Tensile Testing Equipment Grips from Leading Manufacturing Factories Worldwide

Understanding Tensile Tester Grips A Comprehensive Overview of Factories and Their Importance

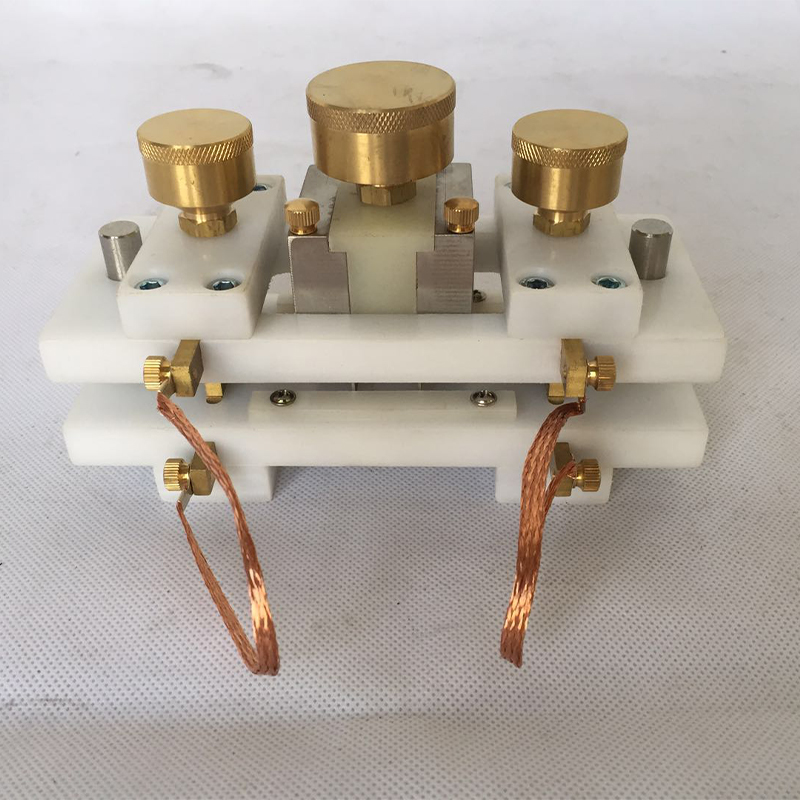

Tensile testing is a critical process in material science, quality control, and product development, as it helps determine a material's strength, ductility, and overall performance under stress. One of the essential components in tensile testing is the grips, which secure the specimen during the test. Understanding the factories that produce these grips is key to ensuring high-quality testing results.

The Role of Tensile Tester Grips

Tensile tester grips are designed to hold the material sample firmly in place while it is being pulled apart. This is crucial because any slippage or failure in grip can lead to inaccurate results. Different materials require specific types of grips. For example, metallic specimens may require serrated grips to prevent slippage, while softer materials might necessitate rubber-coated grips to avoid damage.

Types of Grips

There are several types of grips used in tensile testing, including

1. Serrated Grips These have a textured surface that provides a strong hold on the specimen, commonly used for metals. 2. Rubber-coated Grips Suitable for softer materials, preventing damage while providing a firm hold. 3. Pneumatic Grips These grips use air pressure to secure the specimen, allowing for quick adjustments and versatility across materials. 4. Mechanical Grips Operated manually, these grips are simple to use but require careful handling to ensure an effective hold.

Each type of grip serves a specific purpose, and selecting the right one is vital for obtaining accurate test results.

Leading Factories in Grip Production

tensile tester grips factories

The production of tensile tester grips requires advanced manufacturing processes and materials to ensure durability and performance. Many factories specialize in producing these components, combining precision engineering with high-quality materials.

1. Quality Assurance Leading factories implement stringent quality control measures. They often adhere to international standards such as ISO 9001, ensuring their grips are reliable and of consistent quality. 2. Material Selection Factories utilize high-grade materials, such as stainless steel and specialized polymers, to manufacture grips that can withstand the forces exerted during testing without failing.

3. Customized Solutions Many manufacturers offer custom grip solutions tailored to specific testing requirements. This flexibility allows researchers and engineers to select grips that precisely match their testing materials and methods.

4. Technological Integration Modern factories often integrate advanced technologies, such as CNC machining and 3D printing, allowing for rapid prototyping and the production of complex grip designs that enhance functionality.

Importance of Choosing the Right Factory

Selecting the right factory for tensile tester grips is crucial for the accuracy of tests conducted in laboratories and industrial settings. A reputable factory not only guarantees the quality of the grips but also provides excellent customer support and technical assistance when needed.

Furthermore, the evolution of manufacturing technologies means that staying up-to-date with the latest innovations can significantly impact testing quality. Factories that invest in research and development will likely produce grips that meet or exceed current industry standards.

Conclusion

Tensile tester grips are a vital component of the tensile testing process, making the role of manufacturing factories crucial in ensuring accurate and reliable testing outcomes. Understanding the different types of grips and the factories that produce them can help laboratories and industries make informed decisions about their tensile testing equipment. Investing in high-quality grips will ultimately lead to better product development, quality assurance, and material performance evaluation. In a world where precision is paramount, the selection of the right tensile tester grips can make all the difference.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy