tensile strength of fabric tester manufacturers

Understanding Tensile Strength in Fabric Testing A Guide to Manufacturers

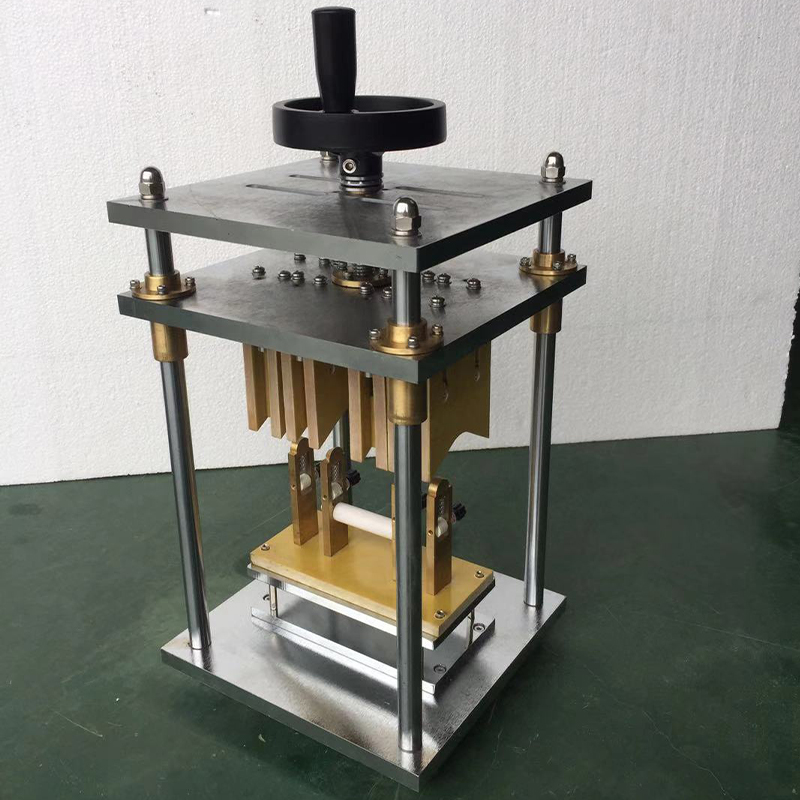

Tensile strength is a critical property in the textile industry, particularly in the context of fabric testing. It defines the maximum amount of tensile (pulling) stress that a material can withstand before failure. For manufacturers, understanding and measuring the tensile strength of fabrics is essential for ensuring product durability, quality, and safety. This article explores the importance of tensile strength testing, key manufacturers in the field, and the technologies they employ.

What is Tensile Strength?

Tensile strength reflects the resilience of a fabric under stretch and stress. It is measured in terms of force per unit area, often expressed in pounds per square inch (psi) or Newtons per millimeter squared (N/mm²). A fabric with high tensile strength can endure greater tension before tearing, making it suitable for various applications, from clothing to industrial use.

Testing tensile strength involves applying a controlled force to a fabric sample until it breaks. The results not only indicate the fabric's strength but also provide insights into its elasticity, tear resistance, and overall durability. This information is invaluable to manufacturers, as it guides material selection and product development.

Importance of Tensile Strength Testing

For manufacturers, tensile strength testing serves several crucial purposes

1. Quality Assurance Regular testing ensures that fabrics meet industry standards and specifications. This is particularly vital in sectors such as automotive, aerospace, and construction, where material failure can lead to severe consequences.

2. Material Selection By understanding tensile strength, manufacturers can select appropriate materials for specific applications. For instance, lighter fabrics may be preferred in athletic wear, whereas heavier, more robust textiles might be necessary for upholstery.

3. Product Development Knowledge of tensile strength aids in designing better products. Engineers and designers can create fabrics that not only meet aesthetic requirements but also perform under stress.

tensile strength of fabric tester manufacturers

4. Regulatory Compliance Many industries have stringent regulations regarding material properties. Continuous tensile strength testing helps manufacturers comply with these regulations, avoiding potential legal and financial repercussions.

Key Manufacturers in the Market

Several prominent manufacturers specialize in tensile strength testing equipment and technology. Some of the industry leaders include

- Instron Corporation A well-known name in materials testing, Instron offers a range of tensile strength testing machines, providing precise measurements and comprehensive data analysis. Their products are widely used in various industries, including textiles.

- MTS Systems Corporation MTS systems provide advanced solutions for testing the mechanical properties of materials, including textiles. Their equipment is recognized for its accuracy and reliability in demanding environments.

- Tinius Olsen Tinius Olsen develops innovative testing machines that measure various material properties, including tensile strength. Their user-friendly interfaces and robust designs make them a popular choice among manufacturers.

- ZwickRoell This company offers high-precision testing equipment for textiles and other materials. Their machines are known for their durability and accuracy, making them suitable for extensive testing tasks.

Conclusion

Tensile strength testing is a fundamental aspect of the fabric manufacturing process. Understanding the tensile properties of materials enables manufacturers to ensure quality, compliance, and performance in their products. With advancements in testing technology and the expertise of leading manufacturers, companies can access reliable solutions to meet the industry's evolving demands. As the textile market continues to grow and innovate, the need for accurate tensile strength testing will remain paramount, driving the industry toward higher standards and enhanced customer satisfaction.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy