tensile testers for sale supplier

Understanding Tensile Testers A Guide for Buyers

In the realm of materials science and engineering, tensile testers play a crucial role in assessing the mechanical properties of materials. These devices are essential for testing the tensile strength, elongation, and overall durability of various materials, including metals, plastics, and textiles. If you are in the market for tensile testers for sale, understanding their types, features, and suppliers will help you make an informed decision.

What Is a Tensile Tester?

A tensile tester, also known as a tensile testing machine, is used to perform tensile tests on materials to determine how they behave under tension. The primary objective is to measure the force required to stretch a sample until it breaks, while also recording other critical properties such as yield strength, ultimate tensile strength, and ductility.

Types of Tensile Testers

Tensile testers come in various forms, each designed for specific applications. Here are some common types you might encounter

1. Electronic Tensile Testers These are widely used due to their precision and ease of operation. They often feature digital displays and computer interfaces for data collection and analysis.

2. Hydraulic Tensile Testers Known for their ability to handle larger specimens and higher loads, hydraulic testers are common in industrial applications where heavy-duty materials are being tested.

3. Mechanical Tensile Testers These testers operate using mechanical means to apply force, providing a more straightforward setup but may lack the precision and data analysis capabilities of electronic systems.

4. Portable Tensile Testers Ideal for field testing, portable testers are lightweight and designed for quick assessments of materials without the need for a laboratory setup.

Key Features to Look For

When shopping for tensile testers, consider the following features

- Load Capacity Ensure the tester can handle the maximum load of the materials you intend to test.

tensile testers for sale supplier

- Accuracy and Resolution Look for devices that provide high accuracy and resolution in measurements for reliable results.

- Software Compatibility Many modern testers come with software for data analysis. Compatibility with your existing systems can enhance productivity.

- Sample Grip Design The design of the grips can significantly impact testing outcomes. Ensure they are appropriate for the types of materials you will be testing.

- Compliance and Standards Check if the tester meets industry standards (e.g., ASTM, ISO) to ensure your tests are valid and recognized.

Selecting a Supplier

Finding a reliable supplier for tensile testers is crucial. Here are some tips

1. Research Supplier Reputation Check reviews, industry rankings, and testimonials to gauge the reliability of the supplier.

2. Explore Product Range A supplier offering a wide range of tensile testers can provide options that match your specific needs.

3. Customer Support Opt for suppliers who offer strong customer support, including installation assistance, calibration services, and readily available spare parts.

4. Pricing and Warranty Compare prices but also pay attention to warranty terms, which could save you money in case of mechanical failures.

Conclusion

Investing in a tensile tester is a significant decision that can impact your materials testing accuracy and efficiency. By understanding the types, features, and selecting a reputable supplier, you can ensure that you choose the best tensile testing equipment suited for your applications. Whether you are working in a lab or an industrial setting, high-quality tensile testers are invaluable tools for quality assurance and material performance evaluation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

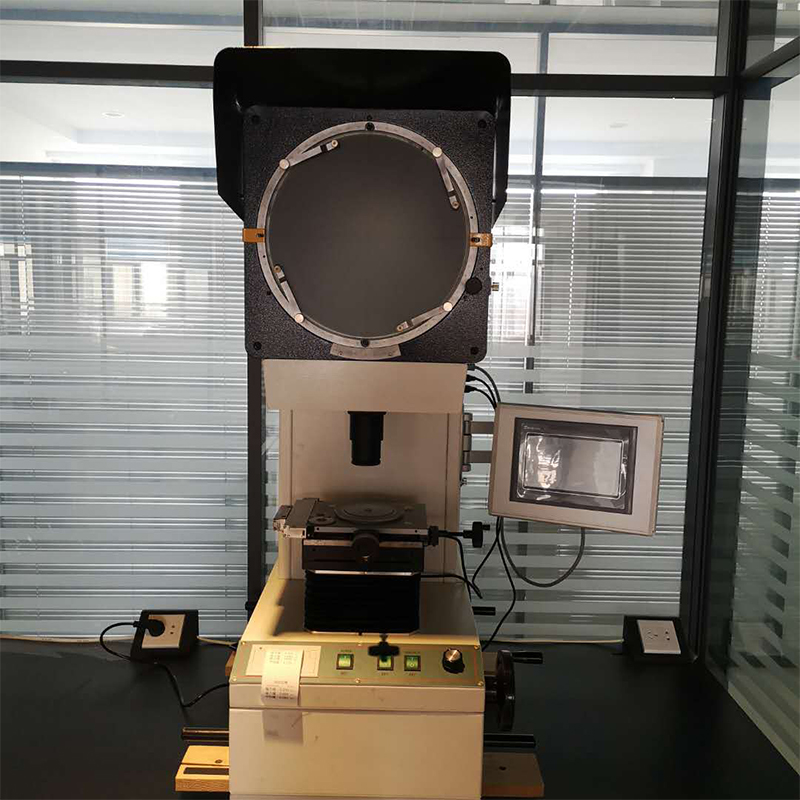

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy