Tensile Strength Measurement Solutions for Fabric Testing Equipment Providers

Understanding Tensile Strength Testing in Fabric Supply

Tensile strength testing is a critical aspect of fabric quality assessment that ensures materials meet specific performance criteria. This kind of testing evaluates the maximum amount of stress a fabric can withstand while being stretched or pulled before breaking. For suppliers in the textile industry, understanding tensile strength and its implications play a significant role in maintaining quality assurance and meeting client expectations.

Importance of Tensile Strength

Tensile strength is fundamental in determining how a fabric will perform during its intended usage. Whether the fabric is destined for clothing, upholstery, or industrial applications, its strength will directly influence its durability, longevity, and overall wear performance. Fabrics with high tensile strength are less likely to tear or deform under stress, making them ideal for critical applications where reliability is paramount.

For instance, in apparel manufacturing, tensile strength contributes to the fit and comfort of garments. Fabrics that can withstand greater forces without stretching excessively maintain their shape, providing a better fit and reducing the likelihood of garment failure. In industrial applications, such as seatbelts and protective gear, the need for high tensile strength is essential for safety. Therefore, suppliers must prioritize sourcing and testing materials with appropriate tensile strength to ensure their products meet industry standards and consumer expectations.

The Testing Process

Fabric suppliers typically utilize various methods to test tensile strength, including strip testing and grab testing. In strip testing, a sample of fabric is cut into a specific size and subjected to tensile forces until it breaks. This method evaluates the fabric's strength along its length. Grab testing, on the other hand, involves holding the fabric in grips and pulling it until it fails. This method is more representative of how fabrics behave in real-world applications, as it simulates the forces exerted on garments or textiles during wear.

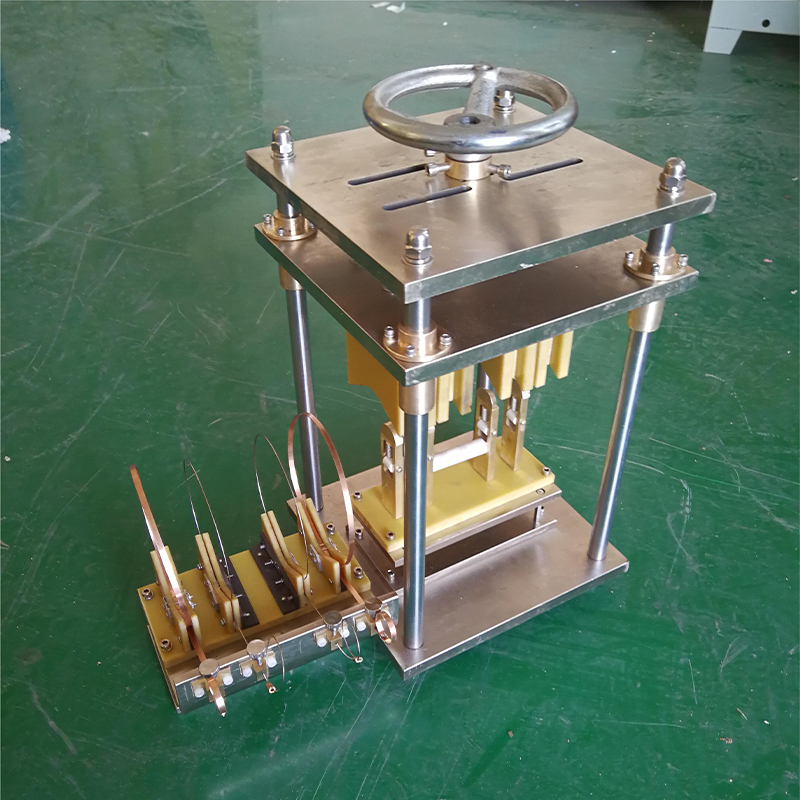

tensile strength of fabric tester supplier

The results from these tests provide suppliers with critical data that not only speak to the quality of their products but also guide them in the selection of materials for specific applications. Testing results are often documented and shared with clients, reinforcing the supplier’s commitment to quality and transparency.

Choosing the Right Supplier

When sourcing fabrics, it’s essential to collaborate with suppliers who not only understand the fabric-testing process but also possess the necessary equipment and expertise to conduct it effectively. Suppliers with a robust quality assurance program and access to advanced testing technologies can offer more reliable and reproducible results.

Additionally, a supplier's ability to provide detailed testing reports can serve as a competitive advantage. These reports not only help in meeting regulatory compliance but can also be a selling point for manufacturers looking to assure consumers of the durability and quality of their products.

Conclusion

In the fast-evolving textile industry, the importance of tensile strength testing cannot be overstated. For fabric suppliers, investing in thorough testing processes and maintaining high standards of quality assurance can lead to improved customer satisfaction and loyalty. By ensuring that the fabrics they supply have the necessary tensile strength, they can guarantee that end-users receive products that meet their performance needs, ultimately contributing to the success of their clients' offerings in the market. Thus, as the demand for robust and high-quality fabrics continues to rise, suppliers that prioritize tensile strength testing will undoubtedly find themselves at a competitive advantage.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy