Suppliers of Advanced Cable Torsion Testing Machines for Enhanced Quality Assurance in Manufacturing

Exploring Cable Torsion Testing Machines Suppliers and Their Significance

In the realm of material testing, the importance of cable torsion testing machines cannot be overstated. These machines are essential for assessing the performance and durability of cables, particularly in applications where they must withstand twisting and torsional forces. As industries continue to advance and evolve, the demand for high-quality cable torsion testing machines has surged, leading to a growing number of suppliers in the market.

Understanding Cable Torsion Testing

Cable torsion testing is a critical evaluation process designed to measure the ability of a cable to withstand twisting forces. This type of testing is crucial for applications in sectors such as telecommunications, aerospace, and construction, where cables are often subjected to dynamic loads and must maintain structural integrity under various conditions.

A cable torsion testing machine operates by applying controlled torsional loads to a cable specimen until it fails. This process helps determine the mechanical properties of the cable, including its torsional strength, stiffness, and elongation under strain. By understanding these characteristics, manufacturers can ensure that their cables meet industry standards and regulations while also optimizing performance for specific applications.

The Role of Suppliers

As the demand for these testing machines has grown, numerous suppliers have emerged, contributing to the landscape of cable torsion testing equipment. These suppliers play a vital role by providing high-performance machines that cater to diverse testing requirements. When choosing a supplier, there are several key factors to consider

1. Quality and Reliability A reputable supplier should offer machines that are built to last. High-quality components and reliable design are essential for accurate and consistent testing results.

2. Customization Options Different industries may require tailored solutions based on their specific testing needs. A good supplier should provide customization options, allowing customers to modify machine specifications to suit their unique requirements.

3. Technical Support and Service Excellent customer support is paramount. Suppliers that offer comprehensive technical assistance, maintenance services, and training programs help ensure that customers can effectively operate and manage their torsion testing machines.

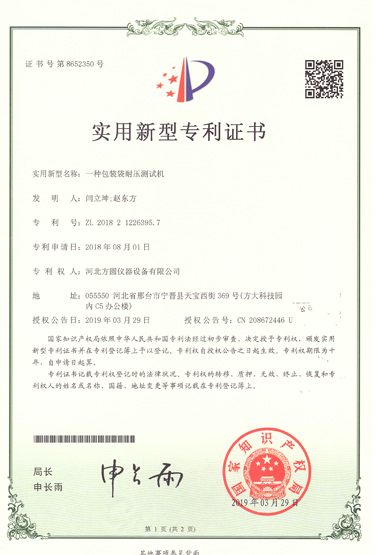

cable torsion testing machine suppliers

4. Innovative Technology The field of material testing is continuously evolving, with new technologies emerging to improve efficiency and accuracy. Suppliers that invest in research and development often provide cutting-edge machines that incorporate advanced features such as automated testing cycles, data logging, and real-time monitoring.

5. Certifications and Standards Compliance It is crucial that the machines provided by suppliers comply with international testing standards. Certification ensures that the testing process will yield results that are recognized across the industry.

Leading Suppliers in the Market

The market for cable torsion testing machines comprises various global suppliers, each with its unique strengths. Some notable names in the industry include

- Instron Known for its high-performance testing equipment, Instron offers a range of solutions tailored for cable testing. - ZwickRoell This company specializes in materials testing machines and provides advanced torsion testing instruments alongside a robust service network.

- MTS Systems MTS focuses on innovative materials testing technologies, offering customizable torsion testing solutions that help engineers meet specific standards.

- Shimadzu With a long-standing reputation for precision instrumentation, Shimadzu supplies reliable torsion testing equipment optimized for various materials.

Conclusion

Cable torsion testing machines play a critical role in ensuring the safety and reliability of cables used in numerous applications. With the increasing demand for high-quality testing solutions, the market has seen a rise in suppliers offering advanced machines tailored to the needs of diverse industries. By selecting a reputable supplier, companies can enhance their testing capabilities and ensure that their products meet the stringent standards required in today's competitive landscape. As technology advances, the role of these machines will only become more significant, driving innovation and safety across various sectors.

-

The Role of Tensile Force Testers in Quality Control and Material Science

NewsAug.01,2025

-

Maintenance and Safety Tips for Aging Ovens

NewsAug.01,2025

-

Density Balance in Forensic Science

NewsAug.01,2025

-

Advanced Optical Measurement Technologies

NewsAug.01,2025

-

A Buyer’s Guide to Tensile Test Machines

NewsAug.01,2025

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy