Evaluating Performance of Spark Test Environments in Manufacturing Factories

The Role of Spark Test Machines in Modern Factories

In the ever-evolving landscape of manufacturing, efficiency and precision stand as paramount qualities that determine the success of a factory. Among the many technological advancements that have transformed production lines, spark test machines have emerged as vital tools. These machines play a crucial role in ensuring product safety, quality, and reliability, thus contributing to the overall efficiency of factory operations.

Understanding Spark Test Machines

Spark test machines are specialized devices designed to examine the insulation integrity of electrical components and systems. These machines work by applying a high-voltage test signal to the insulation of a product to identify any electrical weaknesses or breakdowns. This process is essential in various industries, including automotive, electronics, and appliance manufacturing, where electrical safety is a paramount concern.

The operation of spark test machines typically involves generating a high-voltage spark that can traverse through unwanted paths in the insulation. If there is a fault, such as a pinhole or crack, a conductive path will allow a spark to jump through, indicating failure. The machine then provides critical feedback, enabling manufacturers to take corrective action before the products reach consumers.

Importance in Manufacturing

The integration of spark test machines into manufacturing processes significantly enhances product quality and safety. In industries where electrical safety is non-negotiable, these machines serve as an essential checkpoint in the production line. By identifying insulation defects early, manufacturers can prevent hazardous situations that could lead to product recalls, liability claims, or even catastrophic failures.

Moreover, spark test machines help maintain compliance with national and international safety standards. With strict regulations governing electrical appliances and components, manufacturers need to ensure their products meet these guidelines. Using spark test machines facilitates rigorous testing, which helps companies avoid fines and reputational damage due to non-compliance.

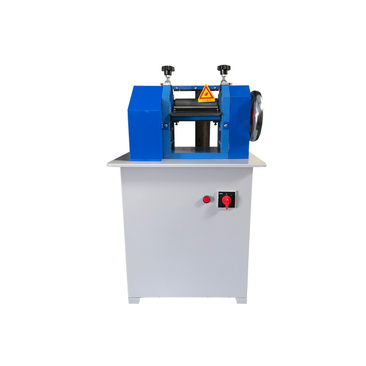

spark test machine factories

Advancements in Technology

Recent advancements in technology have significantly improved the functionality and efficiency of spark test machines. Modern machines come equipped with digital interfaces that provide real-time data, analytics, and reporting features. These enhancements allow engineers and quality control personnel to oversee testing procedures from a centralized location, streamline operations, and document results conveniently.

Additionally, advancements in automation have led to the development of fully automated spark testing systems. These machines can conduct tests at high speeds without human intervention, thus increasing throughput and reducing labor costs. Automation not only helps achieve consistency in testing but also minimizes the risk of human error, leading to more reliable results.

The Future of Spark Testing

As factories continue to embrace Industry 4.0 principles, the role of spark test machines is likely to evolve further. The integration of Internet of Things (IoT) technology into testing machinery allows for remote monitoring and predictive maintenance. By analyzing data collected during testing, manufacturers can anticipate potential insulation failures before they occur, thus optimizing maintenance schedules and reducing downtime.

Furthermore, as industries shift toward more sustainable practices, spark test machines can contribute to these efforts by ensuring that only high-quality, safe products are manufactured. This reduces waste generated from faulty products and enhances customer satisfaction, as consumers are more likely to trust products that undergo rigorous testing procedures.

Conclusion

In conclusion, spark test machines are indispensable tools in modern factories. They play a critical role in ensuring electrical safety, maintaining compliance with regulatory standards, and enhancing product quality. With ongoing advancements in technology and automation, these machines are set to become even more integral to manufacturing processes. As industries continue to innovate and improve, the importance of reliable testing solutions will only grow, making spark test machines a foundational element of efficient and safe manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy