Exporter of High-Quality Tensile Tester Grips for Reliable Material Testing

The Importance of Tensile Tester Grips in Material Testing Export

Tensile testing is an essential procedure in material science, engineering, and manufacturing, as it helps to determine the mechanical properties of materials. Among the vital components of tensile testing machines are the grips, which secure the material sample during the test. As global demand for advanced testing equipment grows, the role of tensile tester grips exporters has become increasingly significant.

Understanding Tensile Tester Grips

Tensile tester grips are designed to hold a specimen while it is subjected to tensile stress. These grips are critical because they must prevent slippage while allowing accurate data collection during the test. There are various types of grips, including mechanical grips, hydraulic grips, pneumatic grips, and customized fixtures tailored for specific materials. Each type of grip has its advantages and applications, depending on the material being tested.

Mechanical Grips These grips use a clamping mechanism to hold the specimen. They are often adjustable to accommodate different thicknesses and widths of materials. Mechanical grips are favored for their simplicity and reliability.

Hydraulic and Pneumatic Grips These grips use fluid power to maintain holding force. They can automatically adjust to different specimen sizes and apply consistent pressure, making them ideal for high-stress tests or applications where precise control is required.

Custom Grips Tailored solutions are often necessary for specific applications, especially in industries such as aerospace, automotive, and construction, where materials can vary significantly in size and shape.

The Role of Exporters

Tensile tester grips exporters play a crucial role in distributing these invaluable components on a global scale. As industries worldwide increasingly seek to improve their material testing capabilities, high-quality grips have become indispensable. Exporters are responsible for sourcing, manufacturing, and supplying these grips to laboratories, research facilities, and manufacturers across various sectors.

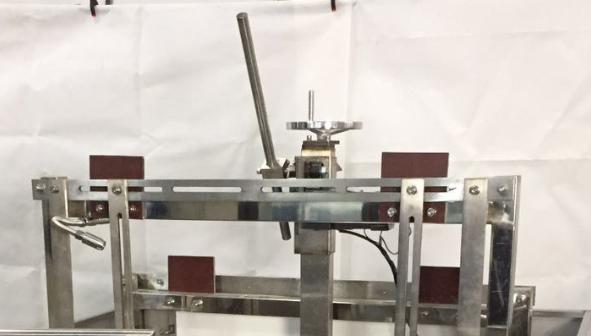

tensile tester grips exporter

Quality and Compliance One of the primary responsibilities of exporters is to ensure that the grips they supply meet international standards and regulations. This includes certifications from organizations such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). Compliance guarantees that the grips will perform reliably during testing and produce accurate results, which is vital for industries that rely on precision and safety.

Market Trends and Challenges

The global market for tensile testing equipment, including grips, is witnessing significant growth. This trend is driven by advancements in material science, as new composite materials and alloys are developed for various applications. As a result, the demand for high-performance testing equipment, including specialized grips, is on the rise.

However, exporters face several challenges in this evolving market. The competitive landscape requires them to continually innovate and adapt to new technologies and customer needs. Additionally, logistical challenges such as shipping and tariffs can affect the cost and availability of grips.

The Future of Tensile Tester Grips Export

As industries move towards automation and increased efficiency, the future of tensile tester grips looks promising. Technological advancements, such as digital grips that can provide real-time data monitoring and automation features, are becoming more prevalent. Exporters who embrace these innovations can position themselves as leaders in the market.

Furthermore, collaboration between manufacturers and exporters can lead to the development of bespoke solutions that meet the specific requirements of niche industries. By investing in research and development, exporters can stay ahead of industry trends and cater to the evolving needs of their customers.

Conclusion

Tensile tester grips are a critical component in material testing that ensures the integrity and accuracy of results. The role of exporters in this sector is increasingly vital as they help facilitate the distribution of innovative and compliant products to meet the growing demand. As technology advances and industries evolve, the continuous adaptation of exporters will be essential to support the next generation of material testing solutions. The future of tensile tester grips is bright, promising opportunities for growth, innovation, and collaboration across the globe.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy