Top Manufacturers of Tensile Testing Machines in the Industry Today

The Role of Tensile Tester Machine Factories in Modern Material Testing

Tensile tester machines are crucial tools in material science, widely used for evaluating the mechanical properties of various materials, including metals, plastics, and composites. Tensile testing determines how a material reacts to being pulled apart, providing vital data that helps manufacturers ensure product quality and compliance with industry standards. The factories that produce these machines play a significant role in advancing testing technology and meeting the growing demands of various industrial sectors.

Understanding Tensile Testing

At its core, tensile testing involves applying a controlled amount of tensile force to a sample until it fractures. The test measures properties such as tensile strength, elongation, and Young's modulus, which are critical for determining how materials will perform under stress. In sectors like construction, aerospace, and automotive, high-quality tensile testing is paramount as it can impact safety, durability, and overall performance.

The Importance of Factories in this Sector

Tensile tester machine factories are tasked with designing, developing, and manufacturing these sophisticated pieces of equipment. They combine engineering expertise with cutting-edge technology to produce machines that are accurate, reliable, and user-friendly. The factories often conduct rigorous testing and Quality Assurance (QA) processes to ensure that each machine meets stringent industry standards.

Innovation and Technology in Manufacturing

These factories are at the forefront of innovation in material testing technology. Advances in automation, digital data acquisition, and computer software integration have greatly enhanced the capabilities of tensile testers. Modern machines can now provide real-time data monitoring, automatic data logging, and advanced analysis, allowing operators to gain insights into material performance more efficiently.

Furthermore, the adoption of Industry 4.0 principles is transforming how tensile tester machine factories operate. The integration of smart technologies facilitates predictive maintenance, remote monitoring, and improved production efficiency. As a result, manufacturers can produce more reliable machines while reducing operational costs and lead times.

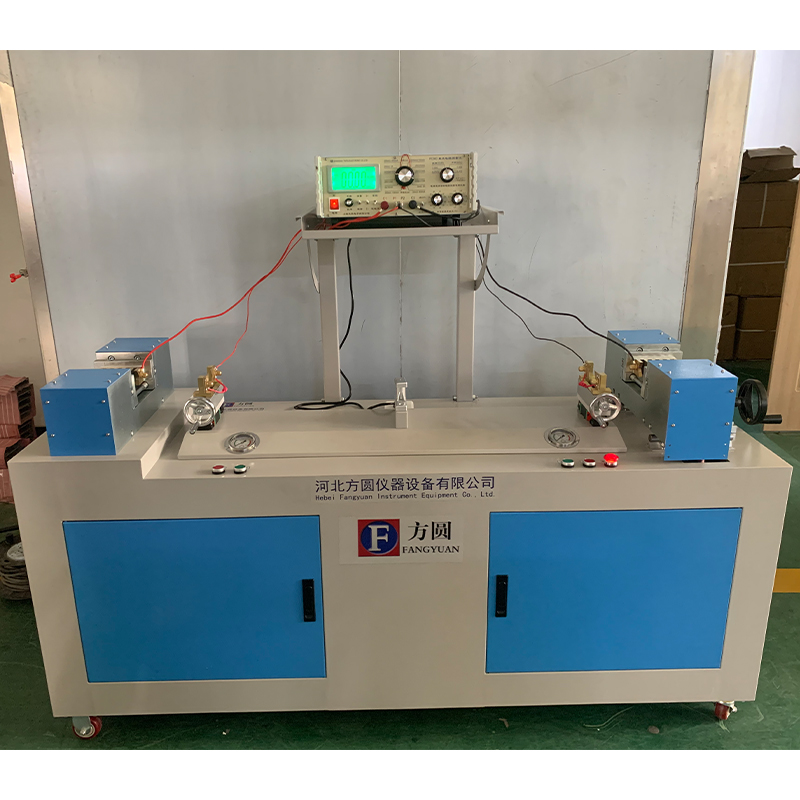

tensile tester machine factories

Meeting Market Demands

The increasing variety of materials and specifications in industries such as aerospace, automotive, and consumer products has led to a surge in demand for high-quality tensile testing machines. Tensile tester machine factories must continuously evolve to accommodate the diverse needs of their clients. Customizable machines that can handle various sample types and test conditions are becoming more prevalent.

Additionally, factories are increasingly focusing on sustainability. Eco-friendly manufacturing practices and energy-efficient machines are crucial as businesses aim to reduce their carbon footprint. This shift not only reflects better corporate responsibility but also aligns with global trends towards sustainability in engineering and manufacturing.

Global Reach and Collaboration

Tensile tester machine factories are often part of a global supply chain. They collaborate with material suppliers, research institutions, and end-users to develop tailored solutions that address specific testing requirements. This global reach allows for knowledge and technology transfer, further enhancing the industry’s capabilities.

Moreover, many factories offer training and technical support, ensuring that clients can optimally use their testing machines. This support is vital as new materials and testing standards emerge, requiring continuous education and adaptation.

Conclusion

Tensile tester machine factories play an indispensable role in modern material testing, driving innovation and ensuring the production of high-quality, reliable testing equipment. As industries continue to evolve, these factories will be crucial in adapting to new materials, testing methods, and global standards. By fostering advancements in technology and maintaining a commitment to quality and sustainability, tensile tester machine factories will remain integral to the future of material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy