tensile tester for break strength company

Exploring the Role of Tensile Testers in Evaluating Break Strength

In various industries, understanding material properties is crucial for ensuring safety, durability, and performance of products. One fundamental property that engineers and quality control specialists focus on is break strength, which measures a material's resistance to breaking under tension. To accurately determine break strength, tensile testers play a pivotal role. This article delves into the significance of tensile testers, their functionality, and their impact on quality assurance in manufacturing processes.

What is a Tensile Tester?

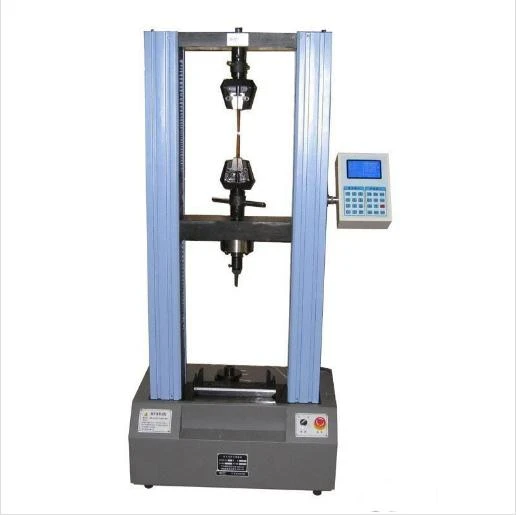

A tensile tester, also known as a tensile testing machine or universal testing machine, is an apparatus designed to measure the mechanical properties of materials. It operates by applying a uniaxial tensile load to a sample specimen, which is typically in the form of a standardized shape and size. As the load is applied, the tester records the material's response until failure occurs, enabling the calculation of various critical parameters, including break strength, elongation, and modulus of elasticity.

Importance of Break Strength Testing

Break strength testing is essential for several reasons. First and foremost, it ensures that materials can withstand the stresses they will encounter in their intended application. For instance, in the aerospace and automotive industries, components are subjected to high levels of stress; understanding the break strength of materials used in these applications can prevent catastrophic failures.

Moreover, break strength testing contributes to compliance with industry standards and regulations. Many sectors, such as construction and manufacturing, have strict guidelines that dictate acceptable material properties. Tensile testers help manufacturers guarantee that their products meet these standards, thus maintaining safety and quality.

The Testing Process

The process of tensile testing involves several steps

1. Sample Preparation Specimens are prepared according to standardized dimensions, typically following ASTM or ISO guidelines to ensure consistency.

tensile tester for break strength company

2. Mounting The specimen is securely mounted in the tensile tester between two grips.

4. Data Collection Throughout the test, the machine records the load and corresponding elongation of the specimen. This data is crucial for plotting a stress-strain curve, which visually represents how the material behaves under stress.

5. Analysis After the test, engineers analyze the data to determine key metrics, including the maximum load at break, the percentage elongation (which indicates ductility), and the yield strength.

Advancements in Tensile Testing Technology

Modern tensile testers are equipped with advanced technology that enhances accuracy and efficiency. Many machines now feature computerized systems that automate data collection and analysis, reducing the potential for human error. Moreover, digital interfaces allow for real-time monitoring of the testing process, and advanced software enables sophisticated analysis of results.

Another trend in tensile testing technology is the development of portable testers. These devices allow for in-situ testing, meaning that materials can be tested on-site, which is particularly beneficial for construction projects or field research. This portability ensures that quality control can be maintained throughout the entire lifecycle of a project, from material selection to final inspection.

Conclusion

As industries continue to evolve and demand higher quality materials, the importance of tensile testers for break strength evaluation cannot be overstated. These machines provide invaluable data that inform engineering decisions, ensuring safety and reliability in countless applications. With advancements in technology making testing more accessible and efficient, tensile testers are destined to remain a cornerstone of material science and quality assurance in manufacturing. By investing in robust tensile testing practices, companies can enhance their product quality, improve customer satisfaction, and maintain a competitive edge in the market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy