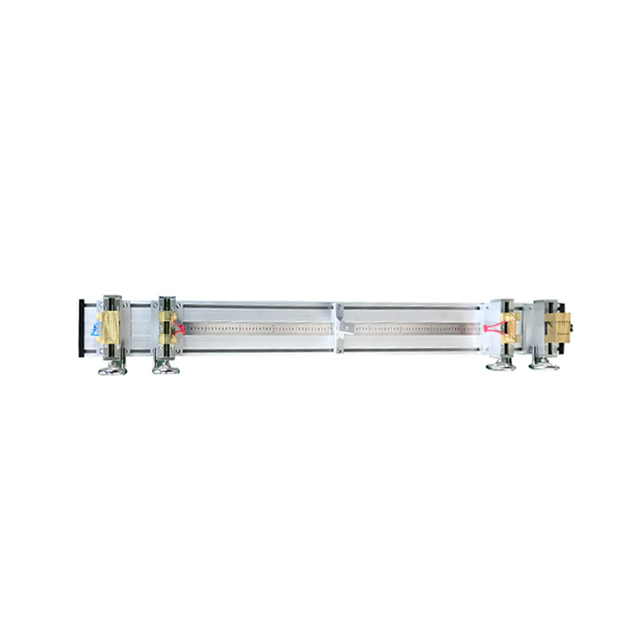

tensile testers factory

The Importance of Tensile Testers in Material Testing

Tensile testers, also known as tensile testing machines or tensile strength testers, play a crucial role in the field of material science and engineering. They are essential tools used to measure the mechanical properties of materials, particularly their tensile strength, elongation, and other related characteristics. This article explores the significance of these testing machines, their applications, and the factors influencing the choice of a tensile testers factory for procurement.

Understanding Tensile Testing

Tensile testing involves subjecting a material specimen to a uniaxial tensile load until failure. The test is crucial for determining various properties of materials, including yield strength, ultimate tensile strength, and ductility. During the test, the material is pulled apart, and the forces and elongations at different stages are recorded. This data is then used to create stress-strain curves, which are fundamental for understanding a material's performance under load.

Applications of Tensile Testers

Tensile testers find applications across various industries, including manufacturing, construction, automotive, aerospace, and research. Some of the primary uses of tensile testers include

1. Quality Control Manufacturers use tensile testing to ensure that their materials meet specific standards and requirements. By regularly testing materials, manufacturers can avoid costly failures and improve product quality.

2. Material Development In research and development, tensile testing is essential for evaluating new materials or composites. By understanding how materials behave under stress, engineers can design better products with enhanced performance characteristics.

4. Compliance with Standards Many industries have strict regulations regarding material properties. Tensile testing helps companies ensure compliance with national and international standards, such as ASTM and ISO.

tensile testers factory

Choosing a Tensile Testers Factory

When selecting a tensile testers factory, several factors must be considered to ensure that the equipment meets specific requirements

1. Quality of Equipment The accuracy and precision of tensile testing machines are paramount. A reputable factory should provide equipment that adheres to the highest standards of manufacturing and testing.

2. Range of Models A good factory will offer a wide range of tensile testers suitable for various applications, from basic models for educational purposes to advanced machines with sophisticated software for comprehensive analysis.

3. Customization Options Different industries may have specific requirements for tensile testing. A factory that offers customization options allows businesses to tailor machines to their unique needs, enhancing operational efficiency.

4. Technical Support and Service After-sales support is critical when investing in testing equipment. Choose a factory known for its customer service and technical support, ensuring assistance is available when issues arise.

5. Pricing and Warranty While price shouldn't be the sole deciding factor, it is essential to find a balance between cost and quality. Additionally, look for warranties that demonstrate the manufacturer's confidence in their product.

Conclusion

Tensile testers are invaluable tools that support quality testing and material development across various industries. The insights gained from tensile testing help engineers design safer and more efficient products, ultimately benefiting consumers and advancing technology. When selecting a tensile testers factory, consider quality, range, customization, support, and pricing to ensure investment in a reliable and effective testing solution. In an ever-evolving marketplace, the importance of rigorous material testing and the role of tensile testers cannot be overstated.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy