tensile tester shear strength company

Understanding Tensile Testers and Shear Strength in Material Analysis

In the world of material testing, the need for precision and reliability is paramount. Various testing methods are employed to assess the mechanical properties of materials, among which tensile testing and shear strength determination stand out. These tests are essential in industries where material integrity is critical, including construction, aerospace, automotive, and manufacturing. Companies specializing in tensile testers and shear strength measurement provide vital tools for engineers and researchers to ensure that materials can withstand the pressures they will face in real-world applications.

The Importance of Tensile Testing

Tensile testing, also known as tension testing, is one of the oldest and most widely used methods for determining the behavior of materials under axial loads. During a tensile test, a sample is subjected to a controlled pulling force until failure occurs. This process provides key data points such as yield strength, ultimate tensile strength, and elongation, which help in understanding how a material will perform under various types of stress.

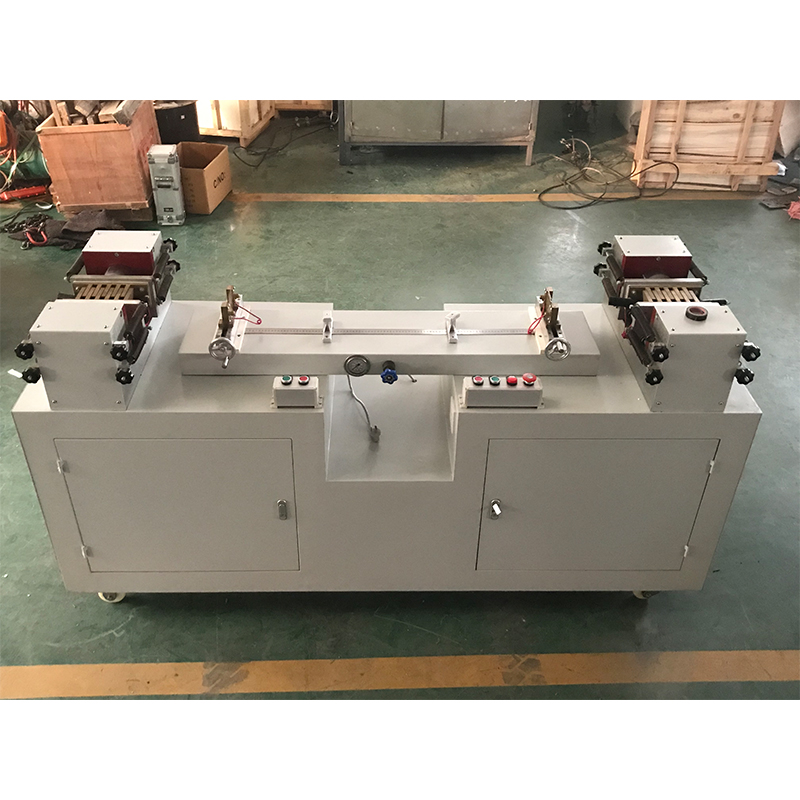

The equipment used in tensile testing, often referred to as a tensile tester, consists of a test frame equipped with grips to hold the material sample in place, along with sensors to measure force and elongation. Advanced computer software is typically integrated into these systems, allowing for real-time data collection and analysis. Companies that manufacture tensile testers focus on delivering solutions that optimize accuracy and speed, ensuring compliance with industry standards such as ASTM and ISO.

Shear Strength and Its Measurement

While tensile tests provide insights into a material's ability to resist stretching forces, shear strength testing focuses on the material's ability to withstand forces that attempt to cause it to slide or fracture along a plane. Shear strength is a critical factor in applications like bolted joints, welds, and adhesive bonds, where materials are subject to forces that can cause them to fail along their interfaces.

tensile tester shear strength company

The measurement of shear strength can be accomplished using various methods, including shear testing rigs that apply a load parallel to the test specimen. Shear tests can be carried out on different materials, including metals, plastics, and composites, with results guiding design decisions and quality control measures.

Several companies are leading the charge in offering advanced shear strength testing solutions. These organizations develop apparatus that can accommodate various materials and configurations, including shear beams and torsion testing machines. The integration of digital technology allows for improved data accuracy and the ability to simulate real-world conditions, streamlining the testing process and enhancing the overall reliability of results.

The Role of Technology in Testing

As technology continues to evolve, so does the landscape of material testing. Companies in the tensile testing and shear strength space are increasingly incorporating automation, artificial intelligence, and machine learning into their systems. These advancements facilitate faster test cycles, improved accuracy, and the ability to analyze vast amounts of data effortlessly. This trend is particularly significant as industries strive for higher quality standards and seek to innovate rapidly.

Furthermore, the integration of these technologies helps in predictive maintenance, allowing firms to foresee potential failures in materials before they occur. By implementing sophisticated testing machines, organizations can effectively reduce downtime and costs associated with material failure.

Conclusion

In summary, tensile testers and shear strength measurement tools are indispensable in ensuring material quality and integrity in various industrial applications. The rigorous testing of materials ensures that products meet safety and performance standards, ultimately protecting end-users and promoting confidence in the materials used. As technology continues to progress, the capabilities of these testing systems will only expand, paving the way for new innovations and improvements in material science and engineering. Companies focused on developing cutting-edge tensile testing and shear strength solutions will remain at the forefront of this essential field, driving advancements that benefit numerous industries worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy