Smoke Density Testing Equipment Manufacturer for Reliable Performance and Quality Assurance

Smoke Density Tester Factory Ensuring Safety Through Innovation

In a world increasingly concerned with safety and environmental standards, the importance of effective smoke density testing cannot be overstated. Smoke density testers play a crucial role in ensuring that materials meet fire safety standards, contributing to the overall health and safety of public spaces, buildings, and products. This article will explore the significance of smoke density testers, the manufacturing processes involved, and the future of this essential equipment in fire safety.

Understanding Smoke Density Testing

Smoke density testing is a vital process used to measure the opacity of smoke produced by combustible materials when subjected to fire. The primary aim is to assess how dense or opaque the smoke is, which can significantly impact visibility and safe evacuation during a fire incident. Excessive smoke density can lead to confusion and panic while also posing serious health risks from inhalation. As such, various industries, including construction, automotive, and aerospace, require reliable smoke density testers to ensure the materials they use will not produce hazardous levels of smoke in the event of a fire.

The Role of Smoke Density Tester Factories

Smoke density testers are produced by specialized factories that focus on quality control, precision engineering, and adherence to safety regulations. These factories utilize advanced technologies and methodologies to create machinery that delivers accurate and reliable results. The manufacturing process typically involves the following steps

1. Research and Development Innovating new technologies and improving existing designs is essential to keep pace with evolving fire safety regulations and standards. Smoke density tester factories invest in research to ensure their products remain relevant and effective.

2. Material Selection The safety and durability of smoke density testers depend significantly on the materials used in their construction. Factories carefully select high-quality materials that can withstand rigorous testing conditions.

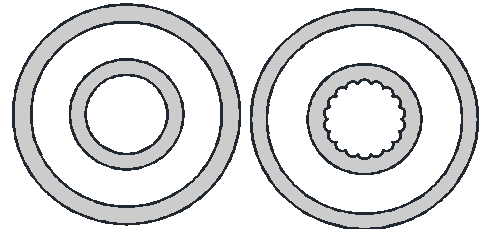

smoke density tester factory

3. Precision Engineering Crafting smoke density testers with precise measurements ensures that the results are accurate. Factories employ skilled engineers and technicians who understand the importance of each component and its contribution to the overall function of the tester.

4. Quality Assurance After production, each smoke density tester undergoes stringent quality checks to ensure compliance with international safety standards. This step is crucial for manufacturers to build trust with their clients and demonstrate reliability.

5. Calibration and Testing Before they reach the market, smoke density testers must be calibrated to ensure they provide accurate readings. This involves subjecting the testers to controlled conditions to validate their performance.

The Future of Smoke Density Testing

As global awareness of fire safety increases, the demand for advanced smoke density testers is expected to rise. Factories are adapting by incorporating smart technologies and digital interfaces, allowing for real-time monitoring and data analysis. This innovation not only enhances the ease of use but also improves overall safety measures.

Moreover, environmental concerns are pushing factories to develop eco-friendly testing methods and materials. The integration of sustainable practices in manufacturing processes will likely become a priority, ensuring that smoke density testers not only meet safety standards but also align with global sustainability efforts.

Conclusion

Smoke density tester factories are at the forefront of fire safety innovation, producing essential equipment that helps prevent disasters and protect lives. Through rigorous manufacturing processes, these factories ensure that their products meet high-quality standards while continuously adapting to new technologies and environmental concerns. As industries prioritize safety and sustainability, the role of smoke density testers and their manufacturers will only continue to grow in importance. The commitment to quality and innovation in smoke density testing is vital for creating a safer future for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy