Tensile Testing Machine Exporters for Quality Assurance in Material Strength Evaluation and Analysis

The Importance of Tensile Test Machines in Material Testing

Tensile test machines, also known as universal testing machines, play a crucial role in the field of material testing, particularly in determining the mechanical properties of materials. These machines are essential for industries that require high-quality assurance and adherence to safety standards, such as construction, automotive, aerospace, and manufacturing. The purpose of a tensile test is to measure how much a material can stretch or deform before it breaks, providing valuable insights into its strength, ductility, and overall performance.

Understanding Tensile Testing

Tensile testing involves elongating a material sample until it fractures while measuring the force applied and the corresponding elongation. The results yield critical data, including stress-strain curves, yield strength, ultimate tensile strength, elongation percentage, and reduction of area. This data not only helps in understanding the material's behavior under stress but also assists in quality control and material selection for specific applications.

Exporters of Tensile Test Machines

The global market for tensile test machines has been growing significantly, driven by the increasing demand for material testing across various sectors. Exporters of tensile test machines are at the forefront of this market, providing advanced technology and equipment that meet the varying needs of clients worldwide. These machines come equipped with sophisticated features, such as digital displays, automated controls, and data analysis software, which facilitate accurate and efficient testing.

Countries that are known for producing and exporting tensile test machines include Germany, the United States, Japan, and China. These nations have established themselves as leaders in mechanical engineering and manufacturing, promoting innovation and high-quality standards in their products. The machines are designed to comply with international testing standards, such as ASTM (American Society for Testing and Materials), ISO (International Organization for Standardization), and other regional regulations.

tensile tests machine exporters

Technological Advancements

Recent advancements in technology have led to the development of more efficient and user-friendly tensile test machines. Automation and digitalization have transformed traditional testing processes, making them faster and more reliable. For instance, modern tensile testers can now be integrated with software that enables real-time data analysis and remote monitoring, allowing engineers to gather insights even while working from different locations.

Moreover, the introduction of materials testing equipment with enhanced features, such as multi-function capabilities and higher load capacities, has expanded their applications. Manufacturers are now able to test not only metals but also polymers, composites, and other advanced materials, broadening the horizon for research and development.

Challenges Faced by Exporters

Despite the promising growth of the tensile test machine market, exporters face several challenges. Competition is fierce, with numerous manufacturers vying for market share. Additionally, ensuring compliance with various international standards and meeting the specific customization requests from clients can be hurdles for exporters. Moreover, supply chain disruptions and fluctuating raw material costs can impact production efficiency and profitability.

Conclusion

Tensile test machines are indispensable tools in the modern manufacturing and engineering landscape. As industries continue to prioritize quality and safety, the demand for reliable tensile testing equipment will only increase. Exporters who invest in innovative technologies, adhere to strict quality control measures, and respond effectively to market demands will be well-positioned to thrive in this competitive environment. Ultimately, the continued evolution of tensile testing machinery will enhance our understanding of materials and contribute to safer and more efficient designs in various applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

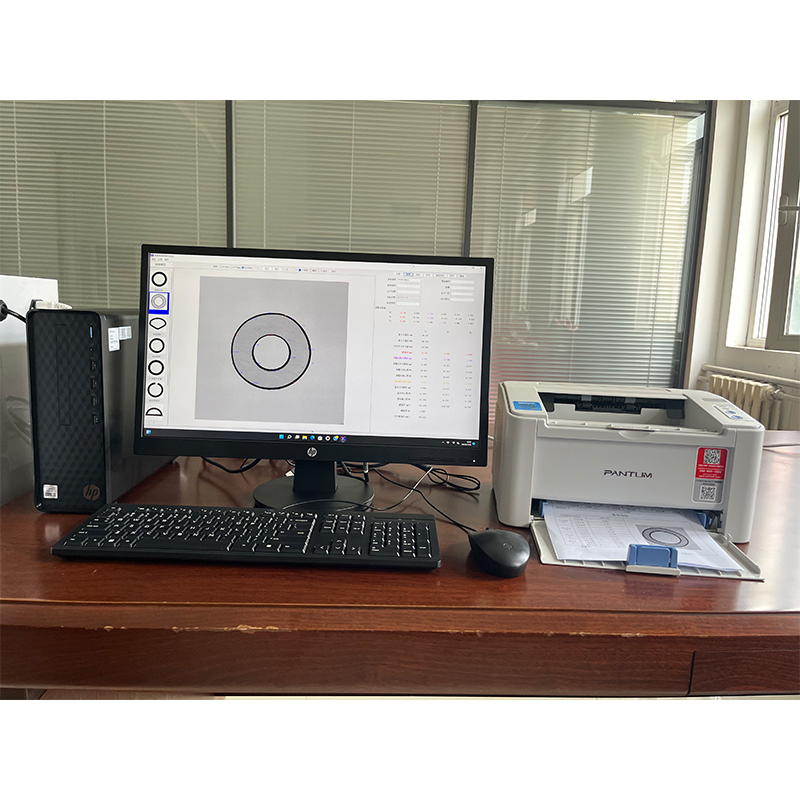

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy