Top Exporters of Tensile Testing Machines and Equipment Worldwide

The Global Market for Tensile Testers Exporters and Trends

In the ever-evolving field of material testing, tensile testers play a pivotal role in determining the strength and durability of materials. These sophisticated machines are essential for various industries, including construction, manufacturing, aerospace, and automotive. The demand for tensile testers has seen a significant upward trend, leading to a vibrant global market for exporters specializing in this critical equipment.

Tensile testing is a fundamental process that assesses how materials respond to forces being applied in tension. This testing method helps in understanding material properties such as tensile strength, yield strength, elongation, and modulus of elasticity. The data obtained from tensile tests are vital for engineers and manufacturers to design safe and reliable products, ensuring they meet stringent safety standards.

Current Market Trends

The growing emphasis on quality control and safety in manufacturing processes has propelled the demand for tensile testers. Industries are increasingly implementing rigorous testing protocols to comply with international standards, which fuels the need for reliable testing equipment. As a result, the tensile tester market is projected to witness substantial growth in the coming years.

Moreover, advancements in technology have led exporters to develop more sophisticated tensile testing machines. The integration of digital technologies, such as computer control and data acquisition systems, has made it easier for users to obtain precise and accurate measurements. Features like real-time data analysis, improved user interfaces, and enhanced reporting capabilities are becoming essential selling points for exporters in the global marketplace.

Key Exporters in the Market

Leading exporters of tensile testers include both established manufacturers and emerging companies worldwide. These exporters offer a wide range of products, from basic models designed for educational purposes to high-end machines used in industrial applications. Notable players in the market have adopted innovative strategies to capture a larger share, such as focusing on customer service, product customization, and establishing strategic partnerships.

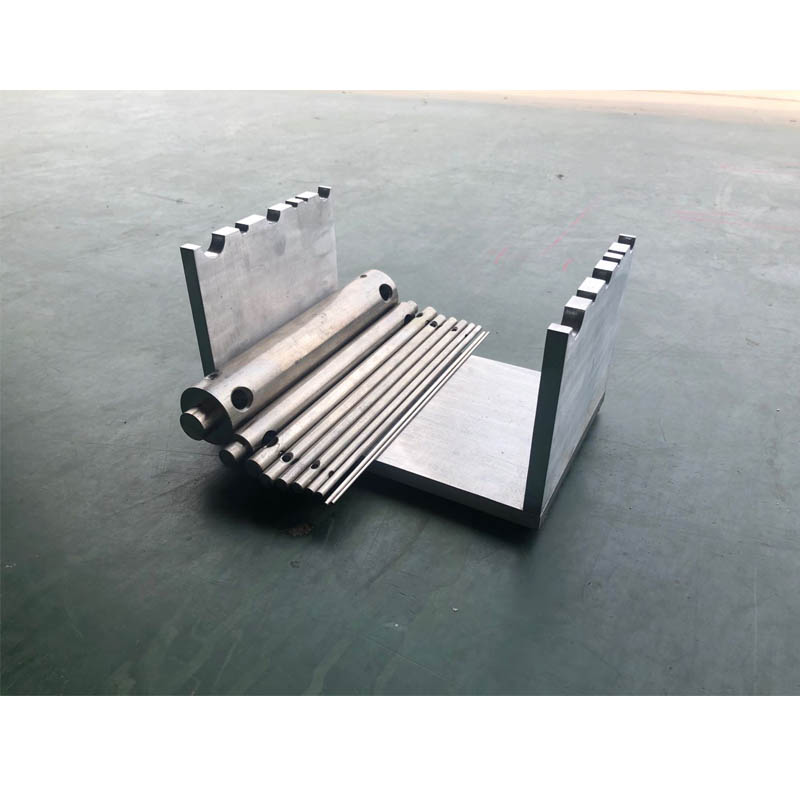

tensile tester exporters

Countries like Germany, the United States, Japan, and China are recognized as major hubs for tensile tester manufacturers. German companies, in particular, are renowned for their engineering precision and high-quality equipment, dominating the European market. American manufacturers focus on integrating cutting-edge technology and automation in their products, catering to advanced research and industrial applications. Meanwhile, China has rapidly emerged as a competitive player in the global market, offering cost-effective solutions to meet diverse customer needs.

Challenges Faced by Exporters

Despite the promising outlook, exporters of tensile testers face several challenges. The global market landscape is highly competitive, with numerous players vying for market share. This situation necessitates continuous innovation and differentiation to meet customer expectations. Additionally, traders must be aware of varying international regulations and standards, which can complicate export processes.

Another challenge is the fluctuating costs of raw materials and components, which can impact production costs and profit margins. Exporters must develop effective supply chain strategies to mitigate these risks and ensure timely delivery of their products.

Future Prospects

Looking ahead, the tensile tester market is poised for significant growth. The increasing demand for advanced materials, particularly in sectors such as aerospace and biotechnology, necessitates rigorous material testing. Furthermore, as industries continue to prioritize sustainability and eco-friendliness, tensile testing will play an essential role in the development of new, innovative materials that meet these criteria.

Exporters should also consider the emerging trend toward remote testing capabilities, driven by the need for flexibility in operations. The COVID-19 pandemic has accelerated the shift towards digitalization and remote work, prompting manufacturers to seek solutions that allow for remote monitoring and control of testing processes.

In conclusion, the global market for tensile testers is expanding, driven by technological advancements, increasing industry standards, and the need for robust quality assurance measures. Exporters who adapt to these changing dynamics by leveraging innovation and focusing on customer needs will undoubtedly thrive in this competitive landscape. As the importance of material testing continues to grow across various sectors, the future remains bright for exporters of tensile testers.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy