tensile force tester manufacturer

Understanding Tensile Force Tester Manufacturers

In the realm of material testing, tensile force testers play a pivotal role in assessing the strength and durability of various materials. From metals to plastics, the ability to analyze how materials respond to stress and strain is crucial for manufacturers and engineers alike. This article explores the significance of tensile force testers and highlights what to consider when selecting a manufacturer for these essential testing devices.

What is a Tensile Force Tester?

A tensile force tester, also known as a universal testing machine (UTM), is designed to apply axial load to a test specimen until it deforms or fractures. The device measures several key parameters, including tensile strength, yield strength, elongation, and reduction in area. These metrics provide invaluable insights into a material's performance and help ensure that products meet the required safety and quality standards.

Applications of Tensile Force Testers

Tensile force testers are widely utilized across various industries, including automotive, aerospace, construction, and plastics. In the automotive industry, for example, manufacturers use these testers to evaluate the materials used in vehicle parts, ensuring they can withstand forces encountered during operation. Similarly, the aerospace industry demands rigorous testing of materials to guarantee safety in flight operations. In the construction sector, tensile strength tests are crucial for evaluating concrete, steel, and other materials used in building scaffolds and structures.

The Importance of Choosing the Right Manufacturer

Selecting a reliable tensile force tester manufacturer is imperative for obtaining accurate and consistent results. Here are several factors to consider when making your choice

tensile force tester manufacturer

1. Quality and Precision The most reputable manufacturers prioritize precision and quality in their testing equipment. Look for manufacturers that adhere to international standards, such as ISO 9001, and have a track record of producing reliable machines.

2. Technical Support and Training A manufacturer that offers comprehensive technical support and training will be invaluable. Equipment users must not only understand how to operate the tester but also how to interpret the results. Ongoing support ensures that users can maximize the capabilities of the equipment.

3. Customization Options Different industries have unique requirements, and a one-size-fits-all approach may not be sufficient. The best manufacturers offer customizable tensile force testers tailored to specific applications, allowing businesses to achieve their testing goals effectively.

4. Software Integration Modern tensile force testers often come with advanced software that facilitates data analysis, storage, and reporting. Manufacturers that provide innovative software solutions can significantly enhance the efficiency of the testing process, enabling users to make data-driven decisions swiftly.

5. Reputation and Reviews Investigate the manufacturer’s reputation within the industry. Online reviews, case studies, and testimonials from other businesses can provide insights into a manufacturer’s reliability and the performance of their equipment.

6. After-Sales Service After purchasing a tensile force tester, ongoing support is critical. Look for manufacturers that offer maintenance, calibration services, and warranty options. This ensures that your investment remains reliable over the years.

Conclusion

The role of tensile force testers in material testing cannot be overstated. They provide essential data that influence the design, safety, and performance of products across various industries. When selecting a tensile force tester manufacturer, focus on quality, customization, technical support, and reputation. By doing so, you will ensure that your investment yields accurate results and enhances the overall reliability of your products. Whether you're a small-scale manufacturer or a large corporation, making the right choice in tensile force tester manufacturing will pave the way for success and innovation in your industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

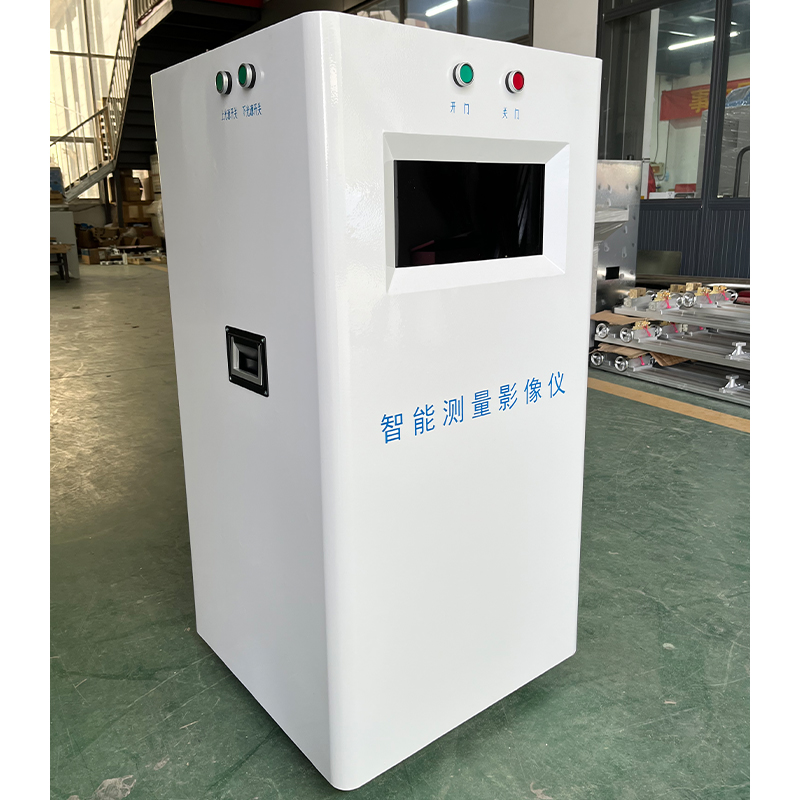

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy