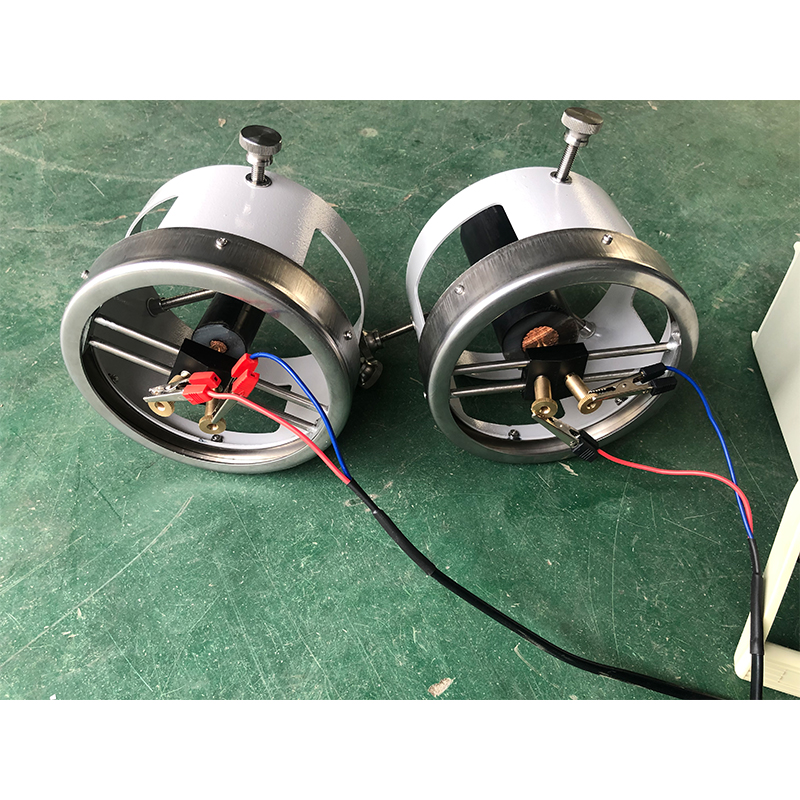

smoke density test machine exporter

The Importance of Smoke Density Test Machines in Fire Safety

In the context of fire safety, the assessment of materials' smoke density is crucial for evaluating their performance when exposed to fire. Smoke density test machines play a pivotal role in determining how much smoke a particular material will generate when subjected to burning or high temperatures. This evaluation is essential for industries that prioritize fire safety, such as construction, automotive, aerospace, and many more.

What is a Smoke Density Test Machine?

A smoke density test machine is a specialized apparatus designed to measure the amount of smoke produced by burning materials. It operates according to specific standards, such as ASTM E662 or ISO 5659, and typically involves burning a sample in a controlled environment while measuring the light obscuration caused by the smoke generated. The machine records this data, providing valuable insights into the smoke density and toxicity levels of the tested materials.

Applications of Smoke Density Test Machines

1. Building Materials Testing In the construction industry, the choice of materials can significantly impact safety during a fire incident. Smoke density test machines help manufacturers and builders ensure that the materials they use—such as insulation, roofing, and flooring—meet safety standards and regulations.

2. Automotive and Aerospace Industries In vehicles and airplanes, the reduction of smoke generation in the event of a fire can save lives. Smoke density test machines are used to assess and certify materials used in interiors, seat covers, and other components to minimize smoke-related hazards.

3. Electrical and Electronic Equipment For electrical appliances and electronics, the materials used can pose extra risks in case of overheating or fire. Evaluating the smoke density produced by components and casings ensures compliance with safety standards and reduces the risk of toxicity.

4. Toxicity Assessment Beyond just smoke density, many smoke density test machines can also assess the toxicity of the smoke produced. This characteristic is critical for ensuring that smoke inhalation does not pose life-threatening risks to individuals during a fire situation.

smoke density test machine exporter

Choosing the Right Smoke Density Test Machine

When sourcing smoke density test machines, exporters and manufacturers must consider several factors

- Compliance with Standards Ensure that the machine complies with international safety and testing standards. This compliance guarantees accuracy and reliability in the testing processes.

- Ease of Use Machines that provide user-friendly interfaces and easy operation protocols can enhance efficiency and minimize training time for operators.

- Data Reporting Look for machines that offer advanced data reporting functionalities. The ability to generate comprehensive reports facilitates better analysis and documentation for regulatory compliance.

- Durability and Maintenance Test machines are significant investments. Choose equipment built from durable materials and designed for easy maintenance to minimize long-term operational costs.

Conclusion

The role of smoke density test machines in promoting fire safety cannot be overstated. By accurately measuring the smoke emitted from materials during combustion, these machines help safeguard lives and properties across various industries. Exporters and manufacturers involved in the production and supply of these machines play a critical role in enhancing public safety and compliance with fire safety regulations.

As industries continue to evolve and innovate, the demand for reliable smoke density testing equipment will only grow. Companies that prioritize adopting modern, efficient, and accurate testing machinery will not only promote safety in their own operations but will also contribute to the larger goal of creating safer environments for everyone. Investing in high-quality smoke density test machines is not merely an operational choice; it is a commitment to prioritizing safety in an increasingly hazardous world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy