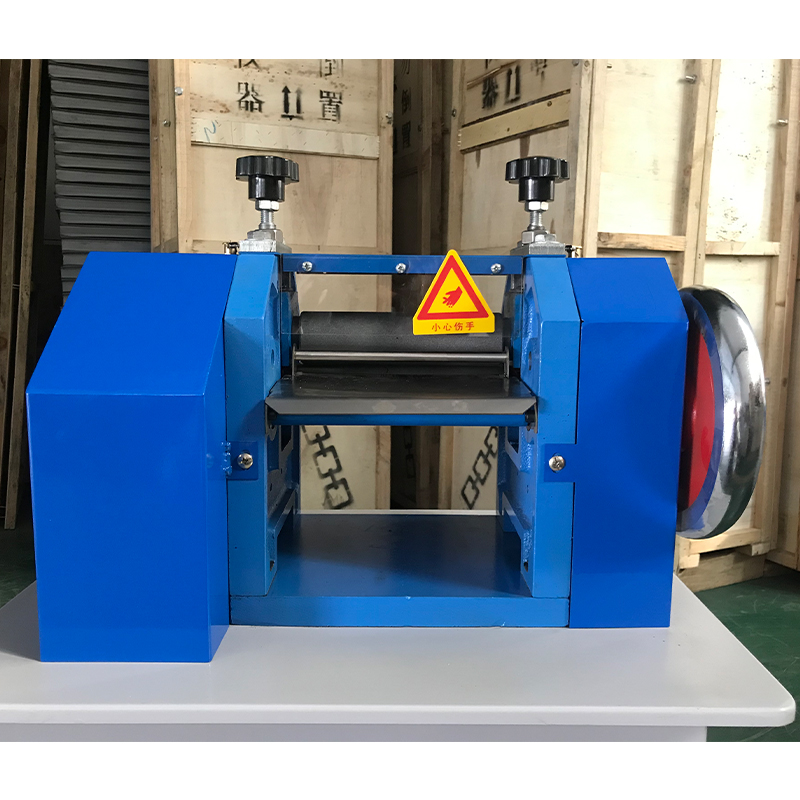

tensile force tester suppliers

Understanding the Importance of Tensile Force Tester Suppliers

In various industries, especially in manufacturing and materials testing, the tensile force tester plays a crucial role in determining the mechanical properties of materials. These devices measure the tensile strength, elongation, and other properties of materials under tension, which are vital for quality control, research and development, and ensuring safety standards are met. Given the significance of these testing instruments, finding reliable tensile force tester suppliers is essential.

What is a Tensile Force Tester?

A tensile force tester, also known as a tensile testing machine or equipment, is utilized to understand how materials behave under pulling or tensile forces. The test involves placing a material sample in the machine and gradually applying a tensile load until the sample breaks. During the test, various measurements are taken, such as the maximum load the material withstands (tensile strength) and the amount it can be stretched before breaking (elongation). The data collected helps engineers and researchers fine-tune the material properties for better performance in real-world applications.

The Role of Suppliers

Tensile force tester suppliers are integral to the production and maintenance of these machines. They provide not only the equipment itself but also essential services like installation, calibration, and after-sales support. Here are some key aspects that highlight the role of suppliers in this field

1. Diverse Product Offerings Leading manufacturers and suppliers of tensile force testers usually offer a range of products catering to different testing requirements. This diversity ensures that businesses can find a suitable machine based on their specific needs, whether they are testing metals, plastics, textiles, or composite materials.

2. Technological Advancements As technology evolves, so do the capabilities of tensile testing machines. Suppliers who stay ahead of the curve provide the latest models equipped with advanced features like digital displays, automated testing cycles, and data analysis software. This not only improves the accuracy of the tests but also enhances the user experience.

3. Technical Support and Training A reputable supplier doesn't just sell equipment; they also offer technical support and training to ensure that clients make the most of their machines. Proper training is crucial for operators to understand how to use the equipment safely and effectively, thereby producing reliable test results.

4. Calibrating Services Calibration of tensile testers is essential to ensure precision in testing. Over time, machines can drift out of calibration due to various factors, which can lead to inaccuracies in measurements. Leading suppliers offer calibration services to verify that the machines are functioning correctly and meeting industry standards.

tensile force tester suppliers

5. Customization Different sectors have unique requirements for tensile testing. Some suppliers offer customization options, allowing businesses to tailor the machinery to suit their specific needs or testing regimes. This can include modifications in capacity, testing speeds, or additional features.

Choosing the Right Supplier

Selecting the right tensile force tester supplier is paramount for any organization looking to invest in testing equipment. Here are some criteria to consider

- Reputation and Experience Look for suppliers with a solid reputation in the industry. Experience often equates to better customer service and a deeper understanding of technical requirements.

- Customer Reviews It is beneficial to read customer testimonials and reviews to gauge the reliability of the products and services offered by the supplier.

- Service and Support Ensure that the supplier provides adequate support, including training and maintenance services. A good after-sales service can save time and money in the long run.

- Compliance and Standards Verify that the testing equipment meets relevant industry standards and certifications, such as ASTM or ISO, to ensure that test results are universally accepted.

Conclusion

Tensile force testers are indispensable tools in multiple industries, and choosing the right supplier can significantly impact testing accuracy and operational efficiency. As businesses continue to prioritize quality and performance, the demand for reliable tensile force tester suppliers will remain strong. By understanding the importance of these suppliers and what they offer, organizations can make informed decisions that enhance their testing capabilities and ultimately lead to better product quality and safety.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy