tensile tester astm d412 factory

Understanding the ASTM D412 Tensile Tester A Comprehensive Guide

In the fields of material science and engineering, evaluating the tensile properties of a material is critical to ensuring its performance in various applications. ASTM D412 is one of the most widely recognized standards for testing the tensile strength of rubber, elastomers, and other flexible materials. This guide delves into the significance of the ASTM D412 tensile tester, its methodology, and the impact it has on industries reliant on material performance.

What is ASTM D412?

ASTM D412 is a standard test method established by the American Society for Testing and Materials (ASTM) that outlines the procedure for determining the tensile properties of vulcanized rubber and thermoplastic elastomers. The test is essential for understanding how materials will respond to stretching and other forces, which can be crucial for applications in automotive, aerospace, medical devices, and many other sectors.

The Importance of the Tensile Tester

The tensile tester is pivotal in assessing the mechanical properties of materials. Essentially, it measures how materials deform and fail under tension, providing valuable data such as tensile strength, elongation at break, and Young's modulus. These properties help engineers and designers select the appropriate materials for specific applications, ensuring safety, reliability, and performance.

How the Test is Conducted

The ASTM D412 test involves the following steps

1. Sample Preparation Specimens are prepared in accordance with the standard dimensions outlined in ASTM D412. Typically, samples are cut into specific shapes to facilitate accurate measurement.

tensile tester astm d412 factory

2. Testing Procedure The samples are placed in a tensile testing machine, which applies a controlled tension until the material breaks. The elongation is measured throughout the process.

3. Data Collection The machine records the force applied and the corresponding elongation of the material. This data is crucial for plotting a stress-strain curve, which visually represents the material’s response to stress.

4. Analysis After the test, parameters such as the maximum tensile strength, elongation percentage at break, and the modulus of elasticity are calculated. These values are used to assess the material’s performance and compliance with industry standards.

Impact on Industries

The implications of ASTM D412 testing are vast. Industries that rely on rubber and elastomeric materials, such as automotive manufacturers, prioritize adherence to this standard to ensure that components endure dynamic loads and environmental factors. For instance, tires, seals, and gaskets often depend on the material's tensile strength and elasticity to perform optimally under pressure and temperature variations.

Furthermore, compliance with ASTM D412 can influence product safety certifications, impacting marketability and regulatory approvals. Manufacturers who adhere to this standard can assure their clients of the material's reliability, which enhances business reputation and competitiveness.

Conclusion

In summary, the ASTM D412 tensile tester is an indispensable tool for determining the tensile properties of flexible materials. Understanding the methodology and significance of this test ensures that industries can maintain high standards of material performance and reliability. As technology and materials continue to evolve, adherence to ASTM D412 will remain a cornerstone in the pursuit of innovation and excellence in material applications.

-

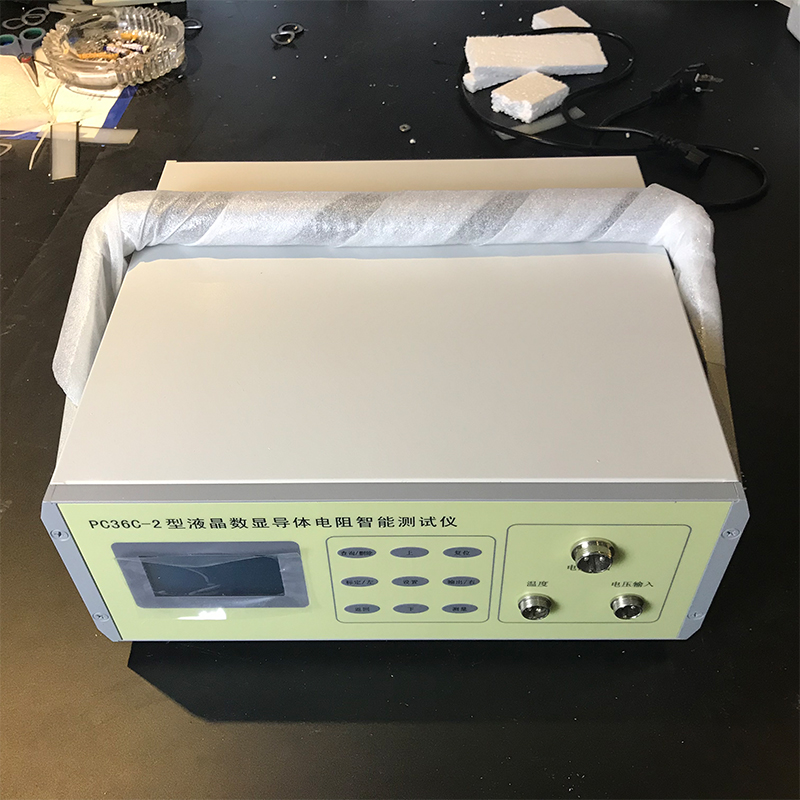

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy