tensile tester for sale suppliers

The Rise of Tensile Testers A Guide for Buyers and Suppliers

In today's industrial landscape, the demand for tensile testers has been steadily rising, driven by the need for quality assurance and material testing in various sectors. Tensile testers, also known as universal testing machines, are vital in determining the material properties of different substances, including metals, plastics, and textiles. This equipment measures how materials respond to stress and strain, providing critical data that manufacturers can leverage to improve their products.

For suppliers of tensile testers, understanding the market demand and the specific needs of various industries is essential. Manufacturers in sectors such as construction, aerospace, automotive, and electronics rely heavily on these machines to ensure the integrity and durability of their materials. Quality control processes often require frequent testing, making the availability of reliable tensile testers a necessity.

When searching for tensile testers for sale, prospective buyers should consider several factors to ensure they choose the right equipment for their needs. First and foremost is the type of tensile tester required - either a manual or an automatic system. Automatic systems often provide greater accuracy and ease of use, while manual testers can be more cost-effective for smaller operations or specific applications.

Another important aspect to consider is the load capacity of the tensile tester

. Different materials have varying tensile strength, and selecting a machine with the appropriate range is crucial. Suppliers typically offer machines with various load capacities to accommodate the testing needs of their customers.tensile tester for sale suppliers

Additionally, buyers should take into account the features and specifications of a tensile tester. Digital displays, data logging facilities, and software compatibility are just a few of the features that can enhance the testing process. Advanced models may come equipped with analytical software that generates comprehensive reports, allowing manufacturers to make data-driven decisions.

Moreover, accuracy and calibration standards are paramount in the selection process. Buyers should inquire about the calibration methods and frequency used by the supplier to ensure the reliability of the data obtained from tests. Suppliers with a proven track record in maintaining and calibrating their equipment will instill more confidence in buyers looking for quality testing solutions.

Price is another critical consideration. While it is tempting to opt for the least expensive model, it is essential to balance cost with quality and performance. Investing in a high-quality tensile tester may incur a higher upfront cost, but the long-term benefits of accurate and reliable testing often outweigh initial savings.

Finally, after-sales service is a key factor in establishing a successful supplier-buyer relationship. Reliable suppliers should offer support, maintenance, and training to ensure that customers can maximize their investment.

In conclusion, the market for tensile testers is expanding, with numerous suppliers positioned to meet the growing demand. Buyers should approach their selection process with careful consideration of their specific testing needs, material types, and budget. By doing so, they can successfully navigate the marketplace and invest in equipment that will enhance the quality and reliability of their products.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

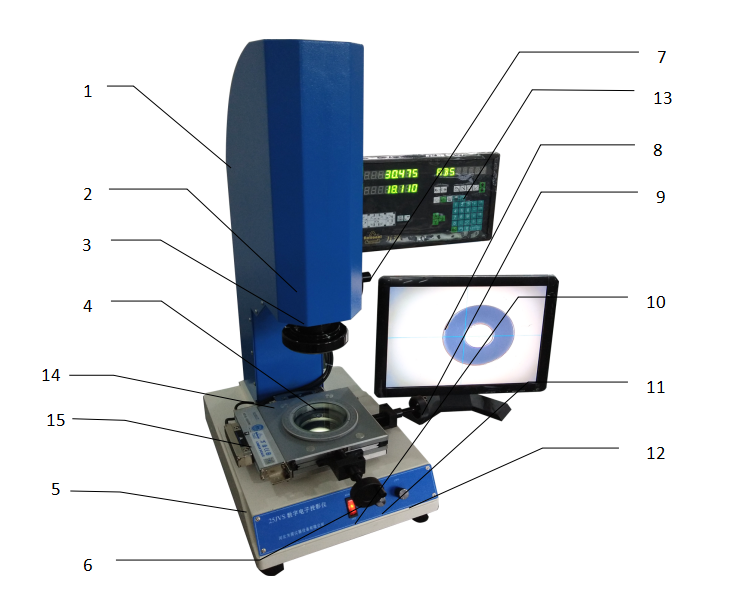

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy