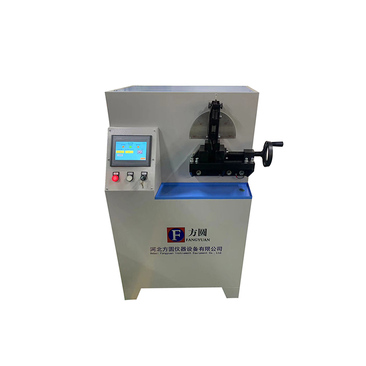

tensile testers for sale supplier

The Importance of Tensile Testers in Material Testing

In the field of materials science, understanding the mechanical properties of materials is paramount. One of the most effective ways to measure these properties is through tensile testing, which provides critical insights into a material's strength, ductility, and overall performance under stress. Tensile testers, also known as universal testing machines (UTMs), play a crucial role in this process, and many suppliers offer various models for sale to meet diverse testing needs.

Tensile testing involves applying a controlled tensile force to a material specimen until it fails. The results of this test can indicate key characteristics such as yield strength, ultimate tensile strength, elongation, and reduction of area. These properties are indispensable for engineers and material scientists as they make crucial decisions in design and quality assurance processes.

Types of Tensile Testers

There are several types of tensile testers available on the market, each designed for specific applications

1. Electromechanical Tensile Testers These are the most common types of tensile testers. They use electric motors to apply the load, offering precision and flexibility for a wide range of materials, including metals, plastics, and textiles.

2. Hydraulic Tensile Testers These testers are ideal for high-capacity applications, capable of testing larger materials or those that require significant force before breaking. They are commonly used in heavy industries and materials testing laboratories.

3. Micro and Nano Tensile Testers For applications requiring precise measurements at the micro or nanoscale level, specialized testers are available. These are used in advanced materials research and development, particularly for thin films and nanomaterials.

tensile testers for sale supplier

Selecting the Right Supplier

When considering the purchase of a tensile tester, choosing a reliable supplier is essential. Factors to consider include

- Reputation and Expertise Look for suppliers that specialize in material testing equipment and have a proven track record within the industry. Reading reviews and testimonials can help gauge their reliability.

- Range of Products A good supplier offers a variety of tensile testers suited for different applications and budgets. They should also provide additional accessories and software for data analysis.

- Customer Support and Service A knowledgeable support team is invaluable, offering assistance during installation, operation, and troubleshooting. Furthermore, consider suppliers that provide calibration services and ongoing maintenance.

- Training and Resources Comprehensive training programs can help users become proficient in operating the equipment and understanding test results. Look for suppliers that offer workshops, webinars, or tutorials.

Conclusion

In summary, tensile testers are vital tools in the field of materials testing, providing crucial data that informs design and safety decisions across various industries. By choosing the right supplier who offers quality equipment, adequate support, and the necessary training, businesses can ensure they obtain reliable results that meet their testing needs. As technology continues to evolve, keeping abreast of advancements in tensile testing will further enhance material performance assessment, leading to innovation and safety in applications ranging from construction to aerospace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy