Leading Manufacturer of High-Quality Tensile Testing Machines for Accurate Material Evaluation

Understanding Tensile Tester Machine Manufacturers

In the realm of material testing, tensile testing is one of the most essential procedures used to evaluate the mechanical properties of materials. This process not only helps in determining a material's strength but also its ductility, toughness, and elasticity, which are critical attributes in various industries, from construction to manufacturing. As a result, the demand for high-quality tensile testing machines has led to the rise of specialized manufacturers focused solely on producing these vital testing instruments.

What is a Tensile Tester Machine?

A tensile tester, also known as a tensile testing machine or universal testing machine, is designed to apply a controlled tensile load to a material sample until it fails. By measuring the force and elongation during the test, users can calculate critical parameters such as yield strength, ultimate tensile strength, elongation at break, and reduction of area. These measurements are crucial for quality assurance and ensuring that materials can withstand the required loads in their intended applications.

Choosing the Right Manufacturer

When searching for a tensile tester machine, it’s essential to select a manufacturer that meets your requirements in terms of quality, reliability, and technical support. Here are several factors that can help guide your decision

1. Quality of Equipment A reputable manufacturer should offer machines that adhere to industry standards, such as ASTM and ISO guidelines. This ensures that the testing results are valid and comparable across different laboratories and industries.

2. Customization Options Different materials and applications require varying testing methods. Look for manufacturers that provide customizable solutions to accommodate specific needs, including load capacities, testing speeds, and various gripping systems.

3. Technology and Features Modern tensile testing machines are equipped with advanced software and digital indicators that provide accurate measurements and automated data collection. Manufacturers that integrate cutting-edge technology often enhance the efficiency and accuracy of testing processes.

4. Technical Support and After-Sales Service The relationship with the manufacturer should extend beyond the initial purchase. Reliable technical support, including installation, calibration, and maintenance services, is essential for the longevity of the testing equipment.

tensile tester machine manufacturer

5. Industry Experience Longevity and experience in the field can be indicators of a manufacturer’s reliability. Companies that have been in the business for many years are likely to have proven systems in place and feedback from a variety of customers.

Leading Manufacturers in the Industry

Several manufacturers have established a strong reputation in the tensile testing market

- Instron A global leader in materials testing, Instron offers a wide range of tensile testing machines designed for various applications. They are known for innovation and high-quality, user-friendly technology.

- MTS Systems Corporation With a comprehensive portfolio in material testing equipment, MTS specializes in both mechanical and hydraulic tensile testing systems, catering to a variety of industries including aerospace, automotive, and biomedical.

- Shimadzu Corporation A prominent name in analytical and testing instruments, Shimadzu provides advanced tensile testing machines that combine precision engineering with sophisticated software solutions.

- ZwickRoell This German manufacturer is renowned for its meticulous engineering and testing accuracy. ZwickRoell’s tensile testers are widely used across various sectors, ensuring extensive adaptability for users.

- ADMET Focused on simplicity and ease of use, ADMET provides affordable and effective tensile testing solutions, particularly for educational institutes and small businesses.

Conclusion

In conclusion, tensile testing is an indispensable process in material science, and the importance of selecting a quality tensile tester machine manufacturer cannot be overstated. By assessing factors such as equipment quality, support services, and industry experience, engineers and quality managers can make informed choices that ultimately ensure the integrity and safety of the products they produce. With advancements in technology, the future of tensile testing looks promising, providing opportunities for enhanced material performance and innovation across numerous sectors.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

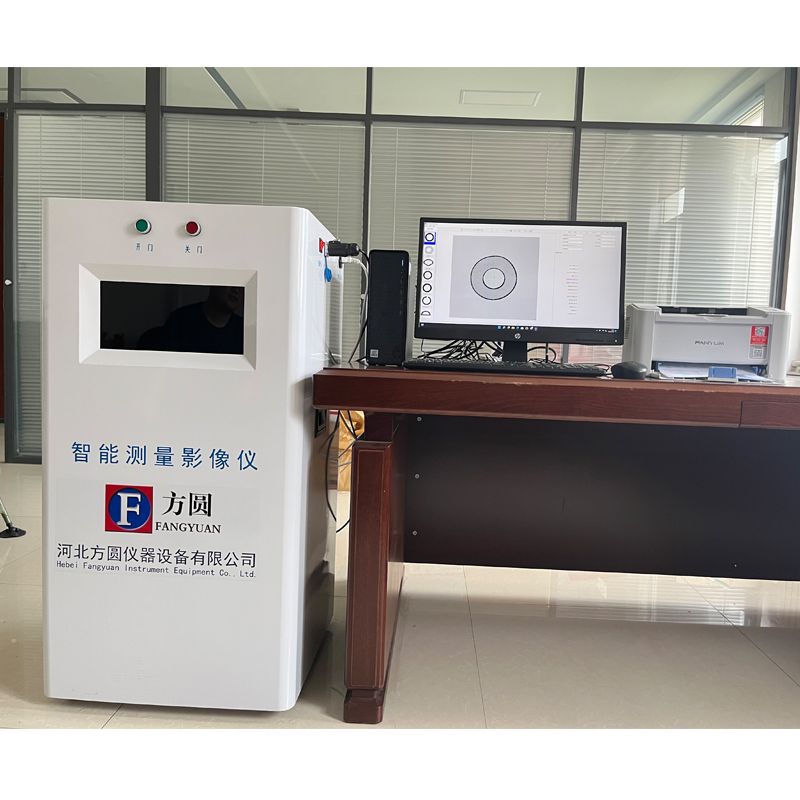

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy