tensile testers factories

Understanding Tensile Testers A Crucial Tool in Material Testing

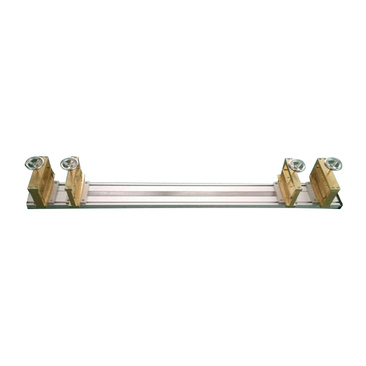

Tensile testers, also known as tensile testing machines or universal testing machines, are essential instruments in the field of material science and engineering. These devices play a significant role in determining the mechanical properties of materials by measuring how they respond to tensile forces. In industries ranging from aerospace to construction, tensile testers provide critical data that helps engineers and manufacturers ensure product safety and reliability.

The Importance of Tensile Testing

Tensile testing is a fundamental process used to assess how materials behave when subjected to pulling forces. The test involves stretching a specimen until it fails, allowing for the measurement of key parameters such as ultimate tensile strength, yield strength, elongation, and modulus of elasticity. These properties are vital for determining a material's suitability for specific applications. For instance, a material with high tensile strength is preferred for structural components, whereas materials with good elongation are required in applications where flexibility is needed.

The results obtained from tensile tests are crucial for compliance with industry standards and regulatory requirements. Many sectors require specific performance criteria to be met before materials can be approved for use. Tensile testers provide the empirical data that verifies compliance with standards set by organizations such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Features of Modern Tensile Testers

Modern tensile testers have evolved significantly over the years, incorporating advanced technologies and features. Most contemporary machines are equipped with digital interfaces, allowing for precise control and easy data acquisition. Key features to look for in a tensile tester include

tensile testers factories

2. Accuracy and Precision The accuracy of measurements is paramount in tensile testing. High-quality tensile testers offer precise load measurements and displacement readings, often with the ability to perform tests according to different standards.

3. Data Acquisition Software Many machines come with specialized software that allows for real-time data monitoring, analysis, and reporting. This software can often generate detailed reports, including graphs and statistics, which are invaluable for research and quality control.

4. Multi-Functionality Advanced tensile testers can perform various tests beyond simple tension tests. These may include compression tests, shear tests, and bending tests, making them versatile tools in material testing labs.

Selecting the Right Tensile Tester

When choosing a tensile tester, factories must consider the specific materials they will be testing and the mechanical properties of interest. Factors such as the type of material (metal, plastic, rubber, etc.), the size of specimens, and the required test standards should all influence the decision. Additionally, it is essential to consider the machine's user-friendliness, maintenance requirements, and customer support from manufacturers.

Companies should work with reputable manufacturers that specialize in tensile testing equipment. These manufacturers typically provide comprehensive after-sales support, including installation, training, and maintenance services. This ensures that the tensile testers operate efficiently and yield reliable test results over their lifespan.

Conclusion

In summary, tensile testers are indispensable tools in material science, providing critical data that informs engineering decisions and ensures product integrity. As industries continue to prioritize safety and reliability, the demand for high-quality tensile testers will remain strong. By investing in the right tensile testing equipment, factories can enhance their material testing capabilities and maintain compliance with rigorous industry standards, ultimately leading to better products and safer structures.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy