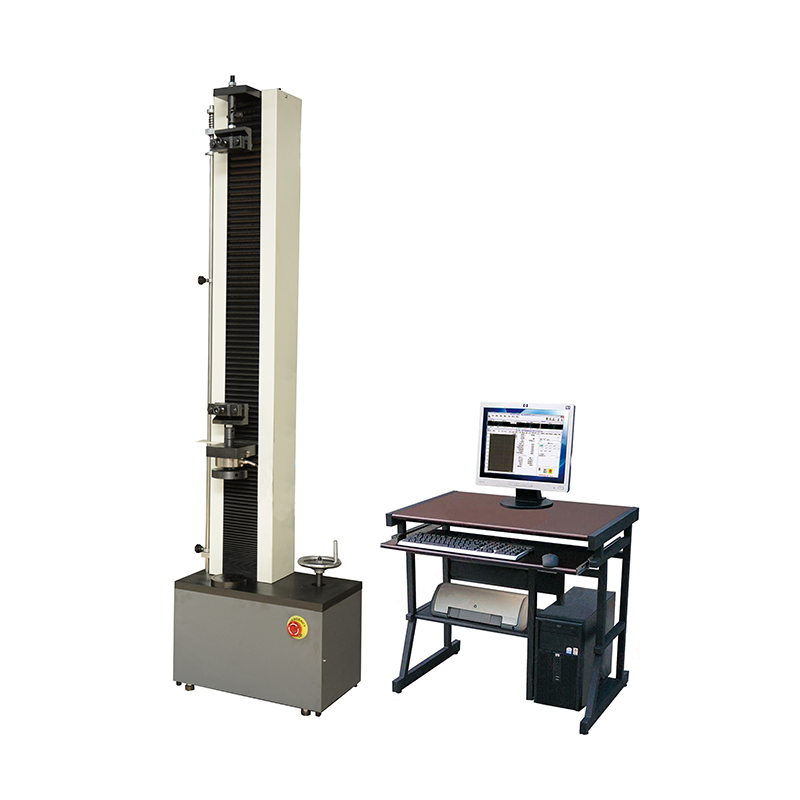

tensile tester astm d412

Understanding ASTM D412 The Tensile Tester for Rubber and Elastomers

The ASTM D412 standard test method is a critical protocol used in the materials testing industry, particularly for determining the tensile properties of rubber, elastomers, and other polymer materials. This standard, developed by ASTM International, is crucial for manufacturers, researchers, and engineers who require a precise understanding of the mechanical properties of rubber products. In this article, we’ll explore the significance of ASTM D412, its testing procedures, and its applications in various industries.

Significance of ASTM D412

ASTM D412 provides a standardized framework for evaluating the tensile characteristics of rubber and elastomers. Understanding these properties is essential for several reasons

1. Material Selection Different applications require specific mechanical properties. By adhering to ASTM D412, manufacturers can ensure that the materials they select will meet performance requirements under stress.

2. Quality Control Regular testing according to ASTM D412 helps maintain product consistency. It allows manufacturers to identify defects and assess the quality of their materials by benchmarking them against established standards.

3. Research and Development For researchers working on new elastomer formulations, the data obtained from ASTM D412 tests aids in material evaluation and comparison, guiding the development process.

Testing Procedures

The ASTM D412 test method involves several key steps

. Below is a simplified overview of the process1. Sample Preparation Specimens are cut from the rubber material as per the prescribed dimensions in the ASTM D412 standard. The commonly used shapes for test specimens are typically dumbbell-shaped, which ensures uniform stress distribution during the test.

2. Testing Environment The tests are usually conducted at room temperature, but the standard allows for modifications based on specific requirements. It is essential to perform tests in a controlled environment to avoid anomalies.

tensile tester astm d412

3. Tensile Testing Machine A tensile tester, equipped with appropriate grips to hold the sample, is used to apply a uniaxial load. The machine pulls the sample at a constant strain rate until failure occurs.

4. Measurements The tensile properties measured typically include the ultimate tensile strength, elongation at break, and Modulus at specified elongation points. Data is collected in stress-strain form, allowing for detailed analysis of the material's behavior under load.

5. Data Analysis Once the test concludes, results are analyzed to determine key metrics. These metrics provide insights into the material’s performance, helping engineers and designers make informed decisions.

Applications of ASTM D412

The ASTM D412 standard finds applications across various industries due to the extensive use of rubber and elastomers. Here are some notable applications

1. Automotive Industry Rubber components in vehicles, such as tires, seals, and hoses, must meet stringent performance and safety standards. ASTM D412 testing helps ensure these parts can withstand mechanical stress and environmental factors.

2. Construction Elastomeric materials used in building applications, such as roofing membranes or expansion joints, benefit from ASTM D412 testing for durability and elasticity.

3. Consumer Goods Many everyday products, including footwear, latex gloves, and inflatable toys, are made from rubber. Quality assurance through ASTM D412 ensures these items meet safety and performance criteria.

4. Medical Devices The healthcare industry relies on elastomers for pumps, syringes, and various personal protective equipment. ASTM D412 testing is crucial in guaranteeing that these materials can perform safely and effectively.

Conclusion

In summary, ASTM D412 plays a vital role in the evaluation of tensile properties for rubber and elastomer materials. By providing a standardized approach to mechanical testing, it aids industries in ensuring product quality, performance, and safety. As technology evolves and new applications for rubber and elastomers emerge, adherence to standards such as ASTM D412 will continue to be imperative for maintaining high-quality materials in a competitive market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy