Leading Manufacturers of Tensile Testing Equipment for Accurate Material Analysis

Tensile Tester Manufacturers A Key Component in Material Testing

In the realm of material testing, the importance of tensile testers cannot be overstated. These machines, designed to measure the tensile strength of various materials, are crucial in industries ranging from manufacturing to construction, aerospace, and more. As demand for accurate and reliable testing increases, so does the need for quality tensile tester manufacturers who can provide advanced equipment suited to a wide array of applications.

Tensile testers operate on the principle of applying a controlled force to a sample until it deforms or breaks, thus providing valuable data on the material's properties such as tensile strength, elongation, and stiffness. This information is vital not just for quality control, but also for research and development in engineering and materials science.

The Landscape of Tensile Tester Manufacturers

The market for tensile testers is diverse, with numerous manufacturers offering a range of options. Established companies are continuously innovating to meet industry standards and specifications. Some of the key players in this sector have been around for decades, while new entrants are often equipped with cutting-edge technology to attract businesses looking for modern solutions.

When choosing a tensile tester manufacturer, several factors come into play. Firstly, the machine's accuracy and reliability are paramount. High-quality manufacturers utilize advanced technology and robust design principles to ensure their equipment delivers precise measurements consistently over time. This reliability is especially critical in sectors like aerospace and automotive, where material performance is directly tied to safety.

Secondly, after-sales support and service can significantly influence a buyer's experience. A reputable manufacturer will provide comprehensive training, maintenance, and quick response times for repairs, ensuring that customers can keep their equipment operational with minimal downtime.

Technological Advancements in Tensile Testing

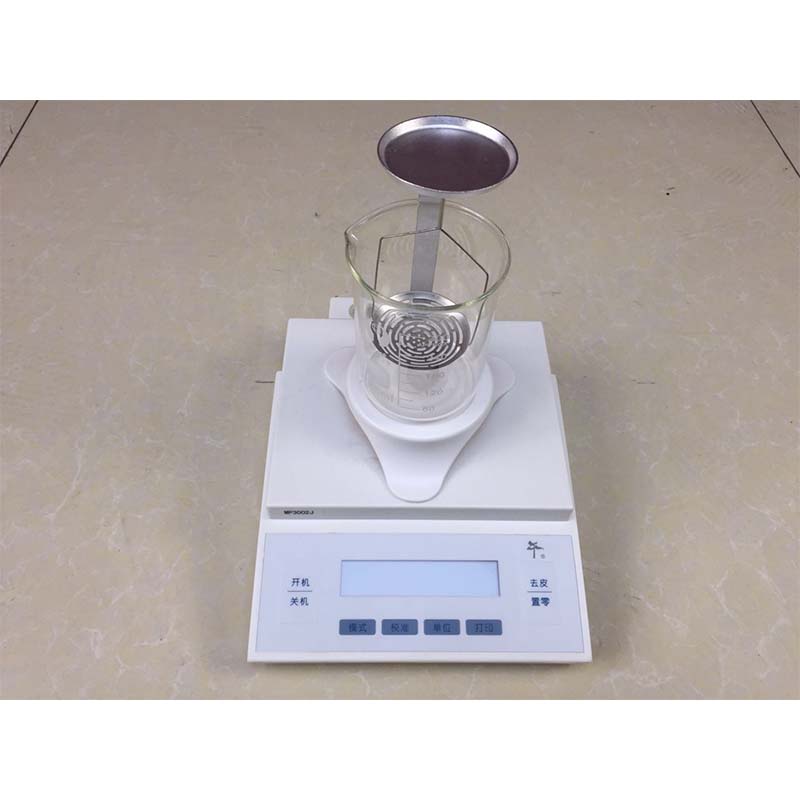

tensile tester manufacturers

Recent advancements in technology have transformed the landscape of tensile testing. Manufacturers are increasingly incorporating digital interfaces, automation, and connectivity features into their machines. For example, many modern tensile testers now come equipped with software that allows for real-time data analysis, making it easier for users to interpret results and document findings.

Some manufacturers are also incorporating artificial intelligence and machine learning into their systems, enabling predictive maintenance and enhanced testing parameters that can adapt based on the material being tested. This not only improves efficiency but significantly enhances the accuracy of the results.

Global Expansion and Demand

As industries evolve and global markets expand, the demand for tensile testing equipment continues to rise. Emerging markets, particularly in Asia and Africa, are seeing increased investments in manufacturing and infrastructure, which in turn drives the need for reliable material testing solutions. Manufacturers must therefore focus on scalability and adaptability of their products to cater to various industry requirements across different regions.

Moreover, sustainability is becoming a focal point in manufacturing processes. Manufacturers that produce eco-friendly tensile testers — designed with energy efficiency in mind or made from sustainable materials — can attract a growing segment of environmentally conscious customers.

Conclusion

The role of tensile tester manufacturers is crucial in ensuring the integrity and quality of materials used across various industries. As technology continues to advance and global demand increases, manufacturers will need to prioritize reliability, support, and innovation to stay competitive. For businesses looking to invest in tensile testing equipment, understanding the landscape and evaluating manufacturers based on these key criteria is essential to ensure they acquire machines that meet their specific needs and standards.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy