tensile tester astm d412 factory

Understanding the ASTM D412 Tensile Tester A Vital Tool for Material Analysis

The ASTM D412 standard test method is crucial for evaluating the tensile properties of rubber, elastomers, and other flexible materials. As industries increasingly rely on these materials for a wide range of applications, understanding their mechanical properties—such as tensile strength, elongation, and modulus—is essential. The tensile tester, built to meet the ASTM D412 standard, plays a significant role in this analysis.

What is ASTM D412?

ASTM D412 is a testing standard established by the American Society for Testing and Materials (ASTM) that specifies the procedure for determining the tensile properties of rubber, including the maximum elongation and tensile strength. The results obtained from this test are critical for manufacturers and engineers to ensure that the materials chosen for their products meet specific performance criteria and safety standards.

Key Features of the ASTM D412 Tensile Tester

A factory capable of producing tensile testers that comply with ASTM D412 specifications incorporates various critical features. One of the most important aspects is the machine's ability to apply a controlled tensile load uniformly across the sample. Precision in load application is vital to obtaining accurate and repeatable results.

Most ASTM D412 tensile testers come equipped with a user-friendly interface that allows operators to set parameters easily and monitor the testing process in real-time. Modern tensile testers often incorporate advanced software that can provide detailed analyses of the data collected, including strain and stress curves. This capability helps in understanding the material performance better and aids in quality control processes.

Additionally, the construction of the testing grips must ensure that the specimen is held securely throughout the test to prevent slippage, which could lead to inaccurate results. Different grip designs can be utilized based on the material type and test requirements, providing versatility in material testing.

tensile tester astm d412 factory

Importance of Sample Preparation

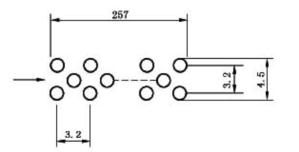

Effective sample preparation is paramount in obtaining reliable results from ASTM D412 testing. Samples must be cut precisely to the dimensions specified in the standard and should be free of imperfections such as air bubbles, tears, or foreign materials that could affect performance. Each specimen must be carefully labeled and documented to maintain consistency during testing and ensure that results are traceable.

Applications of Tensile Testing

The applications of ASTM D412 tensile testing are vast and varied. Industries such as automotive, aerospace, and consumer goods—where rubber and flexible materials are heavily utilized—rely on these tests to validate material performance. For instance, in the automotive sector, components like seals, gaskets, and tires must withstand various mechanical stresses, making it imperative to understand their tensile properties to ensure durability and safety.

Moreover, research and development teams utilize tensile testing to explore new material formulations and innovations. By conducting ASTM D412 tests on different blends of elastomers or incorporating additives, researchers can tailor materials to meet specific performance criteria or enhance durability.

Conclusion

In conclusion, the ASTM D412 tensile tester is a vital instrument in material testing that aids in the understanding of the mechanical properties of rubber and elastomers. Its application spans various industries and plays a crucial role in quality assurance, material development, and compliance with safety standards. As technology evolves and industries continue to innovate, the precision and reliability of tensile testing will remain fundamental in driving material science forward. Factories that produce these testers must prioritize adherence to standards, ensuring that every device is equipped to meet the rigorous demands of material analysis.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy