Suppliers of Tensile Strength Testing Equipment for Quality Assurance in Materials

Choosing the Right Tensile Strength Tester Machine Suppliers

When it comes to testing materials, especially in industries like construction, manufacturing, and textiles, a tensile strength tester is an indispensable tool. This piece of equipment measures the force required to pull a material until it breaks, providing vital data on the material's strength and elasticity. With the growing demand for such testing machines, there are numerous suppliers in the market. Choosing the right tensile strength tester machine supplier can vastly influence the quality of your testing and, subsequently, your product's performance in the field.

Importance of Quality in Testing Machines

High-quality tensile strength testers are crucial for ensuring accurate results. Poorly designed or manufactured machines may deliver inconsistent data, leading to incorrect assessment of material properties. This, in turn, could result in catastrophic failures in applications where material integrity is critical. Therefore, when searching for suppliers, it is imperative to prioritize quality. Look for suppliers that comply with international standards, such as ISO, ASTM, and other industry-specific certifications. This guarantees that the testing machines meet strict quality and reliability criteria.

Comprehensive Product Range

Different industries may require different specifications for tensile strength testers. Some may need more advanced features such as data logging, software integration, or higher load capacities. Suppliers that offer a comprehensive range of products can cater to various needs. They may provide machines designed for specific materials like metals, plastics, textiles, or composites. A supplier with a diverse product range allows you to find a solution that best fits your specific application.

Technical Support and Service

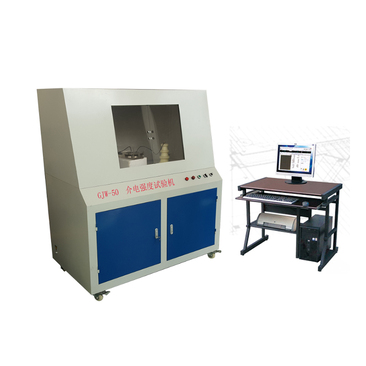

tensile strength tester machine suppliers

Another essential factor to consider when choosing a tensile strength tester machine supplier is the level of technical support and after-sales service they provide. Testing machines require regular calibration and maintenance for optimal performance. A supplier that offers robust customer support can ensure that any issues you encounter can be resolved quickly. This includes offering training for your staff on how to operate the machines safely and effectively. Additionally, inquire about the availability of spare parts and the average turnaround time for any repairs needed.

Customer Reviews and Reputation

Researching customer reviews and feedback is a valuable tool when evaluating potential suppliers. Satisfied customers are often a sign of reliability and quality. Look for testimonials that highlight the quality of the machines, the supplier’s responsiveness, and the effectiveness of their after-sales support. Suppliers that have established a positive reputation in the industry are typically more reliable, as they have consistently demonstrated their commitment to quality and customer satisfaction.

Pricing and Value for Money

While pricing should not be the only deciding factor, it is essential to evaluate the costs involved. Obtain quotes from multiple suppliers to determine the market rate for the type of tensile strength tester you require. Remember that the cheapest option may not always provide the best value for money. Consider the long-term benefits of investing in high-quality machines, which may reduce the overall operational costs through reliability and reduced downtime.

Conclusion

Selecting the right tensile strength tester machine supplier is vital for any organization involved in material testing. By prioritizing quality, product range, technical support, customer feedback, and pricing, you can make a well-informed decision. Investing time into this process can ensure that your materials meet safety and performance standards, ultimately leading to better products and a stronger market position. With the right supplier, your tensile strength testing can be a seamless part of your quality assurance process.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy