such as the specific optical density of the smoke, which provides manufacturers with reliable data for further analysis and product development.

The Role of Exporters

As the demand for smoke density testers grows, so does the role of exporters in the market. Exporters are crucial in facilitating the distribution of these essential instruments across borders, enhancing accessibility for industries that require strict compliance with fire safety standards. They ensure that manufacturers, laboratories, and testing facilities have access to the latest technology and equipment.

Exporters often work with a diverse array of smoke density tester manufacturers, allowing them to offer a wide range of products tailored to specific industry needs. By providing guidance on the best solutions available, they help businesses choose the right equipment that aligns with their fire safety objectives.

Market Dynamics and Trends

The global market for smoke density testers has exhibited substantial growth, particularly in regions with strict fire safety regulations, such as North America, Europe, and parts of Asia. Increased investments in fire safety protocols, coupled with rising awareness of the implications of poor smoke performance, continue to propel demand for quality smoke density testing equipment.

smoke density tester exporters

Additionally, advancements in technology have led to the development of more sophisticated smoke density testers, integrating features such as remote monitoring and data analytics. Exporters play a vital role in ensuring that customers have access to these advanced devices, which enhance the testing process and improve accuracy.

Key Considerations for Choosing a Smoke Density Tester

When selecting a smoke density tester, several factors must be considered

1. Compliance Standards Ensure that the tester meets the necessary standards set by organizations such as ASTM, ISO, or NFPA. Compliance with these regulations guarantees that the test results are recognized and accepted globally.

2. Precision and Accuracy Look for testers that provide precise and accurate measurements of smoke density. High-quality instruments are invaluable for reliable data that informs safety measures.

3. Ease of Use User-friendly design and functionality help expedite testing processes. Training and support services provided by exporters can also enhance usability.

4. Maintenance and Support Consider the availability of maintenance services and technical support from the exporter to ensure the longevity and reliability of the equipment.

Conclusion

In conclusion, smoke density testers are indispensable tools for promoting fire safety across various industries. The role of exporters is crucial in distributing these devices globally, ensuring that manufacturers comply with safety standards and contribute to the protection of lives and properties. As the market continues to evolve, it is essential for businesses to stay informed about the latest advancements and best practices in smoke testing to maintain high safety standards and enhance the quality of their products. The continued collaboration between manufacturers, exporters, and end-users will drive the development of safer materials and ultimately create a more secure environment for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy