tensile strength tester machine company

Understanding Tensile Strength Tester Machines A Key to Material Integrity

In the realm of material testing, tensile strength is one of the most critical parameters used to determine the durability and reliability of various substances. Tensile strength tester machines, therefore, play an indispensable role in industries ranging from construction to aerospace, ensuring materials meet necessary standards and specifications. This article delves into the significance, operation, and advancements of tensile strength tester machines, while highlighting key companies in this field.

What is Tensile Strength?

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. Understanding this property is crucial for manufacturers and engineers, as it influences design choices and material selection for applications ranging from bridges to consumer products. Tensile strength testing allows companies to predict how materials will behave under stress, which is essential for safety and performance.

The Role of Tensile Strength Tester Machines

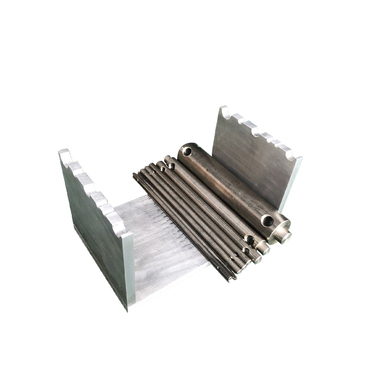

Tensile strength tester machines are specialized equipment designed to measure the tensile strength and other mechanical properties of materials. Typically, these machines apply a controlled amount of force to a sample until it fails, allowing operators to gather data on how the material behaves under tension. The test results provide valuable insights into properties such as tensile strength, yield strength, elongation, and reduction in area.

These machines often consist of several key components, including

1. Grips Securely hold the material sample. 2. Load Cell Measures the force being applied to the sample. 3. Crosshead Moves at a controlled speed to apply tension. 4. Data Acquisition System Collects and analyzes data during the test.

The Testing Process

The process of using a tensile strength tester typically follows a standardized protocol. A sample of the material is prepared, often shaped into a specific form to ensure accurate results. The sample is then placed in the machine's grips, and the test begins. As tension is applied, the machine records data regarding force and elongation until the material yields or fractures.

The outcome of the test is essential for quality control, research and development, and compliance with industry standards. It assists companies in making informed decisions about material usage, ensuring safety, and enhancing product performance.

Leading Companies in Tensile Strength Testing Machines

tensile strength tester machine company

Numerous companies specialize in the production of tensile strength tester machines, each offering unique technologies and capabilities. Some of the leading manufacturers in this sector include

1. Instron Known for their high-quality testing equipment, Instron has been a leader in materials testing for decades. Their machines are renowned for reliability and precision.

2. MTS Systems Corporation MTS offers a wide range of testing equipment, including advanced tensile testing systems that cater to various applications.

3. ZwickRoell This company provides cutting-edge solutions for testing materials with a focus on customer needs and industry standards.

4. Shimadzu Corporation With a focus on innovation, Shimadzu produces state-of-the-art tensile testing machines integrated with sophisticated software for data analysis.

5. Tinius Olsen Tinius Olsen specializes in materials testing machines, offering versatile tensile testers suited for different industries.

The Future of Tensile Strength Testing

As industries continue to evolve, the demand for more sophisticated tensile strength testing machines is on the rise. Advances in technology, such as automation, data analytics, and machine learning, are transforming the testing landscape. These innovations allow for faster, more accurate results, enabling companies to keep pace with the growing demand for high-performance materials.

Moreover, the emphasis on sustainability and eco-friendly materials in manufacturing is prompting further research into alternative materials, making the role of tensile strength testing even more critical. This ensures that new materials meet the necessary safety and efficacy standards before they are deployed in real-world applications.

Conclusion

Tensile strength tester machines are essential tools in ensuring the integrity of materials across various industries. By providing critical data on material properties, these machines not only support quality assurance but also drive innovation in product development. As technology advances, the future of tensile strength testing looks bright, with endless possibilities for enhancing the reliability and sustainability of materials used in everyday life.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy