Top Suppliers of Tensile Force Testing Equipment for Accurate Material Evaluation

Understanding Tensile Force Tester Suppliers

In the contemporary manufacturing and engineering landscape, quality assurance and material testing play pivotal roles in ensuring product performance and safety. Among the various testing instruments available, tensile force testers are indispensable for assessing the strength and durability of materials under tension. As industries increasingly recognize the importance of these devices, the demand for reliable tensile force tester suppliers has surged.

What is a Tensile Force Tester?

A tensile force tester, also known as a tensile testing machine or tensile testing apparatus, is designed to measure the tensile strength of materials. It assesses how materials behave when subjected to pulling forces, which is crucial in determining their mechanical properties, including yield strength, elongation, and reduction in area. These tests are vital in fields such as construction, manufacturing, textile, and aerospace, where material integrity is paramount.

The Role of Suppliers in the Industry

Tensile force tester suppliers are key players in the supply chain, providing high-quality testing equipment, accessories, and support services. Their role extends beyond simply selling machines; they educate clients on selecting the appropriate equipment based on specific needs, provide maintenance services, and often assist in the calibration of testing machines to ensure accurate results.

A reputable supplier typically offers a range of tensile force testing machines catering to different industries. This includes universal testing machines, which can perform a variety of tests, and specialized devices tailored to specific materials such as metals, plastics, and textiles. Some suppliers also provide software solutions for data analysis, ensuring that measurements are reported accurately and conveniently.

Key Considerations When Choosing a Supplier

When selecting a tensile force tester supplier, several factors should be taken into account

1. Product Range A supplier that offers a wide variety of models can better serve different testing needs. Some businesses may require high-capacity machines, while others might need portable testers for field applications.

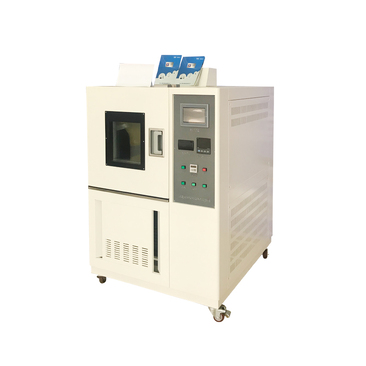

tensile force tester suppliers

2. Quality and Compliance It’s essential to choose a supplier whose equipment adheres to international standards, such as ISO or ASTM. Compliance ensures that the testing conducted is recognized and accepted globally, providing credibility to the results.

3. Technical Support and Service Quality suppliers will provide comprehensive after-sales support, including installation, calibration, maintenance, and repairs. This level of service can significantly reduce downtime and extend the life of the equipment.

4. Customer Reviews and Reputation Researching a supplier's reputation in the industry can provide insights into their reliability and quality of service. Reading customer reviews and testimonials can help potential buyers make informed decisions.

5. Pricing and Financing Options While cost is a crucial factor, it shouldn't be the sole determinant. Suppliers offering flexible financing options or leasing agreements can provide a better path to acquiring high-quality testing equipment without straining financial resources.

Innovations and Trends in Tensile Testing

The field of tensile testing is constantly evolving, with technological advancements leading to smarter, more efficient machines. Some of the trends include the integration of automation and robotics to enhance testing efficiency, the incorporation of advanced software for detailed data analysis, and the development of eco-friendly testing machines that reduce energy consumption.

Additionally, digital solutions are making it easier to share and analyze data, enabling companies to make quicker and more informed decisions regarding material specifications and quality control protocols.

Conclusion

The role of tensile force tester suppliers is more critical than ever in ensuring that materials meet the necessary standards for safety and performance. As industries continue to innovate and evolve, finding a reliable supplier becomes an essential task for businesses aiming to enhance their quality assurance processes. By considering key factors such as product range, quality, support, and reputation, companies can partner with suppliers that not only meet their immediate testing needs but also foster long-term growth and compliance in an increasingly competitive landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy