tensile strength of fabric tester exporters

Understanding Tensile Strength in Fabric Testing and the Role of Exporters

Tensile strength is a critical property of fabrics that determines their durability, usability, and overall performance in various applications. In the textile industry, the ability of a material to withstand tension without breaking is essential, making tensile strength testing a fundamental process. This article explores the significance of tensile strength testing, the equipment involved, and the role of exporters in the global market.

The Importance of Tensile Strength Testing

Tensile strength testing assesses how much stretching or pulling a fabric can endure before failing. This measurement is important for several reasons. Firstly, it helps manufacturers select suitable materials for specific applications, ensuring safety and functionality in products such as clothing, upholstery, and industrial fabrics. High tensile strength is crucial for items that undergo significant stress, such as parachutes, safety harnesses, and outdoor gear.

Moreover, tensile strength impacts the longevity and cost-effectiveness of products. Fabrics with higher tensile strength tend to last longer, thus reducing the need for frequent replacements and minimizing waste, which aligns with the increasing demand for sustainable practices in the textile industry.

The Process of Testing

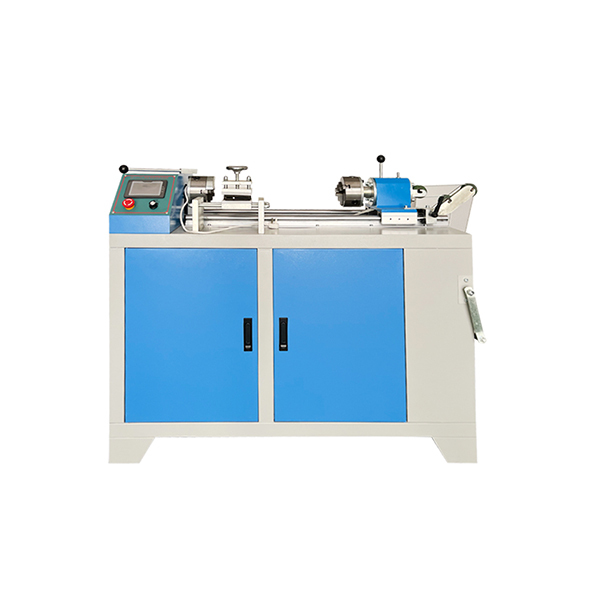

The process of tensile strength testing typically involves the use of specialized equipment such as universal testing machines (UTMs). These machines apply a controlled force to a fabric sample until it ruptures, measuring the amount of force applied and the elongation of the fabric. The results are expressed in terms of stress (force per unit area) and strain (deformation relative to the original length), providing valuable data on the fabric's performance characteristics.

tensile strength of fabric tester exporters

Different testing standards might be employed, such as ISO, ASTM, or BS standards, which ensure consistency and reliability in results. These standards often dictate the dimensions of the fabric samples, the rate of loading, and the environmental conditions under which the tests are conducted.

Exporters in the Global Fabric Market

The global demand for high-quality fabrics has led to a robust market for textile exporters specializing in materials with verifiable tensile strength properties. Exporters play a vital role in connecting manufacturers with suppliers who provide not only raw fabric but also the necessary testing equipment and expertise.

These exporters have a deep understanding of various markets and customer needs, enabling them to source fabrics that meet specific criteria, including tensile strength ratings. By leveraging international supply chains, exporters can offer a wide range of materials, from high-performance technical fabrics to everyday textiles, catering to diverse industries such as fashion, automotive, and aerospace.

Furthermore, reliable exporters ensure compliance with international standards, providing certification and test results that enhance buyer confidence. In a competitive global market, transparency regarding tensile strength and other fabric properties can significantly influence purchasing decisions.

Conclusion

In conclusion, tensile strength testing is an essential component of fabric quality assessment, influencing product safety and longevity. The role of exporters in this context cannot be understated, as they facilitate the movement of high-quality fabrics across borders while ensuring compliance with testing standards. As the textile industry continues to evolve, the collaboration between manufacturers, testers, and exporters will remain crucial in meeting the growing demands of consumers and industries alike. Through their efforts, the industry can promote sustainable practices, improve fabric performance, and ultimately contribute to a more resilient global market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy