Exporter of Fixtures for Tensile Testing Equipment and Accessories

The Role of Tensile Tester Fixtures in Material Testing A Focus on Exporters

In the realm of material testing, tensile testing stands as one of the most crucial procedures employed to determine the mechanical properties of various materials. This testing is designed to evaluate a material's response to a uniaxial tensile load, providing insights into its strength, ductility, and elasticity. Essential to the effectiveness of tensile testing are the fixtures used to hold and manipulate the materials being tested. This article explores the importance of tensile tester fixtures, particularly in the context of exporters who provide these essential tools to laboratories and testing facilities worldwide.

Understanding Tensile Tester Fixtures

Tensile tester fixtures are specialized tools used to securely hold the sample material during the tensile test. They come in various shapes and sizes, customized to accommodate different materials such as metals, plastics, composites, and textiles. These fixtures are designed to ensure that the material remains stable under load, preventing slippage or misalignment, which could result in inaccurate test results.

The design of these fixtures is critical as they must adhere to specific standards and requirements. They play a pivotal role in obtaining consistent and repeatable results during testing. Properly designed fixtures minimize the introduction of variables that might affect the test outcomes, such as uneven pressure distribution or improper alignment.

The Export Market for Tensile Tester Fixtures

As industries around the world recognize the importance of reliable tensile testing, the demand for high-quality tensile tester fixtures has surged. Exporters of these fixtures are capitalizing on this trend by providing various options tailored to meet the diverse needs of clients across multiple sectors, including automotive, aerospace, construction, and manufacturing.

Exporters are often at the forefront of innovation in fixture design. They understand that materials and testing standards vary from country to country, necessitating a flexible approach to design and manufacturing. By offering customizable solutions, exporters can meet the specific requirements of international customers, ensuring that they adhere to local compliance and testing standards.

tensile tester fixtures exporter

Quality and Compliance

One of the significant challenges faced by exporters of tensile tester fixtures is maintaining quality and compliance with international standards. Fixtures must be manufactured from high-grade materials to withstand the rigors of tensile testing, including high tensile loads and environmental conditions. Moreover, they must comply with ASTM, ISO, and other relevant standards to ensure they are fit for purpose.

Many exporters invest heavily in research and development to create fixtures that not only meet but exceed these standards. By utilizing advanced manufacturing techniques, such as CNC machining and 3D printing, exporters can produce fixtures that offer enhanced precision and reliability. Additionally, by implementing rigorous quality control measures, they can guarantee that each fixture leaving their facility meets the established benchmarks.

The Future of Tensile Tester Fixtures

As technology advances, the future of tensile tester fixtures is poised for exciting developments. Digitalization and automation are likely to play significant roles, with new fixtures designed to integrate seamlessly with testing machines, allowing for real-time data acquisition and analysis. This evolution will enable testing laboratories to obtain faster and more accurate results, enhancing their ability to innovate and improve material properties.

Furthermore, as industries continue to pursue sustainable practices, manufacturers are increasingly mindful of the environmental impact of their products. Exporters are now exploring eco-friendly materials and production processes, enabling them to contribute positively to global sustainability efforts while meeting the functional demands of their clients.

Conclusion

Tensile tester fixtures represent a vital component of the material testing process, ensuring accuracy and reliability in assessing material properties. For exporters, the ability to provide high-quality, compliant fixtures that cater to the diverse needs of international markets presents a significant opportunity. As the industry evolves, staying ahead in terms of quality, innovation, and sustainability will be key to success in this competitive landscape. Exporters that embrace these challenges will continue to thrive in the global market, contributing to the advancement of materials science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

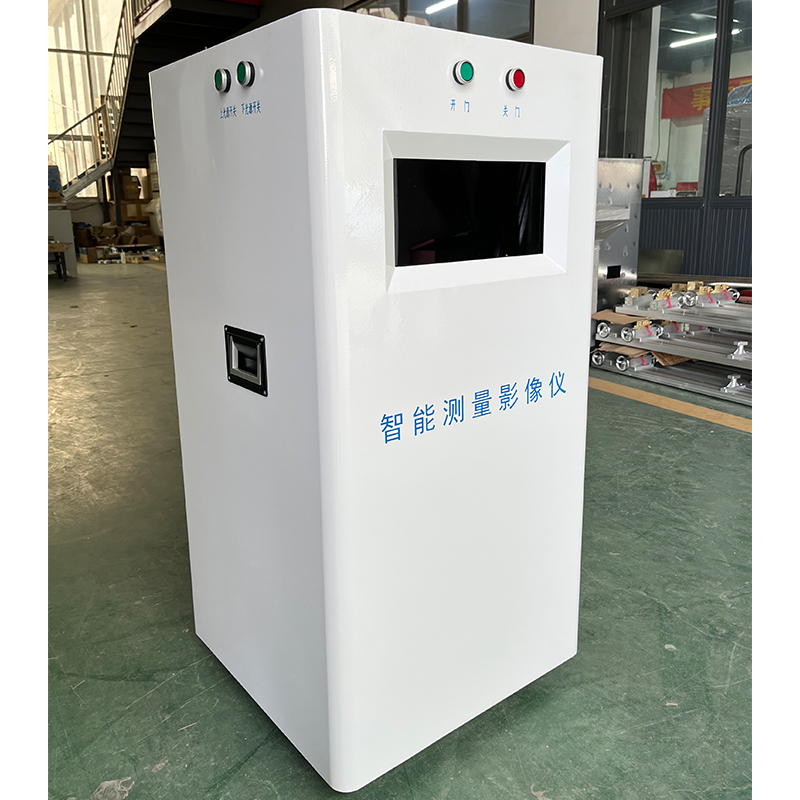

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy