tensile strength tester manufacturers exporter

Understanding the Role of Tensile Strength Tester Manufacturers in Global Exports

In the realm of material science and quality control, tensile strength testers play a pivotal role by providing critical data that helps manufacturers assess the durability and strength of materials. As global demand for high-quality materials continues to rise, the role of tensile strength tester manufacturers, especially those involved in exporting, has become increasingly significant. This article explores the importance of these manufacturers and the factors that contribute to their success in the international market.

The Importance of Tensile Strength Testing

Tensile strength refers to the maximum amount of tensile (stretching) stress that a material can withstand before failure. This property is crucial for various industries, including construction, automotive, aerospace, and manufacturing. The ability to accurately measure and analyze tensile strength is vital for ensuring that materials meet safety standards and perform adequately under stress.

Tensile strength testers are essential tools used in laboratories and manufacturing facilities to gauge the mechanical properties of materials. These machines perform tests that involve pulling a sample until it breaks and recording the amount of force applied. The data obtained helps engineers and quality control teams make informed decisions regarding material selection and product design.

Role of Manufacturers and Exporters

Manufacturers of tensile strength testers are tasked with designing and producing reliable equipment that meets international standards. Many of these manufacturers have embraced the global market, positioning themselves as exporters of tensile strength testing equipment. This has expanded their reach and allowed them to cater to diverse industries worldwide.

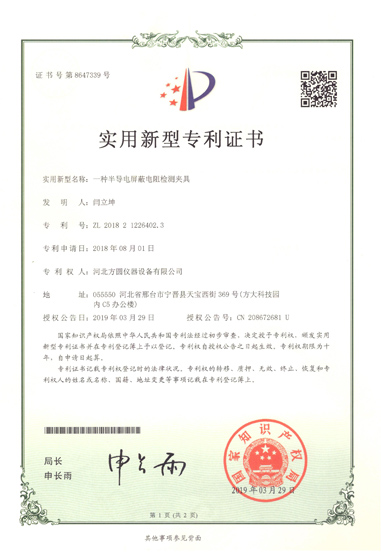

A successful exporter must ensure that their products comply with various regulatory requirements and meet the specifications demanded by international clients. This often involves obtaining certifications that assure customers of the product's quality and reliability. Furthermore, manufacturers must stay abreast of advancements in technology to improve the precision and efficiency of their testing equipment, thereby maintaining a competitive edge.

tensile strength tester manufacturers exporter

Key Factors for Success

1. Innovation in Technology The material testing industry is rapidly evolving with the advent of new technologies. Manufacturers that invest in research and development to innovate their products tend to excel in the global marketplace. Automation, software integration, and improved data analysis capabilities are just a few areas where innovation can enhance the functionality of tensile strength testers.

2. Quality Assurance To succeed as an exporter, manufacturers need to prioritize quality assurance throughout the production process. Implementing stringent testing protocols and quality control measures ensures that each unit meets the highest standards before it reaches international clients.

3. Global Networking Building strong relationships with overseas distributors and clients is crucial for manufacturers looking to export their equipment. Active participation in international trade fairs and industry conferences can facilitate networking opportunities and foster collaborations with potential clients.

4. Customer Support and Service Providing exceptional customer service post-sale can significantly enhance a manufacturer’s reputation. Offering training programs, maintenance services, and technical support keeps clients satisfied and fosters long-term relationships.

5. Sustainability As industries increasingly aim for sustainable practices, manufacturers that incorporate eco-friendly practices in their production processes can attract more clients. Utilizing sustainable materials and minimizing waste not only helps the environment but also serves as a strong selling point in the global market.

Conclusion

In summary, tensile strength tester manufacturers that prioritize innovation, quality, customer service, and sustainability are well-positioned to thrive in the global export market. As industries continue to rely on precise and reliable material testing, the significance of these manufacturers will only grow. Their contributions not only aid in ensuring product safety and reliability but also support the global push for high-quality materials in various sectors. As such, they play an indispensable role in the broader landscape of manufacturing and quality control.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy