High-Quality Tensile Tester Grips for Accurate Material Strength Evaluations and Testing

The Importance of Choosing the Right Tensile Tester Grips An Overview of Factory Options

In the realm of materials testing, precision and accuracy are paramount. Tensile testing is one of the most common methods used to evaluate the mechanical properties of materials, and it involves measuring the behavior of materials when subjected to tension. A critical component of this testing process is the tensile tester grips. These grips hold the specimen firmly while the tensile force is applied, ensuring that the test results accurately reflect the material's properties. This article will explore the role of tensile tester grips and the significance of selecting the right grips from a factory.

Understanding Tensile Tester Grips

Tensile tester grips are devices designed to securely hold a specimen during testing. They come in various styles and designs, tailored to different materials and testing requirements. The primary function of these grips is to apply a uniform load on the specimen without causing any damage or stress concentrations that could skew results.

Common types of grips include serrated grips, which are ideal for materials like metals and rigid plastics; rubber grips, which are suitable for softer materials and provide better friction; and pneumatic grips, which allow for quick release and adjustability. Each grip type has its advantages depending on the material being tested and the specific requirements of the test.

The Role of Factories in Producing Quality Grips

Choosing the right tensile tester grip can significantly impact the outcome of a tensile test. Factories specializing in the production of these grips play a crucial role in ensuring quality and consistency. A reputable factory invests in advanced technology and materials to manufacture grips that can withstand repeated testing cycles while maintaining their grip integrity.

Moreover, factories often offer customization options to cater to unique testing needs. Some companies may require grips that can accommodate unusual sample sizes or specific material characteristics. A factory that understands these requirements can provide tailored solutions that ensure accurate and reliable test results.

Material Selection and Design Considerations

tensile tester grips factory

When sourcing tensile tester grips from a factory, material selection and design are vital considerations. Grips made from high-strength materials can endure greater stress and offer increased durability, which is essential in a testing environment where precision is key.

Furthermore, the design of the grip itself affects the testing outcome. For instance, a grip with a wider surface area can distribute the load more evenly across the specimen, reducing the risk of premature failure due to localized stresses. Factories that specialize in grip design often employ engineers and experts who understand the nuances of material properties, ensuring that the grips they produce are not only effective but also innovative.

Quality Control and Standards

Quality control is another crucial aspect of manufacturing tensile tester grips. Factories adhere to strict industry standards to ensure that their products are reliable and consistent. This might include conducting routine tests on grips to evaluate their performance under various loading conditions.

In addition, factories often seek certifications from recognized bodies, which assures customers that the grips meet certain performance and safety standards. This aspect of manufacturing is vital for any laboratory or industrial environment where accuracy and reproducibility are critical.

Final Thoughts

Selecting the right tensile tester grips from a factory is an essential step in achieving accurate tensile testing results. The grips hold the specimen securely, ensuring that the forces applied during the test are distributed evenly and without introducing any unwanted variables. With advancements in technology and materials, factories that specialize in this equipment continue to innovate and provide tailored solutions for various testing needs.

In conclusion, whether for academic research, quality control in manufacturing, or product development, understanding the significance of tensile tester grips and the role of factories in producing them is fundamental. By investing in quality grips and collaborating with reputable manufacturers, laboratories can uphold the integrity of their testing processes and contribute to the advancement of material science. The careful selection of these seemingly minor components can lead to significant improvements in the accuracy and reliability of tensile testing outcomes, ultimately enhancing the quality of products and materials in various industries.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

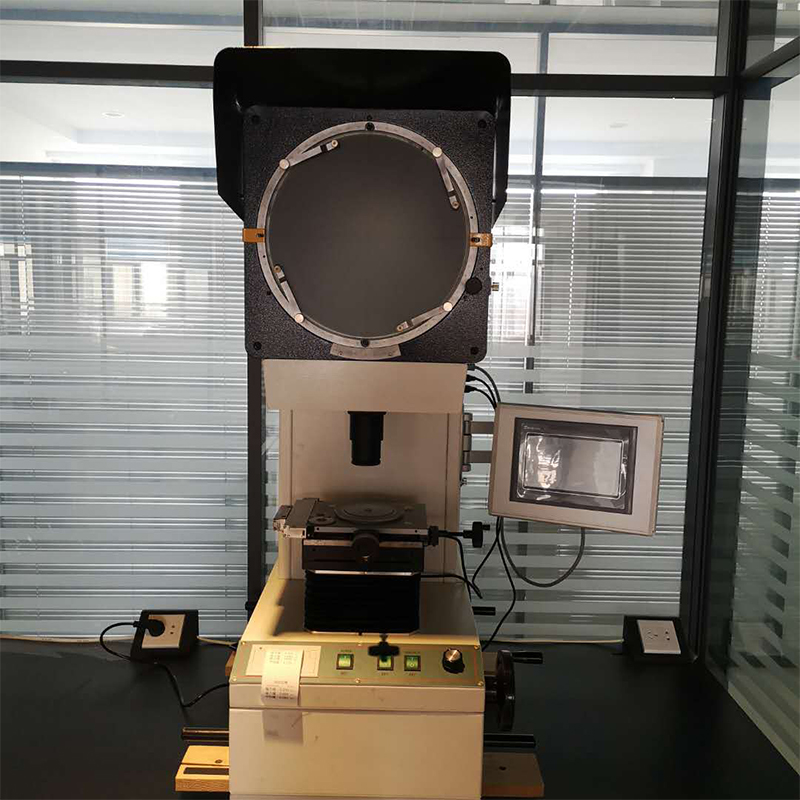

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy