tensile strength of fabric tester supplier

Understanding Tensile Strength Testing for Fabrics A Guide for Industry Professionals

In the textile industry, the integrity and durability of fabric materials are paramount. Among the numerous characteristics that determine a fabric's performance, tensile strength is one of the most critical. It measures how much pulling force a fabric can withstand before it breaks. This parameter is essential for manufacturers, designers, and quality control professionals looking to ensure that their products meet the required performance standards. Consequently, selecting a reliable tensile strength testing machine is crucial for any fabric supplier or manufacturer.

What is Tensile Strength?

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can endure before failure. In the context of fabrics, this means how much weight or tension a piece of textile can handle before it rips or tears. This measurement is typically represented in units such as pounds per inch (lb/in) or kilopascals (kPa), and it varies based on the fiber type, weave, and finishing processes involved in fabric production.

Importance of Tensile Strength Testing

1. Quality Assurance For fabric suppliers, maintaining high-quality standards is essential. Regular tensile strength testing helps to ensure that products are consistent and perform as expected, thus reducing the risk of failures in the final application.

2. Material Selection Designers and manufacturers use tensile strength data to choose appropriate materials for specific applications. For instance, fabrics used in outdoor gear must possess higher tensile strength compared to those used in garments.

3. Compliance Standards Various industries have regulatory standards that fabrics must meet. Tensile strength testing ensures compliance with these standards, safeguarding the manufacturer against potential liability and ensuring consumer safety.

4. Performance Evaluation In performance-oriented industries, such as sportswear, tensile strength testing allows manufacturers to evaluate how well a fabric will perform under stress, which is critical for products that undergo rigorous use.

Choosing a Tensile Strength Tester

When selecting a tensile strength tester, several factors should be considered to ensure that the equipment meets specific testing needs

1. Testing Method There are various methods for measuring tensile strength, including grab tests, strip tests, and tongue tests. Understanding the testing standards relevant to your industry will guide your choice.

tensile strength of fabric tester supplier

2. Load Capacity Ensure that the tensile tester you choose can handle the materials you'll be testing. Different fabrics exhibit varying tensile properties, and the machine must be capable of measuring them all accurately.

3. User-Friendliness Consider machines that provide user-friendly interfaces and efficient data management systems. This is especially important for labs that will have multiple operators utilizing the equipment.

4. Calibration and Accuracy Regular calibration is essential to maintain the accuracy of test results. Choose equipment that offers reliable calibration options and a reputation for precision.

5. Supplier Reputation Partnering with a reputable supplier of tensile strength testers can result in better customer support, machine reliability, and potential training for staff on best practices.

Features of Modern Tensile Strength Testers

Today's tensile strength testers come equipped with advanced features that enhance testing capabilities

1. Digital Display Innovations in technology provide digital readouts for easier interpretation of results. 2. Automated Systems Automated testing systems can reduce human error and enhance throughput, allowing for more efficient quality control processes.

3. Data Logging Modern testers often feature built-in data logging capabilities, enabling users to keep accurate records of test results over time for traceability and quality audits.

4. Comparative Analysis Some machines can compare results against predetermined thresholds or previously recorded data, which aids in immediate quality assessments.

Conclusion

In summary, understanding the tensile strength of fabrics is vital for ensuring the reliability and quality of textile products. By investing in appropriate testing equipment from reputable suppliers, fabric manufacturers and suppliers can enhance their product offerings while meeting industry standards. As the textile industry continues to evolve, so too does the technology for testing and measuring fabric properties, making it essential for industry professionals to stay informed about the latest advancements. By prioritizing tensile strength testing, stakeholders not only protect their brands but also contribute to the broader pursuit of quality and innovation in textiles.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

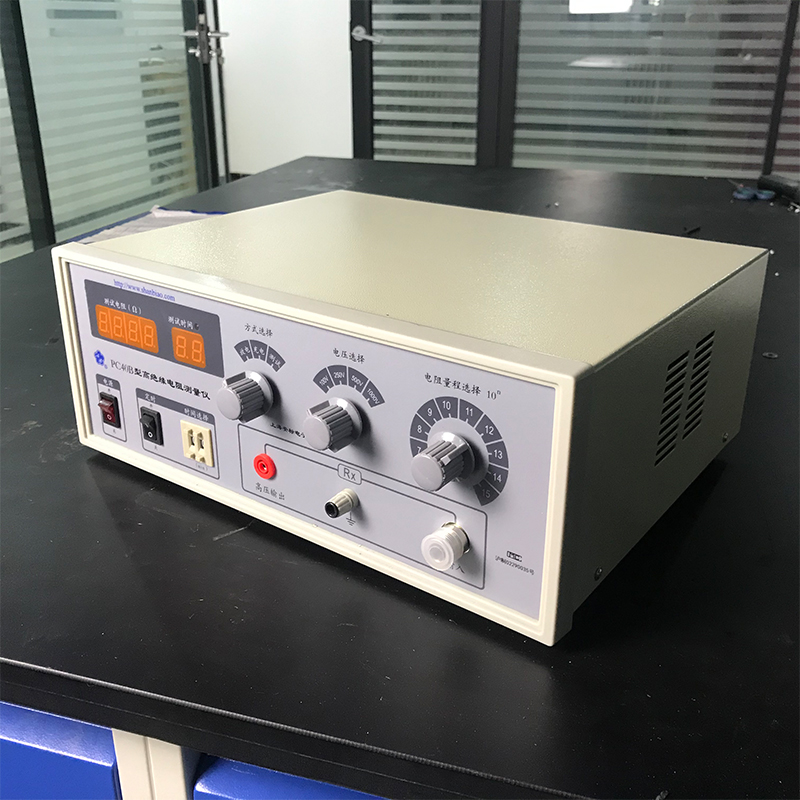

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy