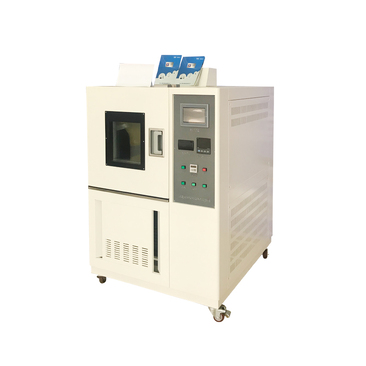

tensile force tester exporter

The Importance of Tensile Force Tester Exporters in Quality Control

In today's globalized market, the demand for high-quality materials and products is paramount, and one of the key players in ensuring that quality is maintained is the tensile force tester. These devices are essential for evaluating the mechanical properties of materials, such as their tensile strength and ductility. As industries across the spectrum — including construction, manufacturing, and textiles — continue to expand, the role of tensile force tester exporters becomes increasingly significant.

Tensile force testers are devices that measure the resistance of a material to being pulled apart. They provide invaluable data that help manufacturers to understand the limitations and capabilities of their materials, ensuring that products meet industry standards and regulations. By exporting tensile force testers to various sectors globally, companies facilitate better quality control processes, which ultimately leads to safer and more reliable products for consumers.

One of the primary attributes of high-quality tensile force testers is their precision. A well-manufactured tester provides accurate readings, which are crucial for developing materials that can withstand the stresses they will encounter in real-world applications. Exporters that specialize in this equipment often have a wealth of experience and technical expertise, ensuring that their products meet international standards such as ISO and ASTM. This expertise is vital for companies that may lack in-house capabilities for testing materials or who are looking to upgrade their existing testing methods.

tensile force tester exporter

Furthermore, tensile force tester exporters play a crucial role in supporting research and development (R&D) initiatives. As industries innovate and create new materials, the need for robust testing increases. Exporters can assist R&D departments by providing specialized equipment that caters to unique testing requirements, enabling companies to push the boundaries of what is possible in material science. This collaboration fosters innovation and helps businesses to stay competitive in a rapidly evolving market.

In terms of market dynamics, the exportation of tensile force testers contributes to the global supply chain. Countries that specialize in manufacturing high-quality testing equipment can benefit from increased trade opportunities. By exporting these testers, they not only stimulate their economies but also support international industries in achieving their quality standards. This interconnectedness highlights the vital role of tensile force tester exporters in the broader context of global manufacturing and quality assurance.

Moreover, with the rise of technology and automation, many tensile force testers now come equipped with advanced features such as digital displays, automated data logging, and software integration for comprehensive analysis. Exporters who keep pace with technological advances are better positioned to meet the evolving needs of their customers. Providing ongoing support, training, and updates on equipment usage is also critical, ensuring that clients can maximize the potential of their tensile force testers.

In conclusion, tensile force tester exporters serve as a cornerstone of quality control across various industries. Their ability to provide precision testing equipment not only bolsters manufacturing safety and reliability but also promotes innovation and global economic growth. As the demand for high-quality products continues, the importance of their role will only amplify, making them indispensable partners in the quest for excellence in material performance.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy