Tensile Strength Testing Tools for Material Durability Assessment and Quality Control

Tensile Strength Testing Equipment A Critical Component in Material Testing

Tensile strength testing is a fundamental examination in materials science, helping engineers and scientists understand how materials behave under tension. It provides insights into a material's mechanical properties, which are crucial for a wide range of applications, from construction to aerospace. At the heart of this testing process lies tensile strength testing equipment, which plays a crucial role in determining the performance and reliability of materials.

Understanding Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling or stretching) stress that a material can withstand before failure. This property is essential for materials that will be subjected to stretching forces during their service life. The tensile strength tests reveal the material's yield strength, ultimate tensile strength, and elongation percentage, providing a comprehensive overview of its mechanical performance.

Types of Tensile Testing Equipment

There are various types of equipment used for tensile strength testing, including

1. Universal Testing Machines (UTMs) These are the most common machines used for tensile testing. UTMs can perform various tests, such as tensile, compression, and bending. They come with advanced software that allows for easy data collection and analysis, providing precise measurements of stress-strain curves.

2. Electromechanical Testing Machines These machines employ servomechanisms to control the loading process accurately. They are known for their precision and are suitable for testing materials that require strict adherence to testing protocols.

3. Hydraulic Testing Machines Utilizing hydraulic power, these machines can exert a large amount of force on a specimen. They are particularly effective for testing materials with high strength, such as metals and composites.

4. Static and Dynamic Testers While static testers evaluate materials under fixed loads, dynamic testers assess materials under fluctuating loads. Each type serves different testing needs, ensuring a comprehensive understanding of material behavior.

Key Features of Tensile Strength Testing Equipment

tensile strength testing equipment

When selecting tensile strength testing equipment, several features should be considered

- Load Capacity The maximum weight the machine can handle is crucial for testing different materials. Selecting a machine with an appropriate load capacity ensures accurate results and prevents equipment damage.

- Accuracy and Calibration The precision of measurements and the ability to calibrate the machine over time are vital for ensuring that results are reliable and consistent.

- Software Integration Modern tensile testing machines often come with software solutions that facilitate seamless data acquisition, analysis, and reporting. This integration helps in generating stress-strain curves and other relevant data efficiently.

- Ease of Use User-friendly interfaces and accessibility of controls are essential, especially in a production environment where multiple operators may use the same equipment.

Importance of Tensile Strength Testing

Tensile strength testing is indispensable across various industries. In construction, understanding the tensile strength of steel and concrete determines the safety and longevity of structures. In the automotive sector, materials must withstand high stresses and strains during operation, making tensile testing crucial for ensuring vehicle safety. The aerospace industry relies on lightweight yet strong materials to improve fuel efficiency and performance, necessitating rigorous tensile strength testing.

Moreover, tensile testing is vital for quality control purposes. Manufacturers can ascertain that their materials meet specific standards and specifications, reducing the risk of failure in final products. By understanding the tensile properties of materials, companies can also innovate and improve their products, leading to better performance and greater customer satisfaction.

Conclusion

Tensile strength testing equipment is a critical aspect of material testing that underpins numerous industrial applications. As technology advances, the machines become more sophisticated, allowing for greater precision and efficiency in testing. This essential process ensures that materials not only meet safety standards but also perform optimally in their intended applications. With tensile strength testing, industries can confidently produce reliable products that stand the test of time.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

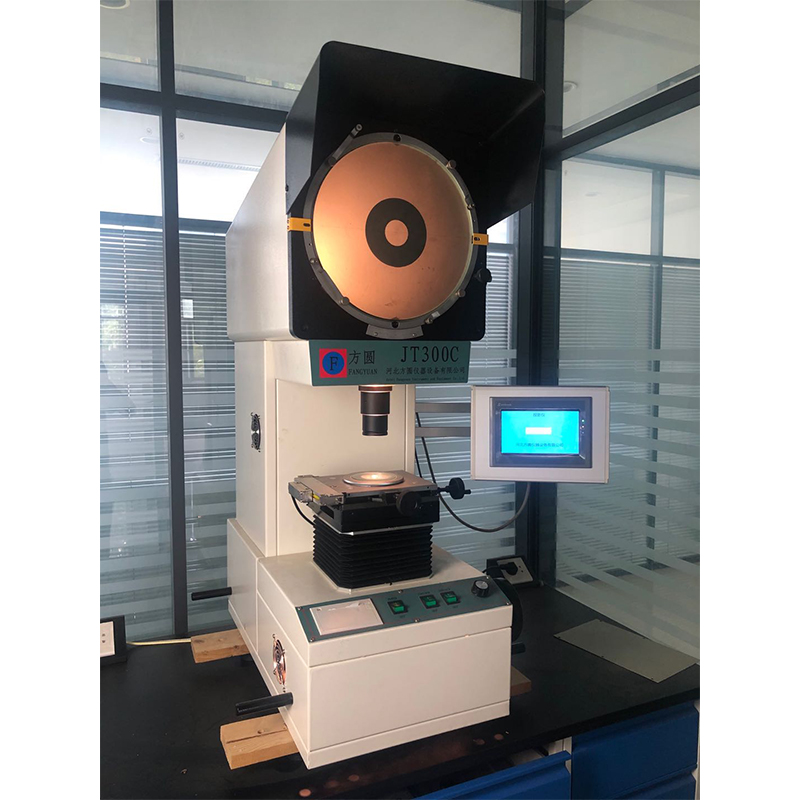

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy