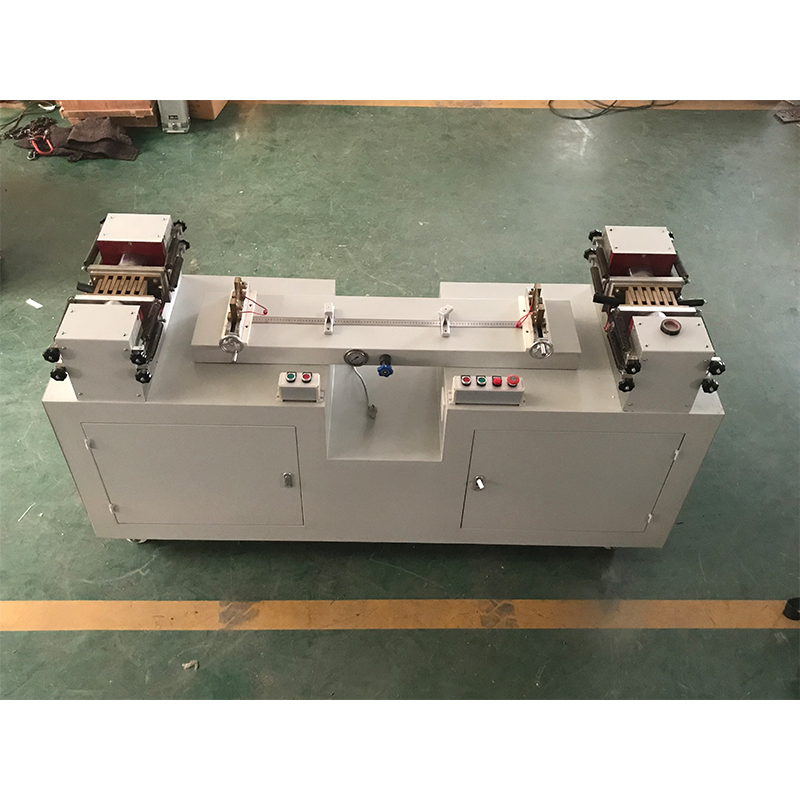

tensile strength tester supplier

Choosing the Right Tensile Strength Tester Supplier

When it comes to material testing, determining the tensile strength of materials is crucial across various industries. Whether in construction, manufacturing, or research, understanding how materials respond to stress and strain can make a significant difference in product quality, safety, and reliability. As such, selecting the right tensile strength tester supplier is a vital decision for any organization involved in material evaluation. This article aims to guide you through important considerations when searching for a reliable supplier of tensile strength testers.

Understanding Tensile Strength Testing

Tensile strength testing measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. It provides essential data about a material's strength, ductility, and other mechanical properties. Typically, these tests involve stretching a sample to its breaking point while recording the amount of force applied and the resulting elongation. The results are often used to inform design decisions, quality control processes, and compliance with industry standards.

The Importance of Choosing the Right Supplier

1. Quality of Equipment The foremost priority when selecting a tensile strength tester supplier is the quality of the equipment. It is essential to choose a supplier that provides reliable, accurate, and durable testing machines. High-quality equipment not only improves testing accuracy but also ensures longevity and reduces the need for frequent maintenance or replacements.

2. Range of Products Different materials, such as metals, plastics, textiles, and composites, require specific testing setups. A good supplier should offer a range of tensile strength testers suitable for various applications. This might include options for universal testing machines, high-capacity testers for heavy materials, or specialized devices for soft materials.

3. Compliance and Standards Testing equipment must comply with national and international standards (e.g., ASTM, ISO). Make sure the supplier's products meet these standards to ensure that your testing results are valid and widely accepted. This compliance is particularly important if your business operates in regulated industries, such as aerospace or automotive.

tensile strength tester supplier

4. Technical Support and Training An often-overlooked aspect of selecting a supplier is the level of support offered. Technical assistance in setting up the equipment, troubleshooting issues, or understanding testing protocols can significantly enhance operational efficiency. Consider suppliers that provide training sessions for your staff to ensure they are well-versed in using the equipment effectively.

5. Reputation and Reviews Before making a purchase, research the supplier's reputation within the industry. Online reviews, testimonials, and case studies can provide insights into their reliability, customer service, and the performance of their machinery. Additionally, consider reaching out to other professionals in your network to gather personal recommendations.

6. Customization Options Depending on your specific testing needs, you may require customized solutions. A supplier that offers tailored machinery and configurations can be invaluable, especially if your testing requirements are unique or evolving. Look for suppliers that can work closely with you to develop a solution that fits your needs.

7. Pricing and Warranty While cost shouldn't be the only factor in your decision, it's essential to find a supplier that offers competitive pricing without compromising quality. Additionally, inquire about warranties and post-purchase support. This can provide peace of mind, knowing that your investment is protected against manufacturing defects or early failures.

8. After-Sales Service The relationship with a supplier doesn't end after the purchase. A reliable supplier will provide ongoing support, including maintenance services, software updates, and calibration assistance. Ensure that they offer robust after-sales service to keep your equipment running efficiently.

Conclusion

Choosing the right tensile strength tester supplier is a critical step in ensuring that your material testing processes are effective and reliable. By considering aspects such as equipment quality, range of products, compliance with standards, technical support, reputation, customization options, pricing, and after-sales service, you can make an informed decision that aligns with your organization’s needs. The right supplier will not only provide you with the necessary tools to conduct accurate tensile strength testing but will also contribute to the overall success and safety of your operations.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy