Leading Manufacturers of Tensile Strength Testing Equipment for Reliable Material Analysis

Tensile Strength Tester Manufacturers A Crucial Ingredient in Material Testing

In the realm of material science, the significance of tensile strength cannot be overstated. Tensile strength is the maximum amount of tensile (stretching) stress that a material can withstand before failure. Understanding this property is essential for a wide variety of industries, including construction, manufacturing, and aerospace. This is where tensile strength tester manufacturers come into play, providing vital equipment that ensures materials meet specific strength requirements.

The Role of Tensile Strength Testers

Tensile strength testers are specialized machines designed to analyze the mechanical properties of materials by applying stress until they break. During a tensile test, a sample piece is pulled in opposite directions, and various parameters such as the elongation, yield strength, and ultimate tensile strength are measured. The data collected from these tests helps engineers and quality control personnel assess whether a material is suitable for its intended application.

Industries Benefitting from Tensile Strength Testing

1. Construction Building materials such as steel and concrete must possess specific tensile strength properties to ensure the safety and longevity of structures. Manufacturers of construction materials often rely on tensile strength testers to validate their products before they reach the market.

2. Aerospace In the aerospace industry, the integrity of materials is paramount. Components must endure extreme conditions, including high stress and temperature variations. Tensile strength testing ensures that materials used in aircraft and spacecraft can withstand these challenges.

3. Automotive The automotive industry employs tensile strength testing for components such as metals, plastics, and composites to meet safety standards. Materials must be strong yet lightweight to improve fuel efficiency without compromising safety.

4. Textiles Textile manufacturers utilize tensile strength testers to evaluate the durability of fabrics. Whether for clothing, upholstery, or industrial applications, the strength of the materials used is crucial to performance and longevity.

Choosing a Tensile Strength Tester Manufacturer

tensile strength tester manufacturer

When it comes to selecting a tensile strength tester manufacturer, several factors should be considered

1. Quality and Accuracy The precision of testing equipment is fundamental. A reputable manufacturer should provide reliable machines that deliver accurate and repeatable results, ensuring that materials are tested consistently.

2. Technological Advancements As technology evolves, so do testing machines. Look for manufacturers that incorporate modern technology, such as digital interfaces, automated systems, and software integration, which can enhance testing efficiency and data analysis.

3. Support and Services A good manufacturer will not only sell the equipment but also offer comprehensive support services, including installation, calibration, and maintenance. Training for personnel who will operate the machines is also essential.

4. Customization Every industry has unique testing requirements. A manufacturer that offers customizable solutions can help businesses meet their specific needs, whether it’s adapting to different materials or accommodating various testing standards.

The Future of Tensile Strength Testing

As industries continue to innovate, the demand for advanced tensile strength testing will grow. The integration of artificial intelligence and machine learning is expected to revolutionize the way tensile tests are performed and interpreted. These technologies could lead to faster testing times, improved data analysis, and predictive maintenance for testing machines.

Furthermore, the increasing emphasis on sustainable materials will drive the need for rigorous testing to ensure that new material composites can meet performance criteria while remaining environmentally friendly.

Conclusion

Tensile strength tester manufacturers play a pivotal role in establishing the reliability and safety of materials across various industries. By investing in high-quality testing equipment, businesses can ensure that their products not only meet strict industry standards but also excel in performance. As technology advances, the future of tensile strength testing looks promising, paving the way for safer and more efficient materials in our increasingly complex world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

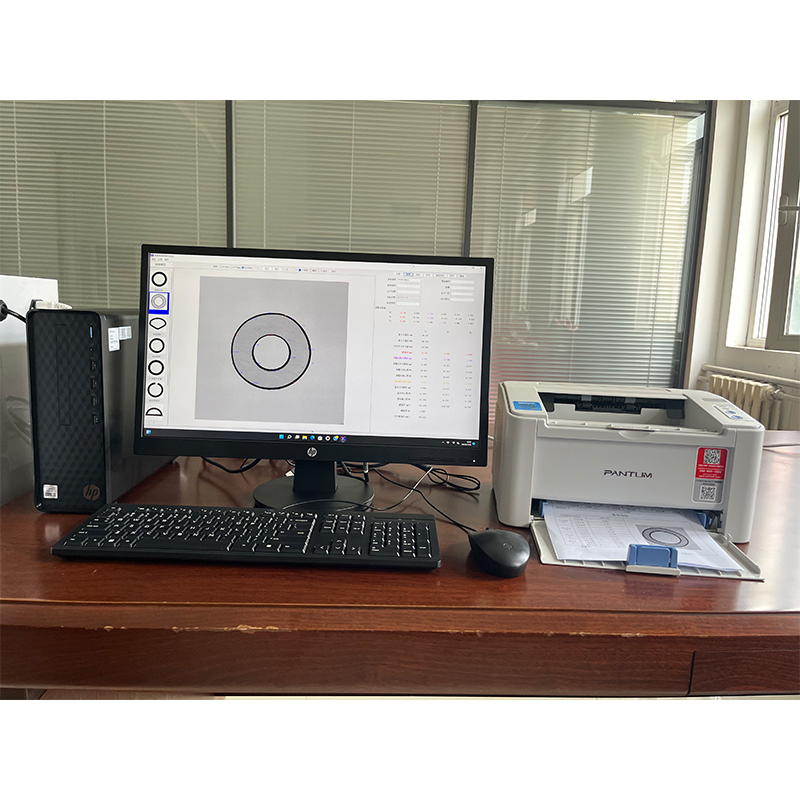

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy