tensile tester astm d412

Understanding Tensile Testing ASTM D412

Tensile testing is a fundamental procedure in material science and engineering that serves to assess the mechanical properties of various materials, particularly elastomers, plastics, and other rubber-like substances. Among the various testing standards available, ASTM D412 is one of the most influential; it specifies the procedures for tensile testing of rubber materials within the industry. This article delves into the significance, procedure, and implications of conducting tensile tests according to ASTM D412.

Significance of ASTM D412

ASTM D412 provides a standardized method for evaluating the tensile properties of rubber and elastomeric materials. These properties include essential measures like ultimate tensile strength, elongation at break, and modulus of elasticity. This testing is crucial for manufacturers and engineers as it helps determine how materials will behave under stress, which is vital for applications ranging from automotive components to medical devices.

By adhering to ASTM D412, companies can ensure consistent quality and performance in their products. For instance, in the automotive industry, rubber components must endure repeated stress and strains, which requires rigorous testing to ensure safety and reliability. Thus, this standardized method serves a dual purpose it safeguards consumers and enhances the reputation of manufacturers.

The Testing Procedure

The ASTM D412 testing procedure consists of several key steps

1. Sample Preparation Specimens must be prepared according to the specified dimensions and shapes defined in the ASTM D412 standard. Typical samples include dumbbell-shaped specimens, which are designed to ensure uniform stress distribution during the test.

2. Conditioning Before testing, it is essential to condition the rubber samples under specified temperature and humidity conditions. This step ensures that the material properties are not influenced by environmental factors that could affect the test results.

tensile tester astm d412

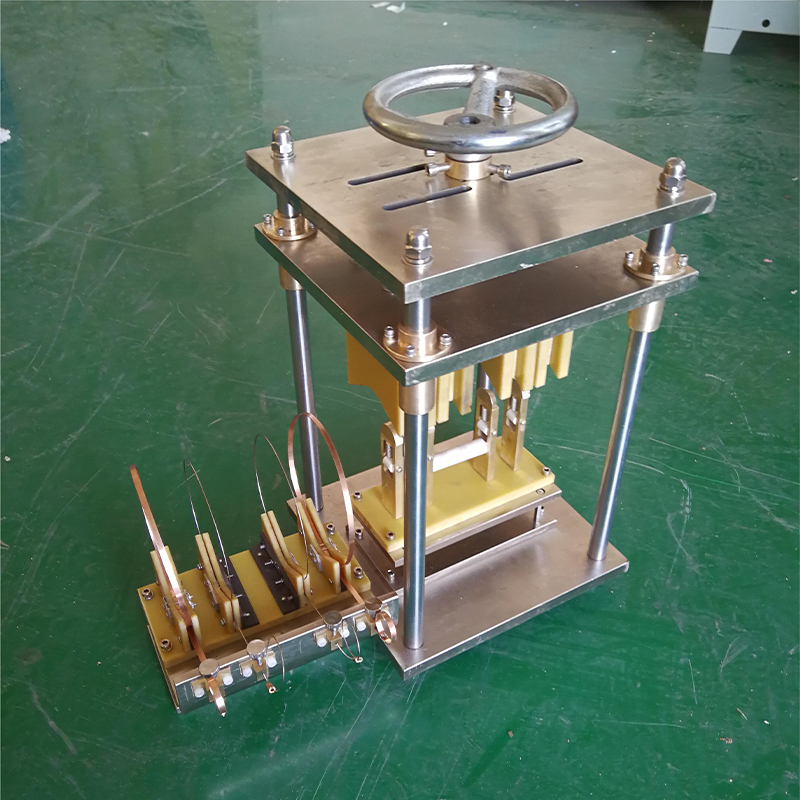

3. Testing Equipment Setup The tensile test is performed using a universal testing machine (UTM) equipped with extensometers that accurately measure the elongation of the material as it is subjected to tensile stress. The setup must be calibrated and validated to ensure accuracy and repeatability.

4. Conducting the Test The sample is clamped securely in the testing machine, and tension is applied until the material breaks. During the test, the machine measures the force applied and the corresponding elongation of the specimen, producing a stress-strain curve that illustrates the material's response to the applied force.

5. Data Analysis After the test, various data points are analyzed, including the maximum stress (tensile strength), the strain (elongation), and the modulus of elasticity. These results are critical for evaluating the material’s behavior in real-world applications.

Implications of Test Results

The results obtained from tensile testing according to ASTM D412 provide vital insights into the mechanical behaviors of rubber and elastomeric materials. Specifically, the tensile strength indicates the maximum stress the material can withstand before failure, while elongation at break reflects how much a material can stretch without breaking.

These parameters are essential for quality control and material selection in engineering applications. For example, a material with high tensile strength but low elongation may be suitable for applications requiring rigidity. Conversely, materials exhibiting high elongation are beneficial in applications where flexibility is crucial.

Furthermore, the consistency of test results as mandated by ASTM D412 contributes to regulatory compliance in various industries. Manufacturers can confidently market their products, knowing that they meet specific performance standards, thus minimizing the risks associated with material failure.

Conclusion

Tensile testing based on ASTM D412 is a pivotal process in assessing the mechanical properties of rubber and elastomeric materials. By following this standardized methodology, industries can ensure the safety, reliability, and performance of their products. As technology advances and new materials are developed, adherence to standards like ASTM D412 remains critical in fostering innovation while ensuring consumer trust and satisfaction. The evolving landscape of material science will continue to depend on such rigorous testing protocols to meet the demands of modern applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy