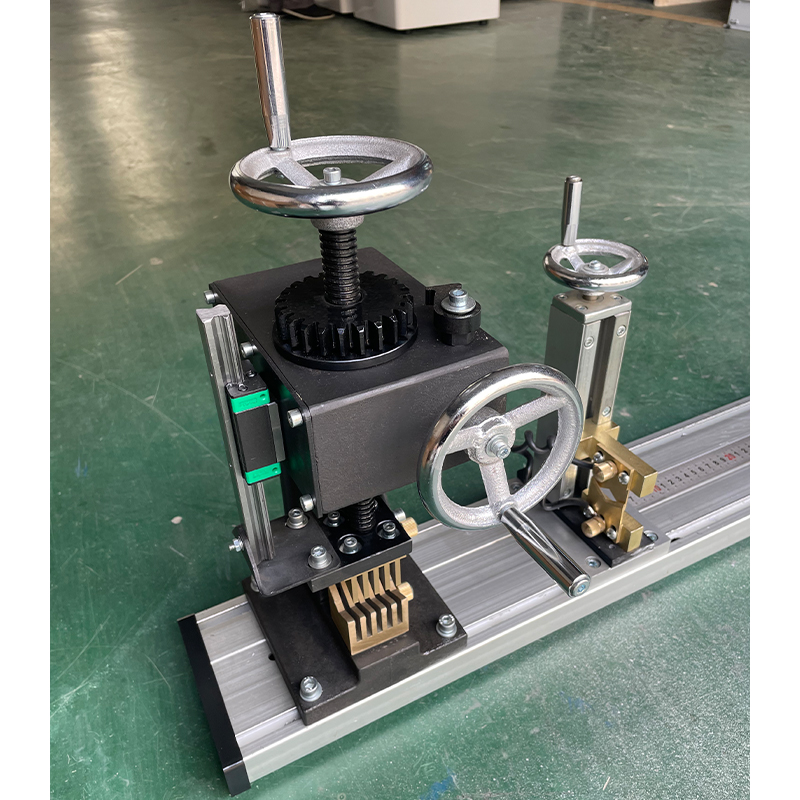

tensile tester for break strength suppliers

Understanding Tensile Testers for Break Strength A Guide for Suppliers

Tensile testers are essential instruments in various industries, used to determine the break strength of materials. These machines provide critical data that can influence product design, quality control, and regulatory compliance. For suppliers of tensile testing equipment, understanding the significance of these tests and the technological advancements in tensile testers is crucial.

What is a Tensile Tester?

A tensile tester, also known as a universal testing machine (UTM), measures the force required to stretch a material until it breaks. It applies tension to a specimen at a controlled rate, recording the force and elongation until failure occurs. This process generates a stress-strain curve, offering invaluable insights into a material’s properties, such as tensile strength, yield strength, elongation at break, and other mechanical attributes.

Importance of Break Strength Testing

Break strength is a critical parameter in many industries, including textiles, plastics, metals, and construction. Understanding a material's break strength helps manufacturers ensure that their products can withstand the applied loads during usage without failure. In sectors such as aerospace, automotive, and construction, where safety is paramount, knowing the break strength of materials can prevent catastrophic failures and ensure compliance with industry standards.

Technological Advances in Tensile Testing

tensile tester for break strength suppliers

Modern tensile testers come equipped with advanced features that enhance their functionality. Automation has made tensile testing more efficient, with machines capable of performing tests with minimal human intervention. Digital interfaces and software enable real-time data analysis, allowing engineers to make informed decisions quickly. Many systems now offer extensometers, which provide precise measurements of elongation, leading to more accurate results.

Moreover, the integration of artificial intelligence (AI) and machine learning algorithms has begun to transform the way tensile testing data is analyzed. These technologies can identify patterns and predict material failure points, helping suppliers to improve their product offerings through data-driven insights.

Choosing the Right Supplier

For businesses looking to invest in tensile testing equipment, selecting the right supplier is crucial. Suppliers should provide not only high-quality machines but also comprehensive support, including installation, calibration, and training. Additionally, an established supplier should offer a range of testing solutions tailored to specific industry needs. Whether it's a manual machine for small-scale operations or a fully automated system for high-volume testing, the supplier’s offerings should align with the customer's requirements.

Conclusion

As industries continue to evolve, the demand for reliable tensile testing equipment will only grow. Tensile testers play a vital role in ensuring material integrity and safety across various applications. For suppliers, staying updated with technological advancements and understanding the needs of their customers is essential for long-term success. By providing high-quality tensile testing solutions and excellent support, suppliers can establish themselves as leaders in the market, contributing to the advancement of material science and engineering.

In a competitive landscape, those who prioritize innovation and customer service will thrive, helping manufacturers ensure that their products meet the stringent demands of safety and performance in today's market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy