Tensile Testing Equipment Manufacturer for Accurate Material Strength Analysis and Quality Control

The Importance of Tensile Tester Factories in Material Testing

In the realm of materials science and engineering, understanding the properties of materials is crucial. One key aspect of material properties is tensile strength, which refers to the resistance of a material to breaking under tension. Tensile testers are sophisticated machines designed to measure this property. As industries innovate and evolve, the demand for precise and reliable testing equipment continues to grow, highlighting the importance of tensile tester factories.

A tensile tester, also known as a tensile testing machine, is essential in many sectors, including construction, automotive, aerospace, and manufacturing. These machines play a vital role in quality control and assurance, helping manufacturers ensure that their products meet both safety standards and performance requirements. A tensile tester operates by applying a controlled tensile force to a material specimen until it fails. During this process, it records various parameters such as elongation, yield strength, ultimate tensile strength, and modulus of elasticity.

The Importance of Tensile Tester Factories in Material Testing

One key factor that distinguishes leading tensile tester factories is their commitment to innovation. As materials science advances, new materials with unique properties are developed. Consequently, tensile testers must evolve to accommodate these changes. Factories are consistently researching new technologies, such as digital and automatic control systems, to enhance the functionality of their machines. Internet of Things (IoT) integration is becoming increasingly popular, allowing for remote monitoring and data analysis, which streamlines the testing process and improves efficiency.

tensile tester factory

Quality control is another major focus for tensile tester factories. These machines must meet stringent industry standards, and thus undergo rigorous testing and calibration before they reach the market. Factories comply with international standards such as ASTM and ISO, ensuring that their machines deliver reliable results. Furthermore, factories often provide certification processes for their machines, giving clients confidence in their investment.

In addition to producing high-quality machines, tensile tester factories must also prioritize customer support and service. The relationship between the manufacturer and the client does not end with a sale. Offering comprehensive training for operators, maintenance services, and prompt technical support is essential for client satisfaction. Factories that excel in customer service build long-term relationships, fostering trust and loyalty among their client base.

Sustainability is another important consideration for modern tensile tester factories. As industries globally strive to reduce their environmental footprint, many factories are implementing eco-friendly practices. This includes using sustainable materials in the manufacturing process, reducing waste, and improving energy efficiency in their production facilities. By adopting these practices, tensile tester factories not only contribute to environmental sustainability but also appeal to a growing market of eco-conscious consumers.

Moreover, globalization has expanded the market for tensile testers. Factories now often serve a worldwide clientele, necessitating an understanding of the different regulations and standards in various countries. This global perspective encourages factories to remain versatile and adaptive, guaranteeing they meet the diverse needs of their customers.

In conclusion, tensile tester factories play a fundamental role in the field of material testing. Their commitment to innovation, quality control, customer support, and sustainability continues to drive the advancement of product testing technologies. As industries grow and change, the demand for reliable tensile testing solutions from these factories will undoubtedly increase. By investing in research and development and maintaining high standards, tensile tester factories are well-positioned to lead the way in material testing, ensuring safety and quality in products across numerous sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

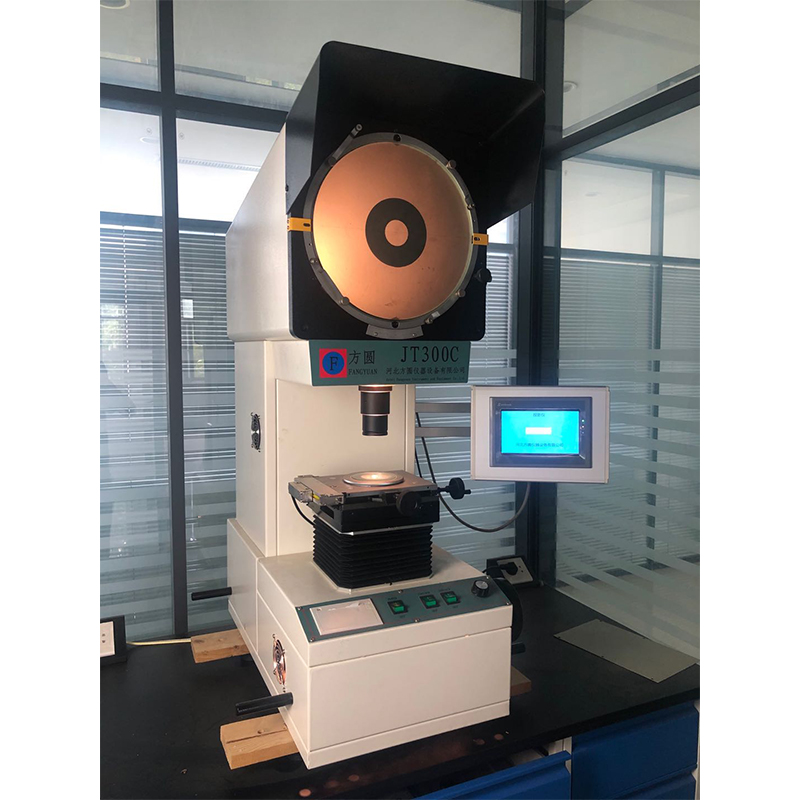

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy