tensile strength testing equipment factory

Tensile Strength Testing Equipment An Insight into the Factory Operations

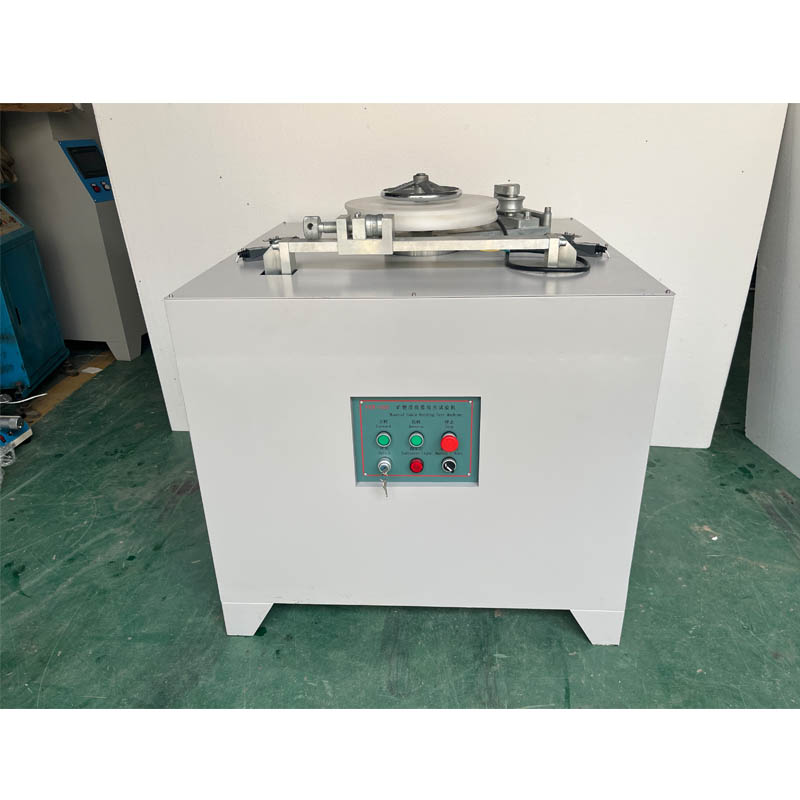

Tensile strength testing is a fundamental procedure in materials science, engineering, and manufacturing. It helps in determining how materials will perform under tension and is crucial for ensuring product reliability and safety. The equipment used for tensile strength testing is advanced, specialized, and critical in various industries such as construction, textiles, metals, and polymers. Understanding the operations within a tensile strength testing equipment factory can provide insights into the intricate processes behind this essential technology.

At the heart of any tensile strength testing equipment factory is a commitment to quality and precision. The production process typically begins with the design phase, where engineers and product designers collaborate to create equipment that meets specific testing standards, such as ASTM, ISO, or EN. These standards dictate how tensile tests are conducted and what specifications the equipment must meet, ensuring that the results are consistent and reliable.

Once the design is approved, the factory moves into manufacturing. This phase includes sourcing high-quality raw materials, such as steel and aluminum, which are critical to the durability and functionality of the testing machines. The materials undergo rigorous quality checks to ensure they meet the required standards before proceeding to machining. Employing precision machinery, skilled technicians cut, shape, and assemble the components of the testing equipment. Each unit is crafted with attention to detail, as even the slightest imperfection could affect the accuracy of the test results.

After assembly, the tensile strength testing machines are subjected to a series of quality control tests. These tests include calibration procedures to ensure that the equipment delivers precise measurements. Sophisticated sensors and data acquisition systems are integrated into the machines, allowing for accurate tracking of data during testing. A well-calibrated machine ensures that tensile strength values, along with elongation and yield strength, are recorded effectively, which is essential for manufacturers and researchers alike.

tensile strength testing equipment factory

Another critical aspect of the factory operations is the development of software that governs the tensile strength testing equipment. Modern machines often come equipped with advanced software that not only controls the testing process but also analyzes and reports the data. Engineers and software developers work hand-in-hand to create user-friendly interfaces that allow operators to customize testing parameters, ensuring comprehensive analysis. Moreover, data storage and tracking features are incorporated, facilitating easy access to historical data for ongoing research and compliance purposes.

Training is an integral part of the factory’s operations. Technicians and operators must understand how to use the machinery properly to avoid errors during testing. Factories often conduct regular training sessions, ensuring that personnel are up to date with the latest techniques and safety protocols. Additionally, manufacturers must provide clear guidance and documentation on operating the equipment, contributing to safe and efficient testing environments.

Furthermore, customer engagement is vital for a successful tensile strength testing equipment factory. Manufacturers typically maintain ongoing communication with their clients to understand their needs and to offer solutions that meet specific testing requirements. This feedback loop allows factories to innovate continuously and to develop new features or models that cater to emerging industries or advancements in material science.

In conclusion, the operations of a tensile strength testing equipment factory involve a sophisticated interplay of design, manufacturing, quality control, software development, training, and customer engagement. The dedication to quality and precision underscores the importance of these machines in ensuring that materials can withstand the stresses they will encounter in various applications. As technology advances, these factories will likely evolve, incorporating more automated solutions and innovative designs, thereby enhancing the capabilities of tensile strength testing and contributing to the safety and reliability of countless products in our daily lives.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy